| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Hygienic Food Grade Welded Pipe Straight Sight Glass

The stainless steel sanitary welded pipe straight-through sight glass is designed to achieve real-time observation of the fluid in the pipeline to ensure that the quality and state of the flowing materials in the pipeline meet the production standards. It uses high-strength stainless steel and transparent materials, which can effectively resist high temperature and corrosion, and does not affect the hygiene requirements of the pipeline. The sight glass enables operators to check the flow, color, bubbles, impurities, etc. of the fluid at any time without disassembling the pipeline, thereby improving quality control in the production process, reducing pollution risks, and timely discovering problems and making adjustments to ensure the efficiency, accuracy and safety of the production process.

Working Principles

The working principle of the stainless steel sanitary welded pipe straight-through sight glass is as follows: Weld the sight glass to the straight section of the pipeline to ensure good sealing and stability. When the fluid flows in the pipeline, it passes through the transparent sight glass window. The operator can monitor the color, bubbles, impurities, etc. of the fluid in real time through the sight glass window to determine whether there is any abnormality. The operator adjusts the production process or performs maintenance in time based on the results of the sight glass monitoring to ensure the normal delivery of the pipeline fluid. If a lighting system is installed, the light source in the sight glass helps to clearly observe the fluid state in a low-light environment.

The options of the stainless steel sanitary welded pipe straight-through sight glass include:

Material: 304 stainless steel, 316L stainless steel.

Lighting: Whether it is equipped with a built-in LED lighting system.

Sight glass window type: single-layer glass, double-layer glass.

Cleaning function: whether it has an automatic cleaning function.

Connection method: welding, quick-install connection.

Size: Select a sight glass of appropriate size according to the diameter of the pipeline.

Pressure level: suitable for sight glasses with different working pressures.

