| Availability: | |

|---|---|

| Quantity: | |

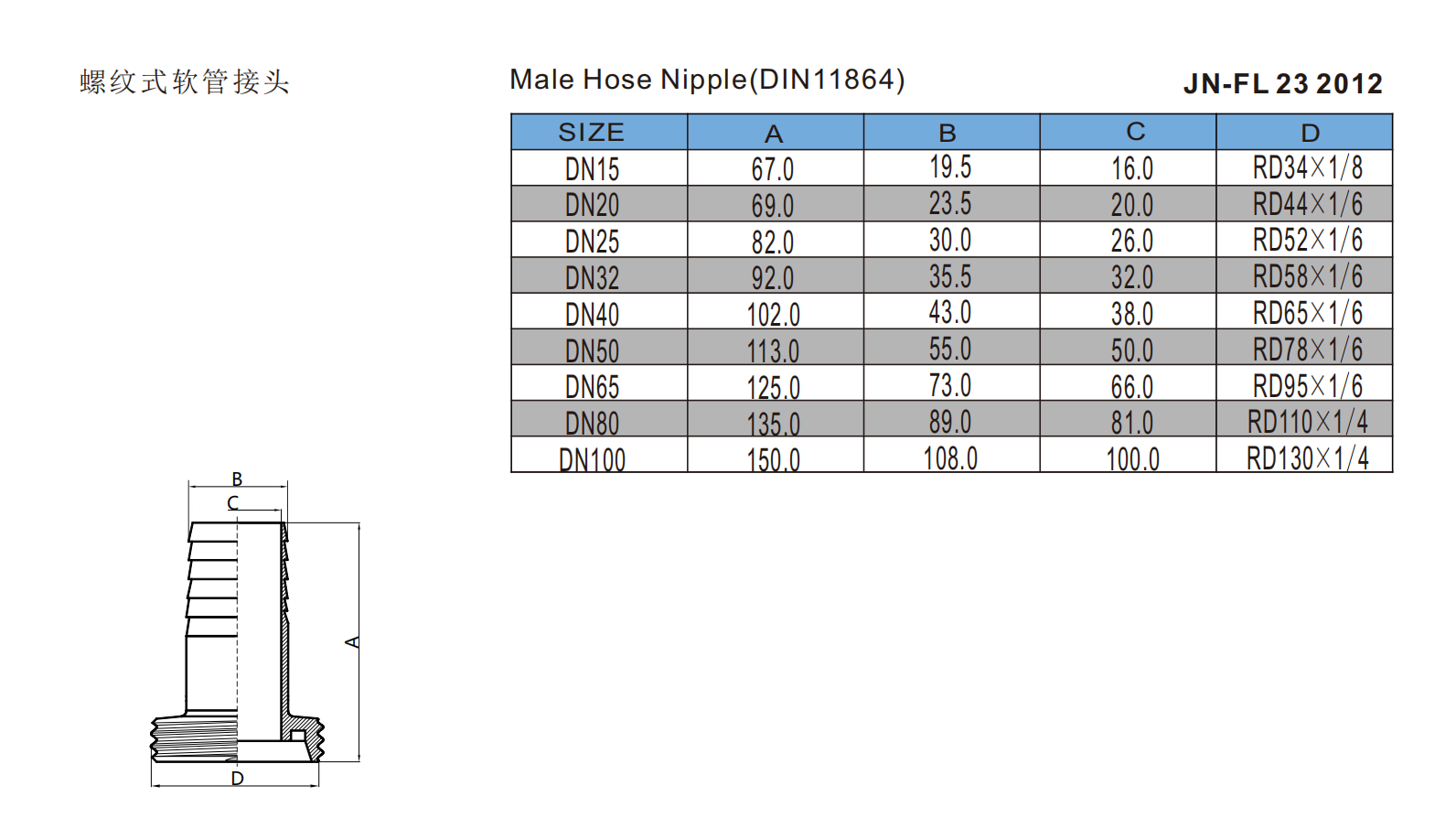

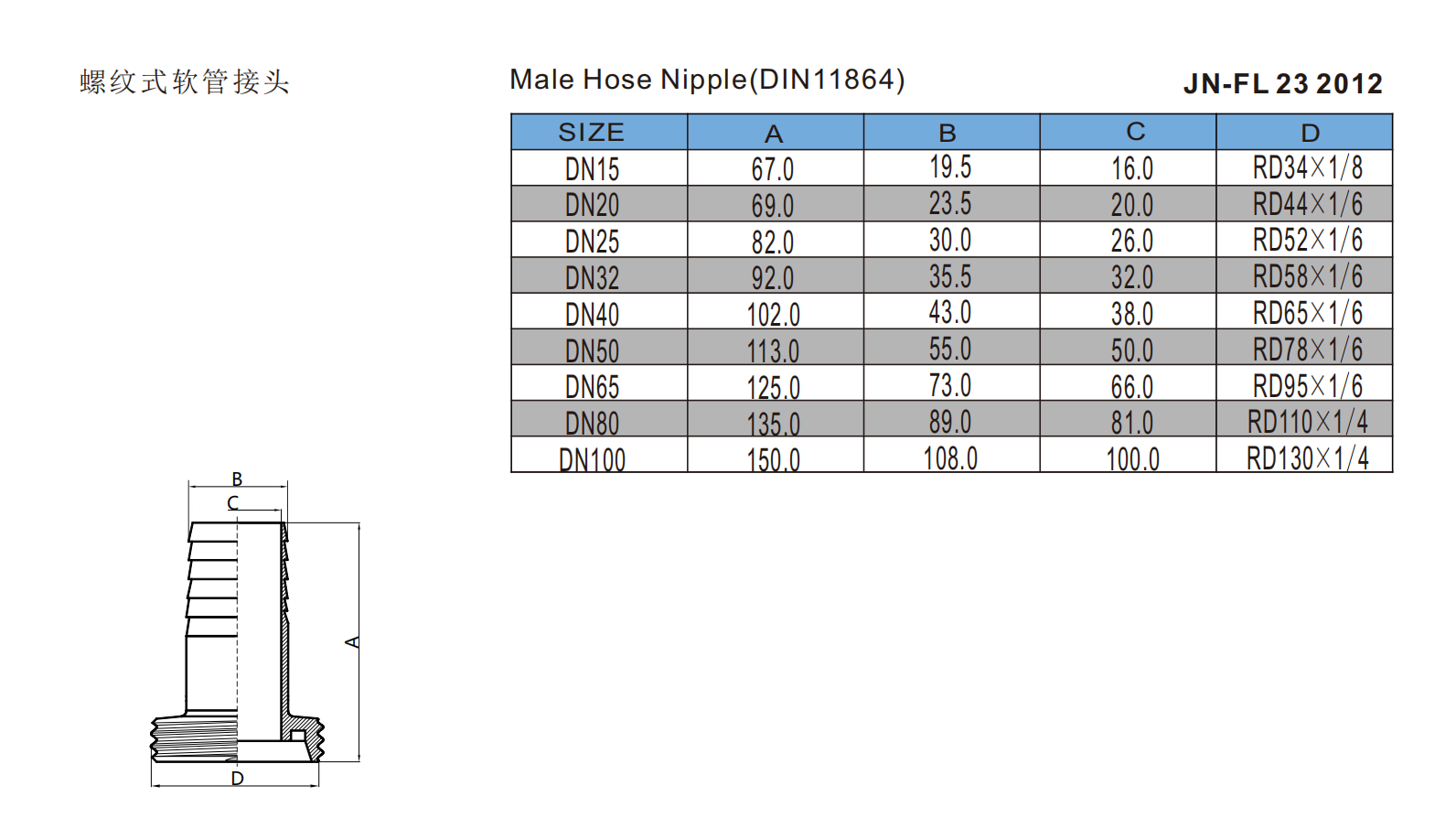

JN-FL 23 2012

JONENG

7307290000

Stainless Steel Food Grade FDA Threaded Hose Pipe Connector

The stainless steel sanitary threaded hose connector is designed to solve the safe and efficient connection of the hose with other equipment or pipelines in the pipeline system. Through the threaded connection method, the hose is firmly fixed to prevent loosening or leakage under high pressure, high temperature or vibration environment. In addition, it uses sanitary materials and precision technology to ensure that it meets the high requirements of hygiene, sterility and sealing in the food, pharmaceutical, chemical and other industries, avoid fluid contamination, cross infection or leakage, and improve the safety, stability and service life of the pipeline system.

Working principle

The working principle of the stainless steel sanitary threaded hose connector is based on threaded connection technology. Tighten one end of the connector to the interface of the pipe or equipment through the thread to ensure a firm connection. During operation, the connector provides mechanical locking through the threaded connection to ensure that the hose and the pipeline system will not loosen or fall off due to pressure fluctuations, vibrations, etc. The other end of the hose is connected to the equipment or pipeline, and the elasticity of the hose and the thread fixation of the connector ensure the stable transmission of the fluid. The use of stainless steel sanitary threaded hose connectors can provide a tight threaded connection to prevent fluid leakage and ensure the sealing of the system.

The options for stainless steel sanitary threaded hose connectors include:

Material: 304 stainless steel, 316L stainless steel.

Connection type: internal thread, external thread.

Sealing ring material: silicone, EPDM, fluororubber.

