| Availability: | |

|---|---|

| Quantity: | |

JONENG

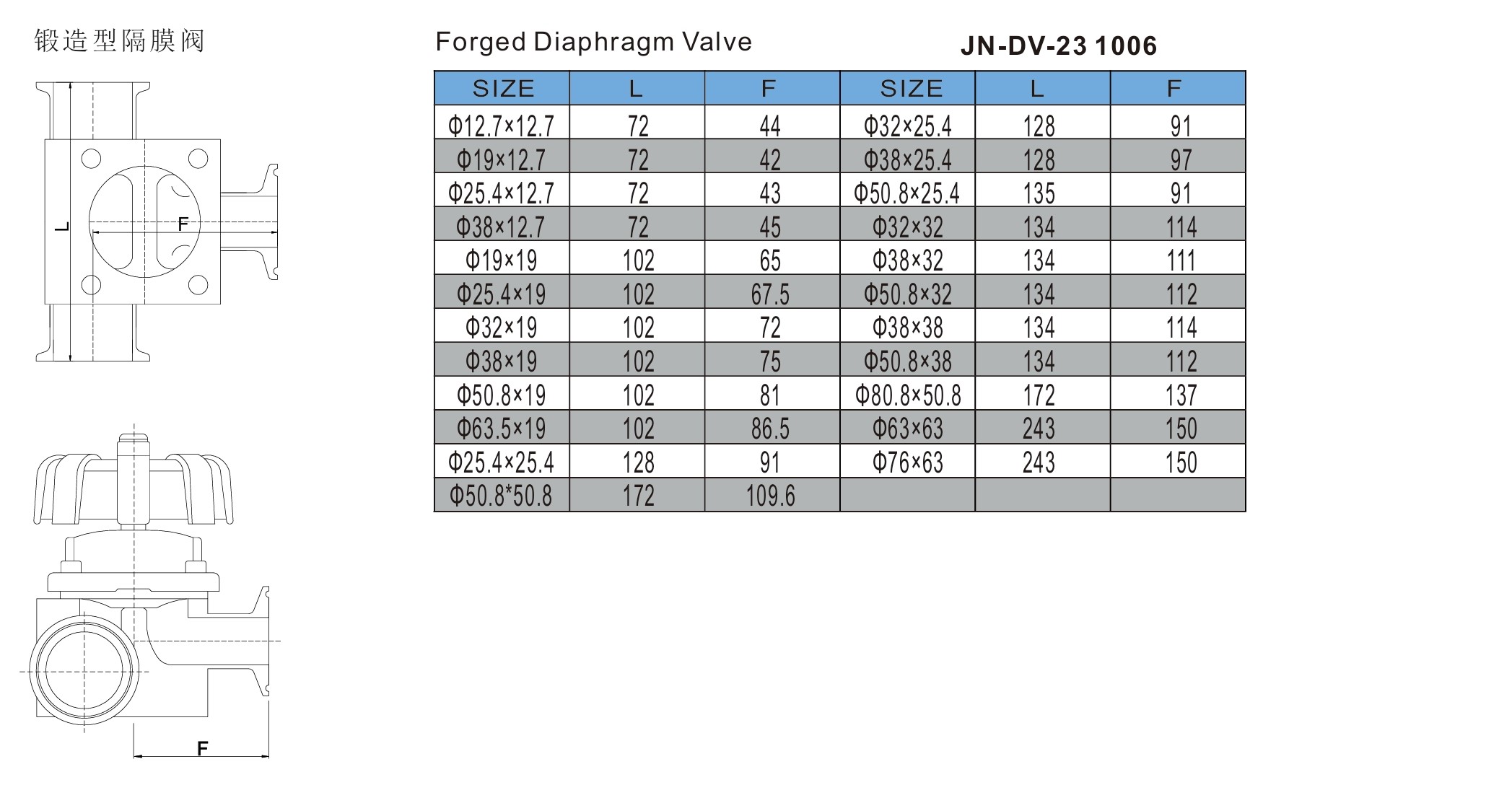

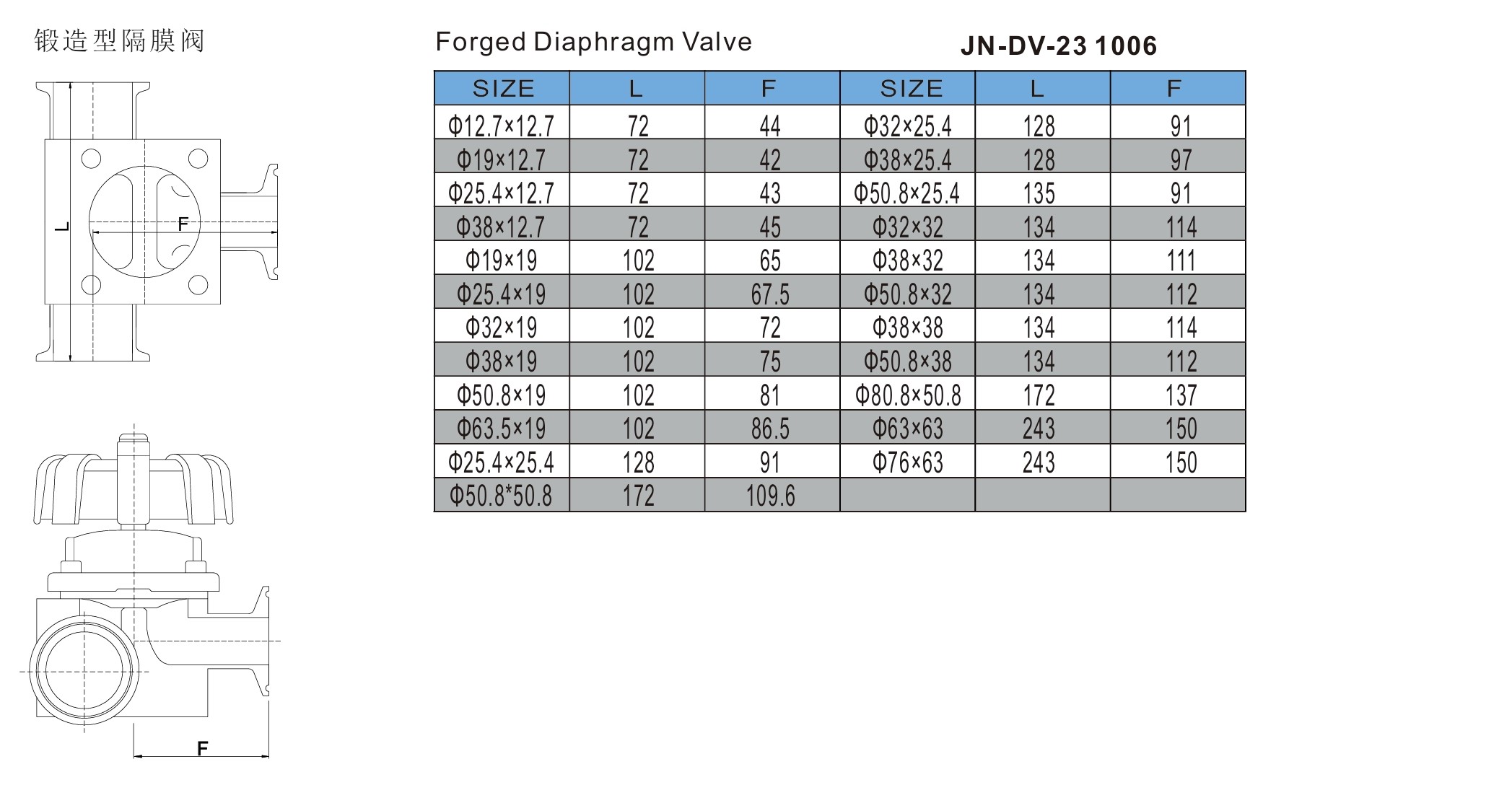

316L Sanitary Grade Multi-channel Biopharmaceutical Manual Diaphragm Valve

The 316L sanitary tee welded manual diaphragm valve is a high-performance fluid control component designed for hygienic applications. Crafted from premium 316L stainless steel, it boasts excellent corrosion resistance, anti-bacterial properties, and compliance with food-grade and pharmaceutical standards.

Working Principles

The 316L sanitary tee welded manual diaphragm valve operates via manual handwheel—turning it adjusts the stem to compress or loosen the diaphragm, controlling flow on/off or regulation—while its tee structure enables fluid diversion and the diaphragm isolates the stem from the medium to avoid contamination; crafted from 316L stainless steel, it ensures hygiene and corrosion resistance to meet food/pharmaceutical standards, with a welded design and zero dead zones preventing leakage and residue, supporting CIP/SIP cleaning, and offering precise control and low maintenance to enhance reliability in hygienic applications.

