304 Stainless Steel High Flow Rate Chocolate Rubber Rotary Lobe Pump

The 304 Stainless Steel High Flow Rate Chocolate Rubber Rotary Lobe Pump is a positive displacement pump designed for gentle, high-capacity transfer of viscous chocolate and similar products. Its rubber-coated lobes protect product texture while delivering consistent flow, hygienic handling, and efficient performance in food processing lines.

Working Principles

The lobe pump is consist of a casting housing, shaft, rotors and mechanical seal. Shaft connects the motor and rotors. When motor starts working, the shaft will rotate which makes the rotor to revolve synchronously. Two rotors inside the casing without touching each other but dividing the cavity into several parts gives space for the fluid to fill in. As rotor moves in counter-clockwise directions, it carries the fluid from inlet to discharge port while generating pressure at the discharge port.

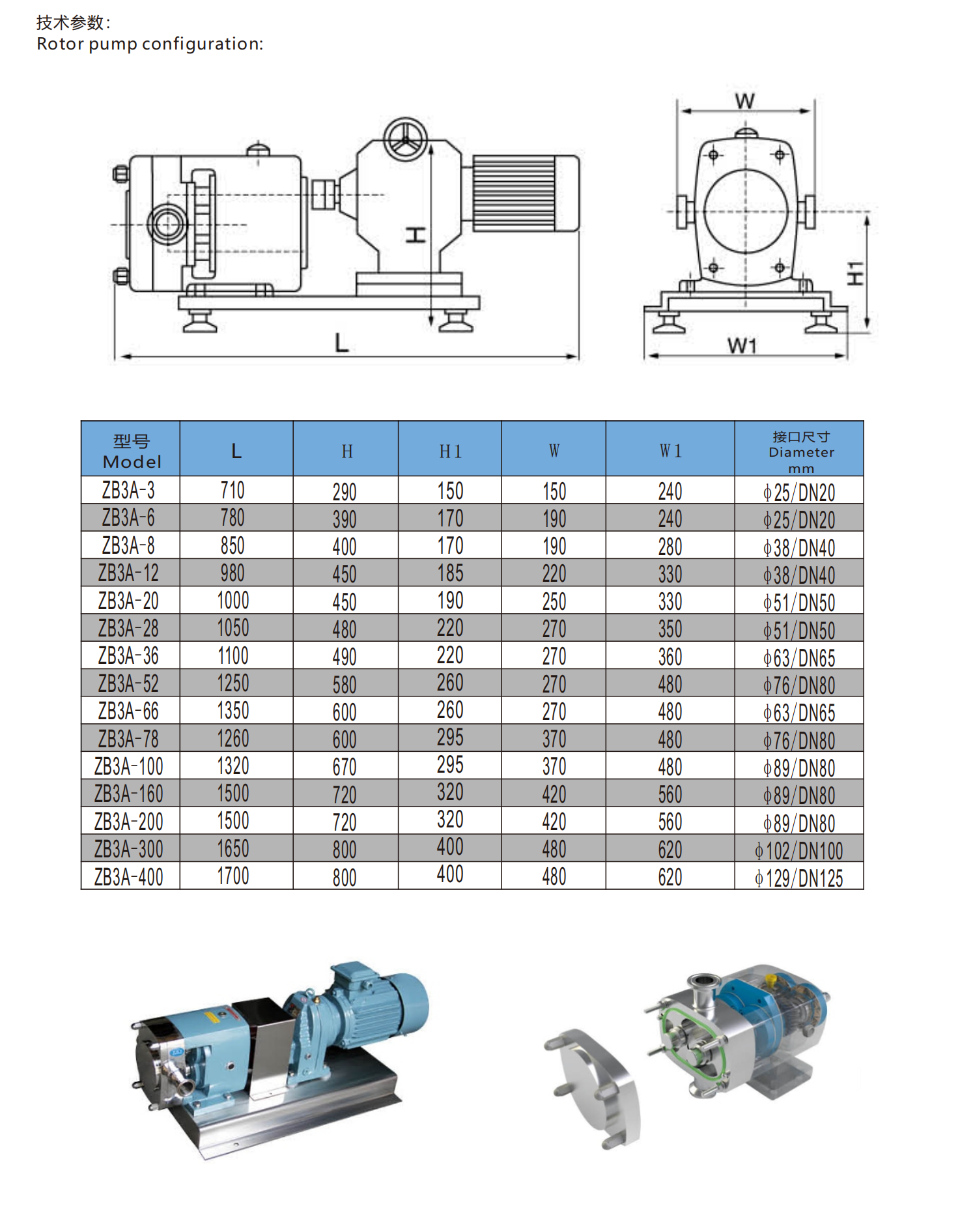

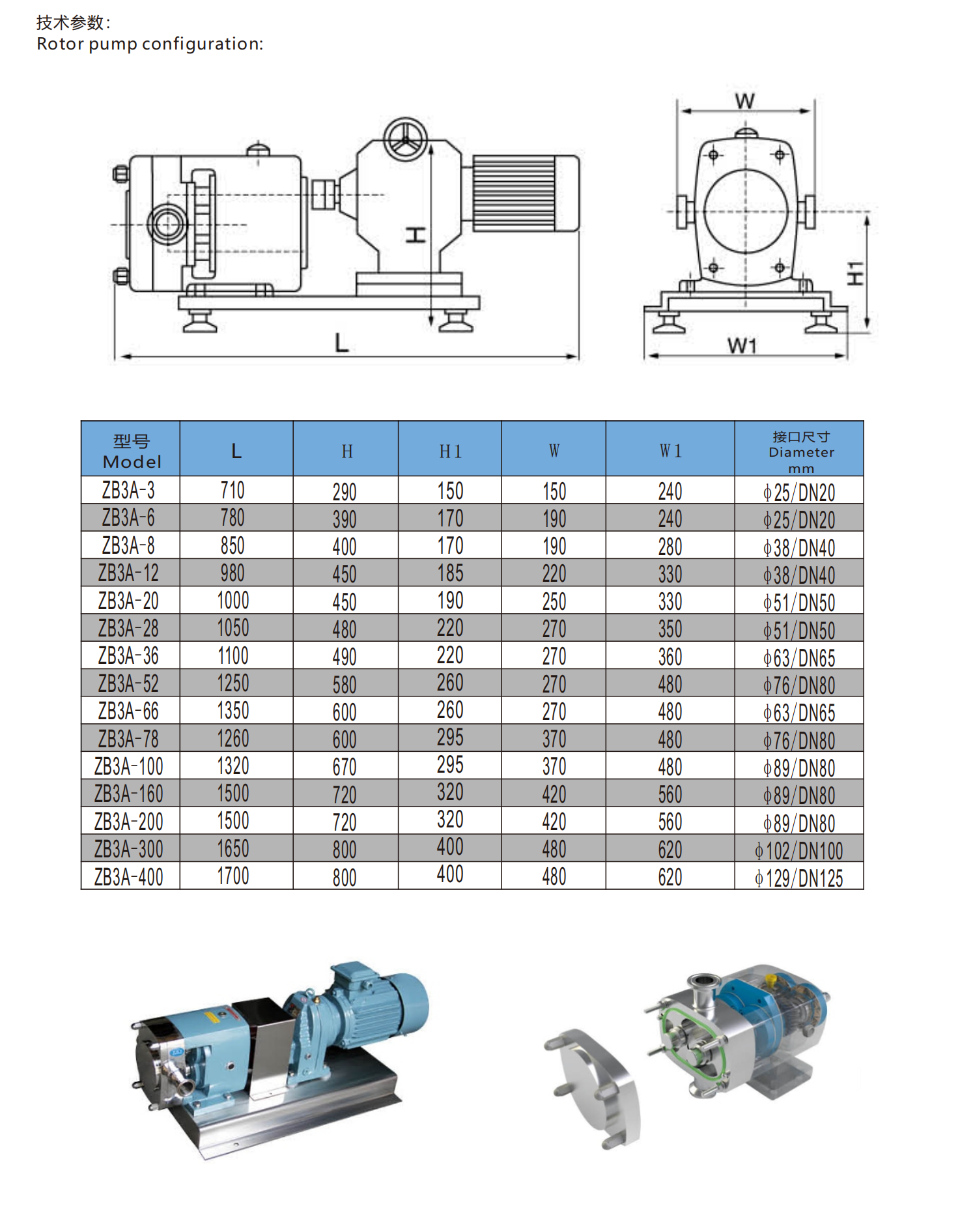

Stainless Steel Lobe Pump Specification Chart

Max. flow rate |

50m3/h

|

Max viscosity

|

100000Cps |

Power supply |

0.75kw to 22kw

|

Max. temperature | 120 °C |

Material |

SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

| Motor type | variable frequency motor, fixed speed motor |

Features

● Heat jacket as an optional choice for the media that is easy to solidification and freezing, such as chocolate

● Super clean and compact design in mechanical seal to keep hygiene

● There is no friction between rotors and pump body which ensures a long using life

● It is time-saving in fast assemble and disassemble.

● It has a characteristics of low speed with high output

● The conveying process is smooth and continuous

● Built-in safety valve can be require if any need.

● It can be equipped with trolley and control panel

Application

The rotary lobe pump is sanitary design which has wide use in application. It is not only used in high viscosity fluids, such as tomato paste, honey, chocolate, yogurt, but also can be used for the CIP&SIP system. It is widely applied in food, beverage, dairy, cosmetics,pharmaceuticals,chemical industry and others.