Size specifications: customized according to the specifications of the hose and pipeline.

Surface treatment: mirror polishing, pickling and passivation.

Specification Chart

| Material | SS304, SS316L | |

| Diameter | 1 "to 24" | |

| Length | 95mm to 265mm | |

| Standard | DIN, ISO, ASTM | |

| Max pressure | up to 10 bar | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Working temperatur | -15℃ to +160℃ | |

| End connections | Flanged, Threaded | |

| Gasket or seals | Viton, PTFEE | |

Features

● The stainless steel sanitary threaded hose connector adopts a self-locking thread design, which can effectively prevent loosening during the connection process.

● The stainless steel sanitary threaded hose connector adopts a double sealing ring design, which can maintain good sealing performance under different media and pressures.

● The threads of the stainless steel sanitary threaded hose connector are processed with anti-fatigue design, and there will be no cracks or deformation even in long-term repeated connection and disassembly.

● The inner wall of the stainless steel sanitary threaded hose connector is smooth and streamlined, which reduces the resistance of fluid flow and prevents eddy currents and material retention.

● The stainless steel sanitary threaded hose connector uses a sealing ring made of temperature-adaptive material, which can maintain good sealing at different temperatures.

● The stainless steel sanitary threaded hose connector adds anti-seismic reinforcement components in the connector design, which can withstand large vibrations and pressure fluctuations.

Application

Stainless steel sanitary threaded hose joints are widely used in the following industries: Food industry: ensure the hygiene and fluid safety of food production pipelines. Pharmaceutical industry: comply with GMP standards to prevent cross contamination. Chemical industry: suitable for the delivery of highly corrosive chemicals. Beverage industry: ensure the non-contamination of fluids during beverage production. Dairy industry: ensure the cleanliness and safety of the dairy production environment. Biopharmaceutical industry: provide precise control and fluid sealing functions. Cosmetics industry: ensure the sterility and sanitation of the cosmetics production line.

Working principle

The working principle of the stainless steel sanitary threaded hose connector is based on threaded connection technology. Tighten one end of the connector to the interface of the pipe or equipment through the thread to ensure a firm connection. During operation, the connector provides mechanical locking through the threaded connection to ensure that the hose and the pipeline system will not loosen or fall off due to pressure fluctuations, vibrations, etc. The other end of the hose is connected to the equipment or pipeline, and the elasticity of the hose and the thread fixation of the connector ensure the stable transmission of the fluid. The use of stainless steel sanitary threaded hose connectors can provide a tight threaded connection to prevent fluid leakage and ensure the sealing of the system.

The options for stainless steel sanitary threaded hose connectors include:

Material: 304 stainless steel, 316L stainless steel.

Connection type: internal thread, external thread.

Sealing ring material: silicone, EPDM, fluororubber.

Size specifications: customized according to the specifications of the hose and pipeline.

Surface treatment: mirror polishing, pickling and passivation.

Specification Chart

| Material | SS304, SS316L | |

| Diameter | 1 "to 24" | |

| Length | 95mm to 265mm | |

| Standard | DIN, ISO, ASTM | |

| Max pressure | up to 10 bar | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Working temperatur | -15℃ to +160℃ | |

| End connections | Flanged, Threaded | |

| Gasket or seals | Viton, PTFEE | |

Features

● The stainless steel sanitary threaded hose connector adopts a self-locking thread design, which can effectively prevent loosening during the connection process.

● The stainless steel sanitary threaded hose connector adopts a double sealing ring design, which can maintain good sealing performance under different media and pressures.

● The threads of the stainless steel sanitary threaded hose connector are processed with anti-fatigue design, and there will be no cracks or deformation even in long-term repeated connection and disassembly.

● The inner wall of the stainless steel sanitary threaded hose connector is smooth and streamlined, which reduces the resistance of fluid flow and prevents eddy currents and material retention.

● The stainless steel sanitary threaded hose connector uses a sealing ring made of temperature-adaptive material, which can maintain good sealing at different temperatures.

● The stainless steel sanitary threaded hose connector adds anti-seismic reinforcement components in the connector design, which can withstand large vibrations and pressure fluctuations.

Application

Stainless steel sanitary threaded hose joints are widely used in the following industries: Food industry: ensure the hygiene and fluid safety of food production pipelines. Pharmaceutical industry: comply with GMP standards to prevent cross contamination. Chemical industry: suitable for the delivery of highly corrosive chemicals. Beverage industry: ensure the non-contamination of fluids during beverage production. Dairy industry: ensure the cleanliness and safety of the dairy production environment. Biopharmaceutical industry: provide precise control and fluid sealing functions. Cosmetics industry: ensure the sterility and sanitation of the cosmetics production line.