| Availability: | |

|---|---|

| Quantity: | |

A stainless-steel double rotor valve typically has a double rotor design, which which means it contains two rotating elements that work together to control the flow of the substance passing through the valve.

The primary function of the double rotor metering valve is to precisely control the flow of gases or liquids. The rotation of the rotors allows for fine-tuning of the flow rate.

A double rotor metering valve consists of several key components that work together to control the flow of gases or liquids with precision that are valve body, rotors, rotor shaft, actuation mechanism, seals, inlet and outlet port and flow channels and pressure equalization.

A double rotor metering valve works by utilizing two rotating elements, known as rotors, to control the flow of gases or liquids through the valve. The rotors are mounted inside the valve housing body, the rotors are positioned in a way that their rotation determines the flow rate. The liquid and gases enter through the inlet port and exit through the outlet port as this port are connected to the larger system. The rotation of the rotor is controlled by the actuation mechanism equipped in the valve and the rotors modulates the flow of the liquid and gases passing through it. Seals are used for preventing leakage between rotor and valve body.

JN-XW 23 1001

JONENG

8421219990

Sanitary Grade 316L Stainless Steel JN-XW 23 1001 Butterfly Valve with Double Dosage

A stainless-steel double rotor valve typically has a double rotor design, which which means it contains two rotating elements that work together to control the flow of the substance passing through the valve.

The primary function of the double rotor metering valve is to precisely control the flow of gases or liquids. The rotation of the rotors allows for fine-tuning of the flow rate.

A double rotor metering valve consists of several key components that work together to control the flow of gases or liquids with precision that are valve body, rotors, rotor shaft, actuation mechanism, seals, inlet and outlet port and flow channels and pressure equalization.

A double rotor metering valve works by utilizing two rotating elements, known as rotors, to control the flow of gases or liquids through the valve. The rotors are mounted inside the valve housing body, the rotors are positioned in a way that their rotation determines the flow rate. The liquid and gases enter through the inlet port and exit through the outlet port as this port are connected to the larger system. The rotation of the rotor is controlled by the actuation mechanism equipped in the valve and the rotors modulates the flow of the liquid and gases passing through it. Seals are used for preventing leakage between rotor and valve body.

Working Principles

The working principle of a double rotor metering valve involves the controlled rotation of two internal rotors to regulate the flow of gases or liquids.

The double rotor metering valve works by adjusting the position of two rotors within the valve body, controlling the flow of substances in a precise and controlled manner. The actuation mechanism and valve design ensure accuracy and reliability in various industrial applications.