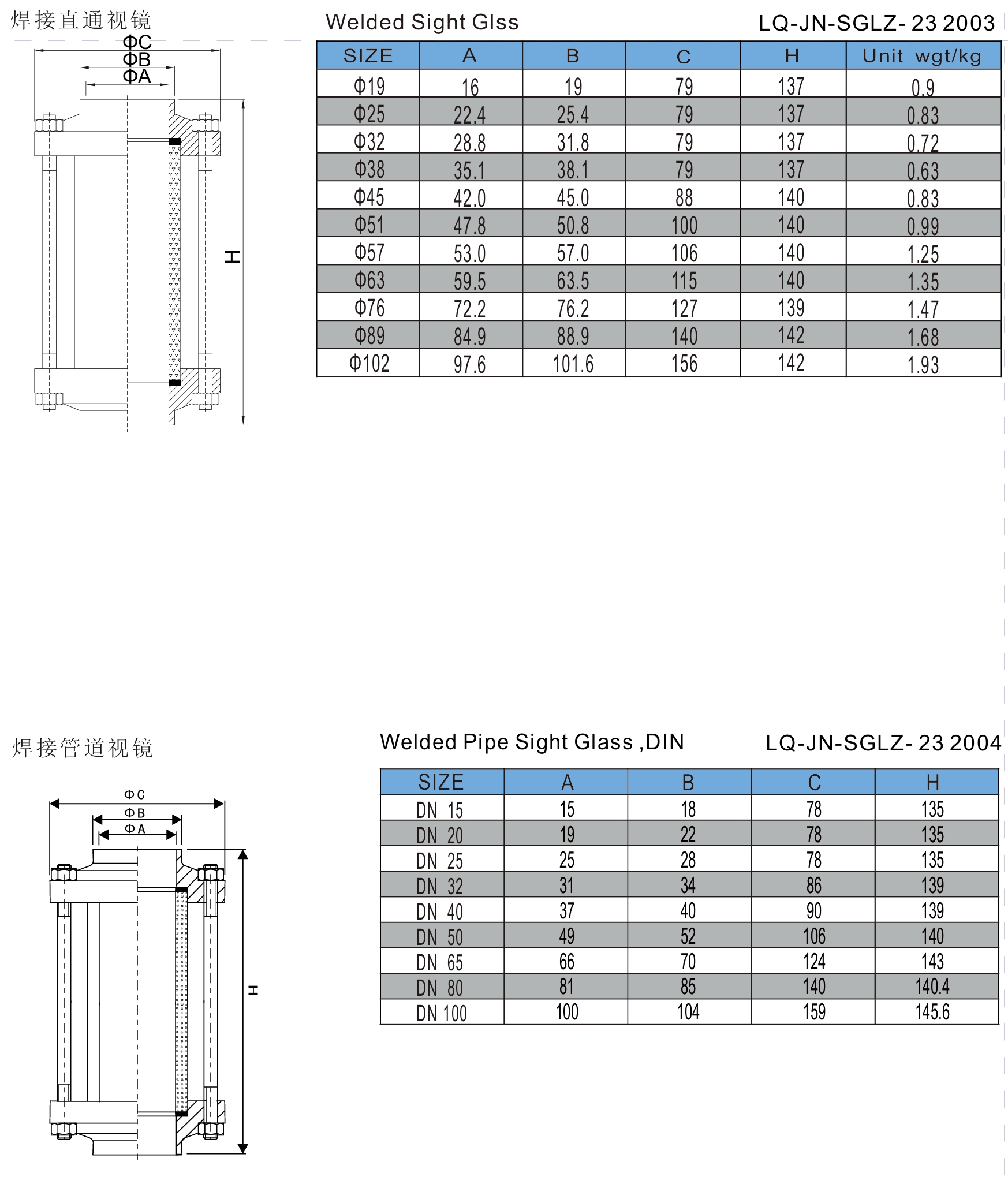

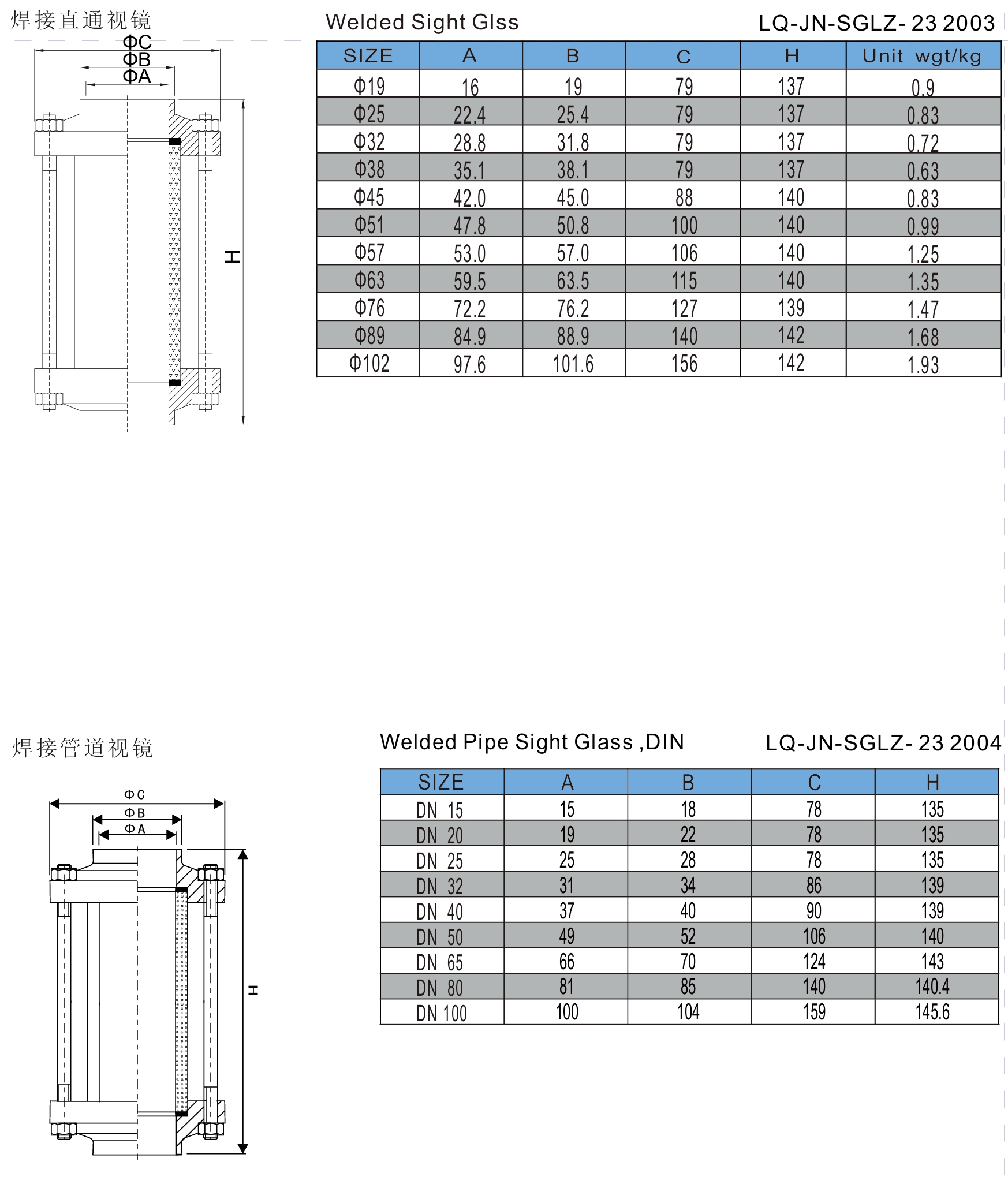

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary welded pipe straight-through sight glass adopts a double-layer glass design, and the middle interlayer increases the impact resistance and high pressure resistance.