Stainless Steel Diaphragm Valve Specification Chart

| Parameter | Specification |

|---|---|

| Material | 316L Stainless Steel (AISI 316L, compliant with ASME BPE, DIN, etc.) |

| Valve Type | Sanitary Three-way Diaphragm Valve (T-type/three-way structure) |

| Diaphragm Material | EPDM / PTFE / Silicone / TFM (FDA & USP Class VI compliant) |

| Operation Method | Manual (with stainless steel handwheel) |

| Connection Type | Butt-weld |

| Flow Paths | Three-way flow path (dead-leg free design, supports CIP/SIP) |

| Surface Finish | Internal surface polished to Ra 0.4–0.8 μm (meets sanitary mirror polishing requirements) |

| Temperature Range | -20℃ to +150℃ (varies slightly depending on diaphragm material) |

| Pressure Rating | Maximum Working Pressure 10 bar (145 psi) |

| Standards | 3-A, FDA, CE PED, ASME BPE, DIN, SMS, ISO/IDF, etc. |

| Applications | Biopharmaceutical, food and beverage, dairy, brewing and other aseptic process fields |

Features

Material and Structural Features – Forged from 316L stainless steel, mirror-polished inner wall Ra < 0.4μm, seamless tee flow channel.

Sealing System Features– EPDM+PTFE double-layer diaphragm, PTFE in contact with the media, compliant with FDA standards.

Operational Design Features –Manual operation, visual position display, compact structure.

Hygiene Compatibility Features – Supports CIP/SIP, compliant with 3A and ASME standards. BPE Sanitary Standard

Flow Channel Functional Characteristics – T-junction for flow branching and merging; high-strength welding; compatible with DN15-DN100 specifications.

Application

Material and Structural Features – Corrosion and rust resistant, eliminates media residue, welded seal prevents leakage.

Sealing System Features– Resistant to acids, alkalis, and high temperatures, double seal, isolates the media from external contaminants.

Operational Design Features –No auxiliary energy required, intuitive operation, suitable for confined spaces.

Hygiene Compatibility Features – Convenient online cleaning and sterilization; compatible with most sanitary piping systems.

Flow Channel Functional Characteristics –No need for additional directional valves; stable high pressure; meets multiple flow rate requirements.

Working Principles

The 316L sanitary tee welded manual diaphragm valve operates via manual handwheel—turning it adjusts the stem to compress or loosen the diaphragm, controlling flow on/off or regulation—while its tee structure enables fluid diversion and the diaphragm isolates the stem from the medium to avoid contamination; crafted from 316L stainless steel, it ensures hygiene and corrosion resistance to meet food/pharmaceutical standards, with a welded design and zero dead zones preventing leakage and residue, supporting CIP/SIP cleaning, and offering precise control and low maintenance to enhance reliability in hygienic applications.

Feature and Specification

Stainless Steel Diaphragm Valve Specification Chart

| Parameter | Specification |

|---|---|

| Material | 316L Stainless Steel (AISI 316L, compliant with ASME BPE, DIN, etc.) |

| Valve Type | Sanitary Three-way Diaphragm Valve (T-type/three-way structure) |

| Diaphragm Material | EPDM / PTFE / Silicone / TFM (FDA & USP Class VI compliant) |

| Operation Method | Manual (with stainless steel handwheel) |

| Connection Type | Butt-weld |

| Flow Paths | Three-way flow path (dead-leg free design, supports CIP/SIP) |

| Surface Finish | Internal surface polished to Ra 0.4–0.8 μm (meets sanitary mirror polishing requirements) |

| Temperature Range | -20℃ to +150℃ (varies slightly depending on diaphragm material) |

| Pressure Rating | Maximum Working Pressure 10 bar (145 psi) |

| Standards | 3-A, FDA, CE PED, ASME BPE, DIN, SMS, ISO/IDF, etc. |

| Applications | Biopharmaceutical, food and beverage, dairy, brewing and other aseptic process fields |

Features

Material and Structural Features – Forged from 316L stainless steel, mirror-polished inner wall Ra < 0.4μm, seamless tee flow channel.

Sealing System Features– EPDM+PTFE double-layer diaphragm, PTFE in contact with the media, compliant with FDA standards.

Operational Design Features –Manual operation, visual position display, compact structure.

Hygiene Compatibility Features – Supports CIP/SIP, compliant with 3A and ASME standards. BPE Sanitary Standard

Flow Channel Functional Characteristics – T-junction for flow branching and merging; high-strength welding; compatible with DN15-DN100 specifications.

Application

Material and Structural Features – Corrosion and rust resistant, eliminates media residue, welded seal prevents leakage.

Sealing System Features– Resistant to acids, alkalis, and high temperatures, double seal, isolates the media from external contaminants.

Operational Design Features –No auxiliary energy required, intuitive operation, suitable for confined spaces.

Hygiene Compatibility Features – Convenient online cleaning and sterilization; compatible with most sanitary piping systems.

Flow Channel Functional Characteristics –No need for additional directional valves; stable high pressure; meets multiple flow rate requirements.