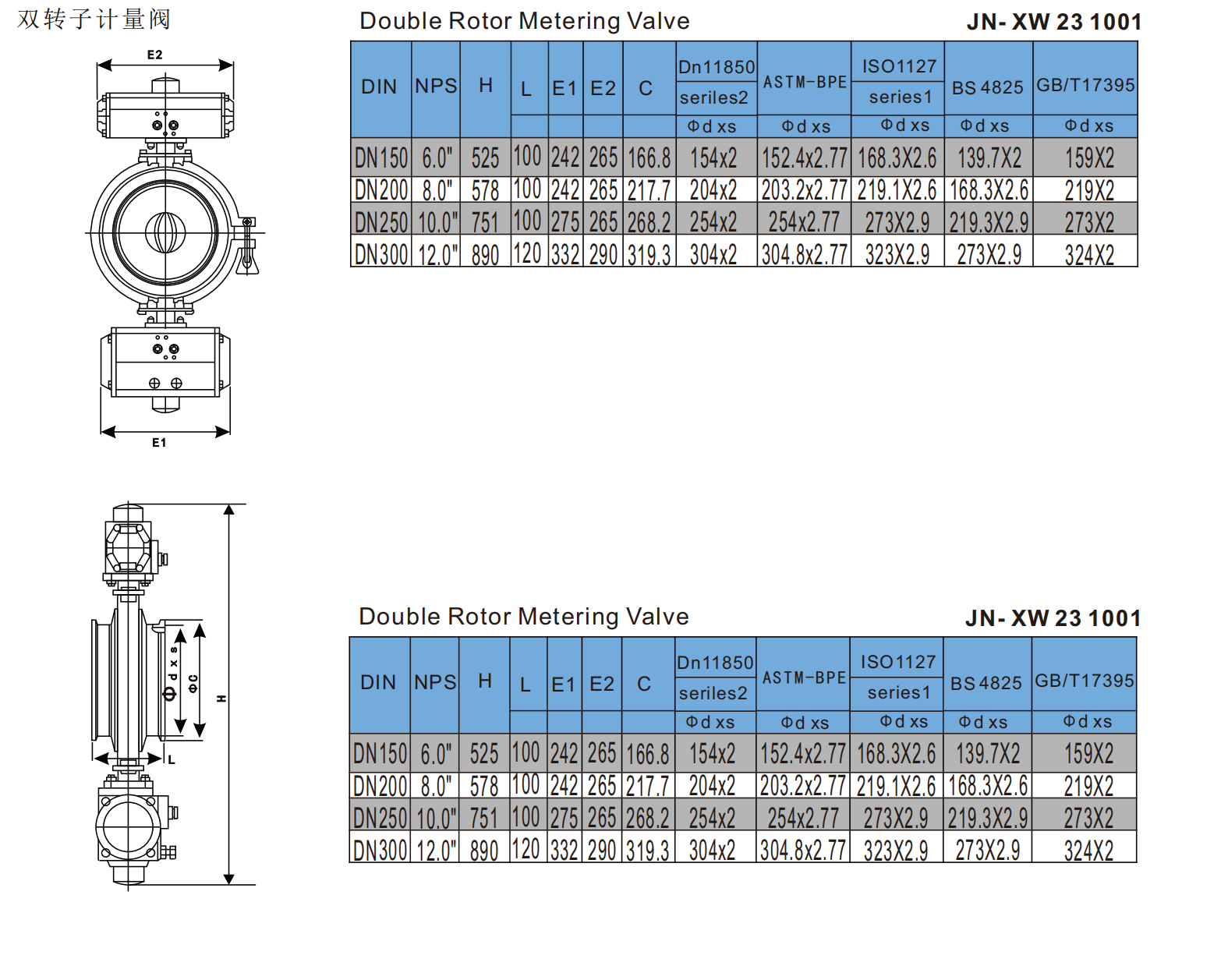

Stainless Steel Metering Valve Specification Chart

Sizes available | 3 "-16" |

Max pressure | up to 10 bar |

End connection | Flanged, threaded, clamped |

Material | AISI316L OR AISI304L |

Seals | Silicone, Viton, PTFE, EPDM |

Standard | Manual or Pneumatic |

Temperature range | 3A, SMS, ISO |

Application

Stainless steel double rotor metering valves find applications in various industries where precise control of the flow of gases or liquids is crucial like food, beverage, dairy, pharmaceuticals, chemical, and other food processing industry.

Working Principles

The working principle of a double rotor metering valve involves the controlled rotation of two internal rotors to regulate the flow of gases or liquids.

The double rotor metering valve works by adjusting the position of two rotors within the valve body, controlling the flow of substances in a precise and controlled manner. The actuation mechanism and valve design ensure accuracy and reliability in various industrial applications.