● The stainless steel sanitary welded pipe straight-through sight glass adopts a design without external joints, avoiding the cleaning blind area of the traditional sight glass at the joint.

● The window of the stainless steel sanitary welded pipe straight-through sight glass adopts anti-ultraviolet material to effectively prevent the influence of ultraviolet rays on the fluid in the pipeline.

● The stainless steel sanitary welded pipe straight-through sight glass is equipped with a built-in automatic cleaning device, which is cleaned by pneumatic or hydraulic system.

● The stainless steel sanitary welded pipe straight-through sight glass has a built-in pressure sensor, which can monitor the pressure changes in the pipeline in real time.

● The stainless steel sanitary welded pipe straight-through sight glass adopts a special coating or optical enhancement design to make the observation window clearer and improve the visibility of the fluid.

Application

Stainless steel sanitary welded pipeline straight-through mirrors are widely used in the following industries: Food industry: used for flow monitoring of juice, dairy products and condiments. Pharmaceutical industry: monitor the flow state of liquid medicine to ensure pollution-free transportation. Chemical industry: used for fluid observation of corrosive or particulate substances. Beverage industry: ensure fluid quality control during beverage production. Cosmetic industry: used to monitor the flow and mixing state of cosmetic raw materials. Biological products industry: check the flow and quality of biological culture fluid. Water treatment industry: used to monitor the treatment process of sewage or wastewater.

Working Principles

The working principle of the stainless steel sanitary welded pipe straight-through sight glass is as follows: Weld the sight glass to the straight section of the pipeline to ensure good sealing and stability. When the fluid flows in the pipeline, it passes through the transparent sight glass window. The operator can monitor the color, bubbles, impurities, etc. of the fluid in real time through the sight glass window to determine whether there is any abnormality. The operator adjusts the production process or performs maintenance in time based on the results of the sight glass monitoring to ensure the normal delivery of the pipeline fluid. If a lighting system is installed, the light source in the sight glass helps to clearly observe the fluid state in a low-light environment.

The options of the stainless steel sanitary welded pipe straight-through sight glass include:

Material: 304 stainless steel, 316L stainless steel.

Lighting: Whether it is equipped with a built-in LED lighting system.

Sight glass window type: single-layer glass, double-layer glass.

Cleaning function: whether it has an automatic cleaning function.

Connection method: welding, quick-install connection.

Size: Select a sight glass of appropriate size according to the diameter of the pipeline.

Pressure level: suitable for sight glasses with different working pressures.

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary welded pipe straight-through sight glass adopts a double-layer glass design, and the middle interlayer increases the impact resistance and high pressure resistance.

● The stainless steel sanitary welded pipe straight-through sight glass adopts a design without external joints, avoiding the cleaning blind area of the traditional sight glass at the joint.

● The window of the stainless steel sanitary welded pipe straight-through sight glass adopts anti-ultraviolet material to effectively prevent the influence of ultraviolet rays on the fluid in the pipeline.

● The stainless steel sanitary welded pipe straight-through sight glass is equipped with a built-in automatic cleaning device, which is cleaned by pneumatic or hydraulic system.

● The stainless steel sanitary welded pipe straight-through sight glass has a built-in pressure sensor, which can monitor the pressure changes in the pipeline in real time.

● The stainless steel sanitary welded pipe straight-through sight glass adopts a special coating or optical enhancement design to make the observation window clearer and improve the visibility of the fluid.

Application

Stainless steel sanitary welded pipeline straight-through mirrors are widely used in the following industries: Food industry: used for flow monitoring of juice, dairy products and condiments. Pharmaceutical industry: monitor the flow state of liquid medicine to ensure pollution-free transportation. Chemical industry: used for fluid observation of corrosive or particulate substances. Beverage industry: ensure fluid quality control during beverage production. Cosmetic industry: used to monitor the flow and mixing state of cosmetic raw materials. Biological products industry: check the flow and quality of biological culture fluid. Water treatment industry: used to monitor the treatment process of sewage or wastewater.