Feature and Specification

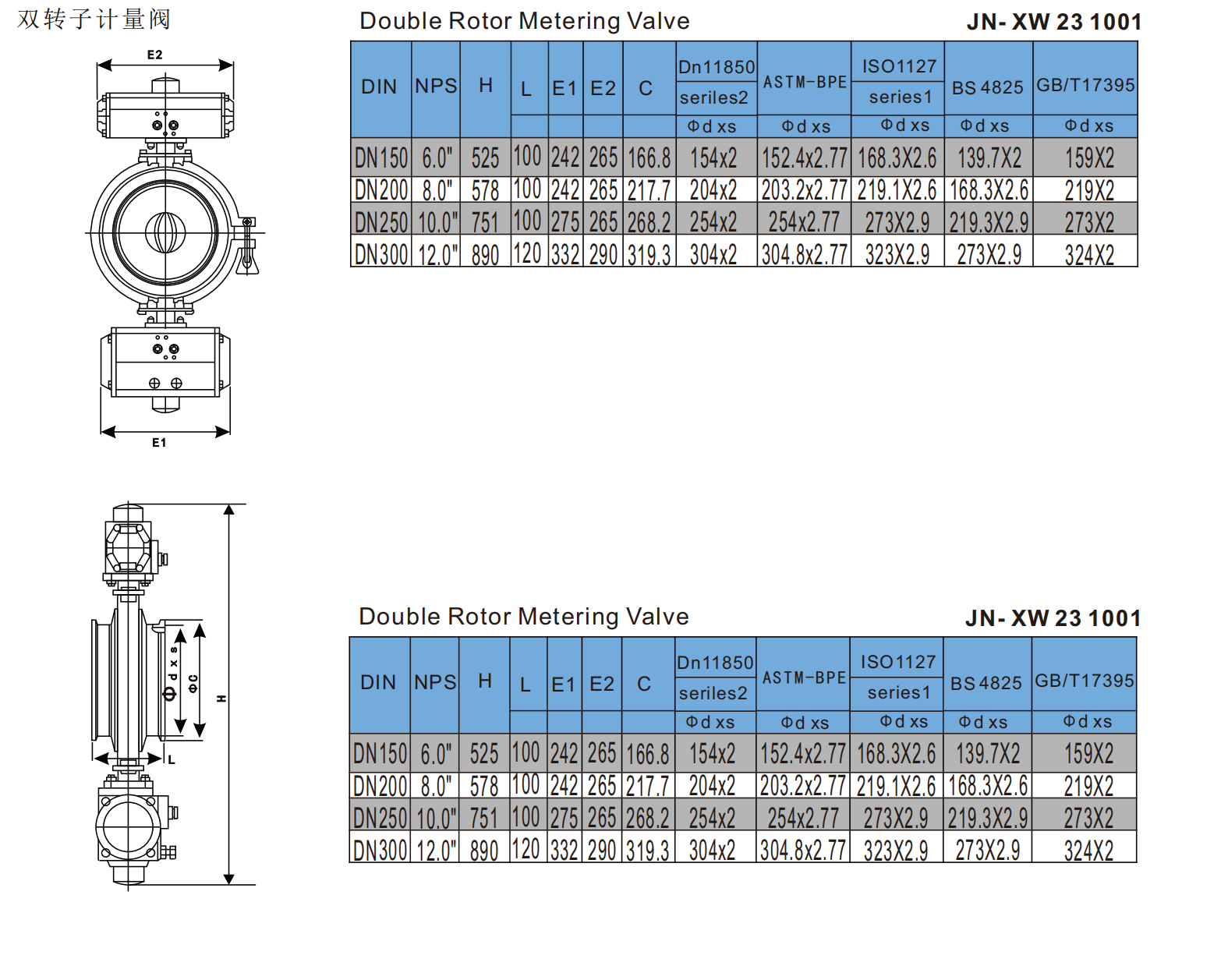

Stainless Steel Metering Valve Specification Chart

Sizes available | 3 "-16" |

Max pressure | up to 10 bar |

End connection | Flanged, threaded, clamped |

Material | AISI316L OR AISI304L |

Seals | Silicone, Viton, PTFE, EPDM |

Standard | Manual or Pneumatic |

Temperature range | 3A, SMS, ISO |

Application

Stainless steel double rotor metering valves find applications in various industries where precise control of the flow of gases or liquids is crucial like food, beverage, dairy, pharmaceuticals, chemical, and other food processing industry.

Sanitary Grade 316L Stainless Steel JN-XW 23 1001 Butterfly Valve with Double Dosage

A stainless-steel double rotor valve typically has a double rotor design, which which means it contains two rotating elements that work together to control the flow of the substance passing through the valve.

The primary function of the double rotor metering valve is to precisely control the flow of gases or liquids. The rotation of the rotors allows for fine-tuning of the flow rate.

A double rotor metering valve consists of several key components that work together to control the flow of gases or liquids with precision that are valve body, rotors, rotor shaft, actuation mechanism, seals, inlet and outlet port and flow channels and pressure equalization.

A double rotor metering valve works by utilizing two rotating elements, known as rotors, to control the flow of gases or liquids through the valve. The rotors are mounted inside the valve housing body, the rotors are positioned in a way that their rotation determines the flow rate. The liquid and gases enter through the inlet port and exit through the outlet port as this port are connected to the larger system. The rotation of the rotor is controlled by the actuation mechanism equipped in the valve and the rotors modulates the flow of the liquid and gases passing through it. Seals are used for preventing leakage between rotor and valve body.

Working Principles

The working principle of a double rotor metering valve involves the controlled rotation of two internal rotors to regulate the flow of gases or liquids.

The double rotor metering valve works by adjusting the position of two rotors within the valve body, controlling the flow of substances in a precise and controlled manner. The actuation mechanism and valve design ensure accuracy and reliability in various industrial applications.

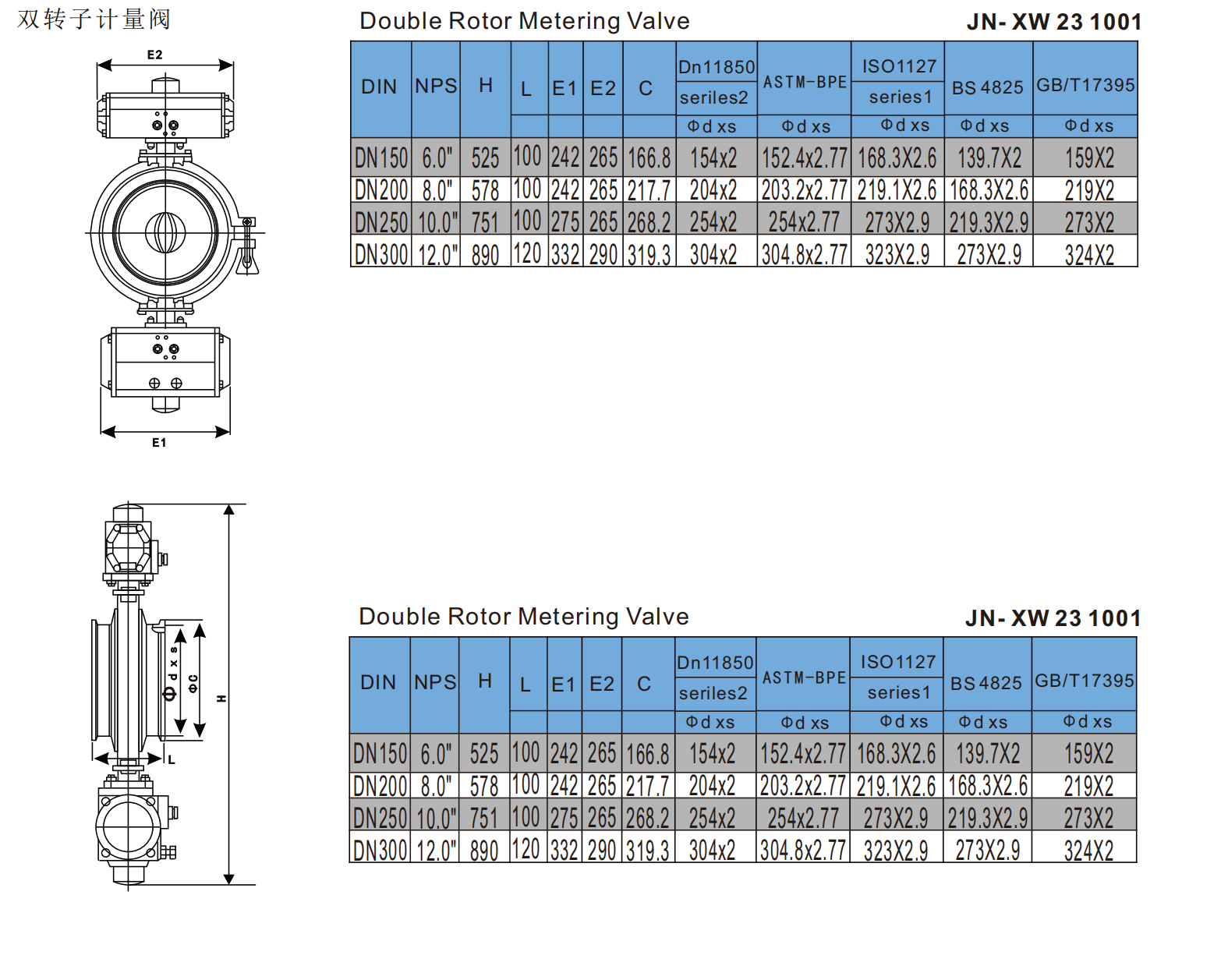

Stainless Steel Metering Valve Specification Chart

Sizes available | 3 "-16" |

Max pressure | up to 10 bar |

End connection | Flanged, threaded, clamped |

Material | AISI316L OR AISI304L |

Seals | Silicone, Viton, PTFE, EPDM |

Standard | Manual or Pneumatic |

Temperature range | 3A, SMS, ISO |

Application

Stainless steel double rotor metering valves find applications in various industries where precise control of the flow of gases or liquids is crucial like food, beverage, dairy, pharmaceuticals, chemical, and other food processing industry.

Working Principles

The working principle of a double rotor metering valve involves the controlled rotation of two internal rotors to regulate the flow of gases or liquids.

The double rotor metering valve works by adjusting the position of two rotors within the valve body, controlling the flow of substances in a precise and controlled manner. The actuation mechanism and valve design ensure accuracy and reliability in various industrial applications.

Feature and Specification

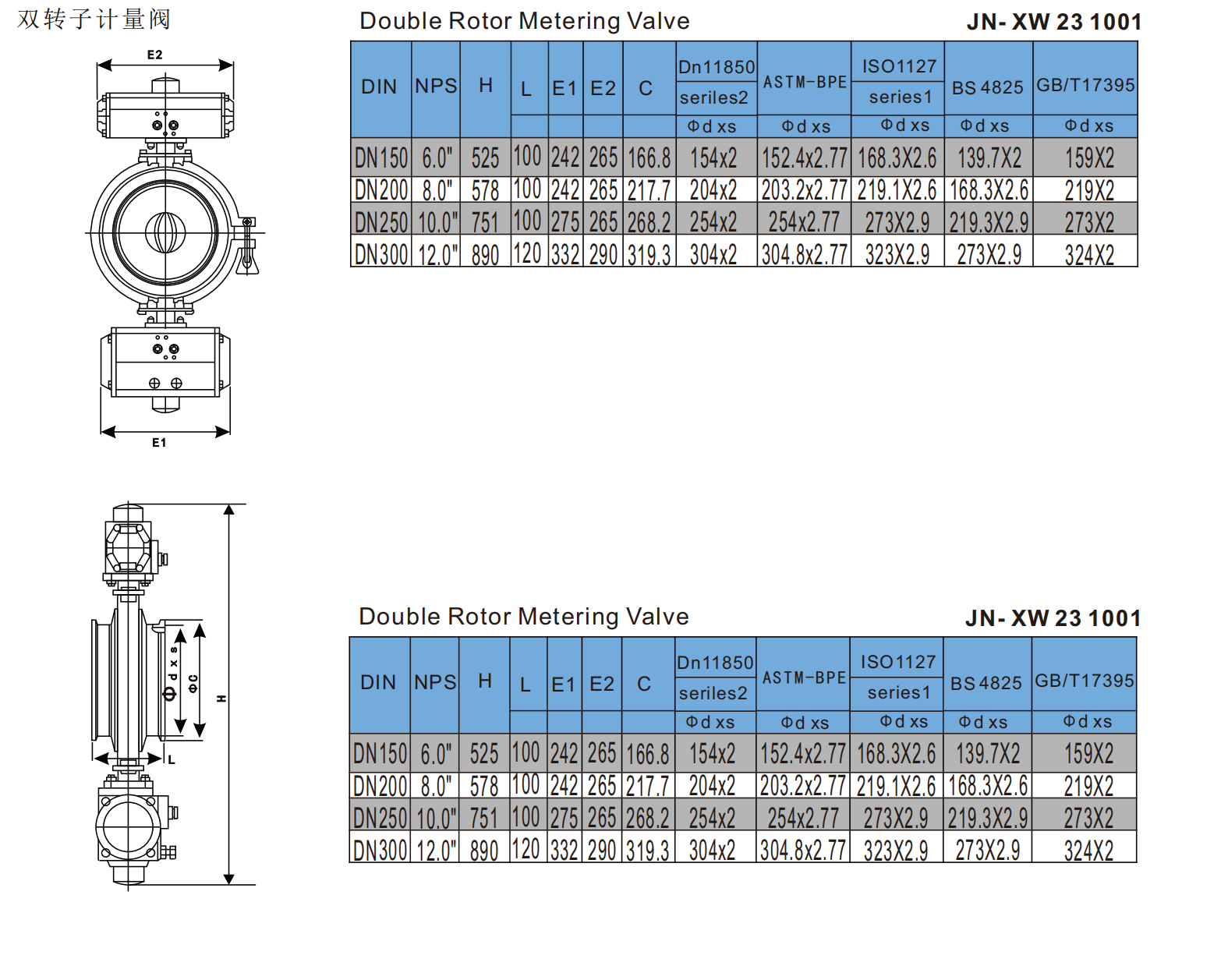

Stainless Steel Metering Valve Specification Chart

Sizes available | 3 "-16" |

Max pressure | up to 10 bar |

End connection | Flanged, threaded, clamped |

Material | AISI316L OR AISI304L |

Seals | Silicone, Viton, PTFE, EPDM |

Standard | Manual or Pneumatic |

Temperature range | 3A, SMS, ISO |

Application

Stainless steel double rotor metering valves find applications in various industries where precise control of the flow of gases or liquids is crucial like food, beverage, dairy, pharmaceuticals, chemical, and other food processing industry.