| Availability: | |

|---|---|

| Quantity: | |

JONENG

STAINLESS STEEL Electric Actuator Concentric Rubber Seat Butterfly Valve

A Stainless Steel Clamped Hastelloy Pneumatic Wafer Butterfly Valve is a corrosion-resistant hygienic flow-control device designed for tight spaces and demanding media. It uses a pneumatic actuator to rotate a disc within a wafer-style body, providing rapid, reliable shutoff and smooth regulation in sanitary or chemically aggressive environments.

Working Principles

This 6-inch stainless steel PVC clamp-type solenoid butterfly valve uses a solenoid coil to control the rotation of the valve plate, thus opening and closing the pipeline medium. When the solenoid coil is energized, the magnetic force pushes the valve stem to rotate the butterfly plate, opening the valve and allowing the medium to flow smoothly. When the power is off, a spring or reset mechanism drives the butterfly plate to close, pressing the butterfly plate against the valve seat to form a seal and prevent medium leakage. The valve body is made of a combination of PVC and stainless steel, and the clamp connection allows for quick and easy installation and disassembly. It is suitable for automated control and remote operating systems of water treatment, beverage, food, and chemical liquid pipelines, and features a compact structure and corrosion resistance.

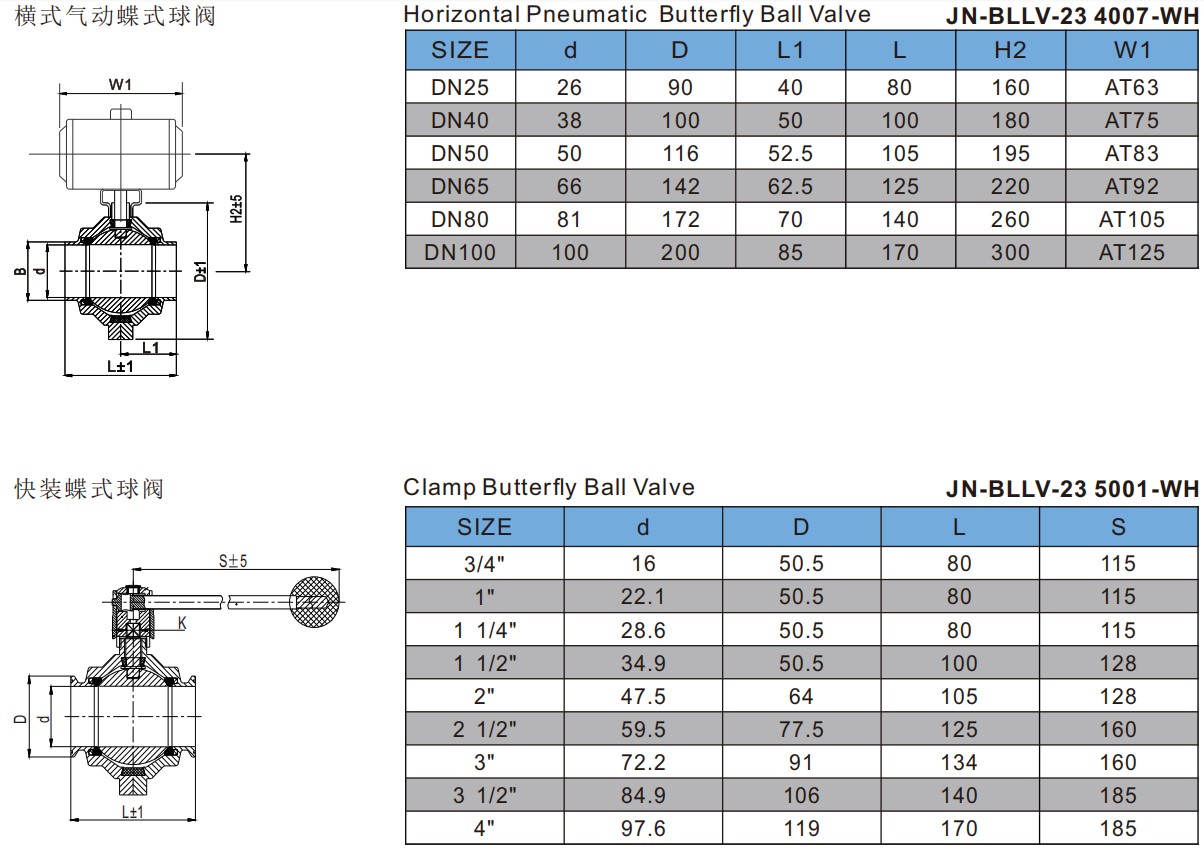

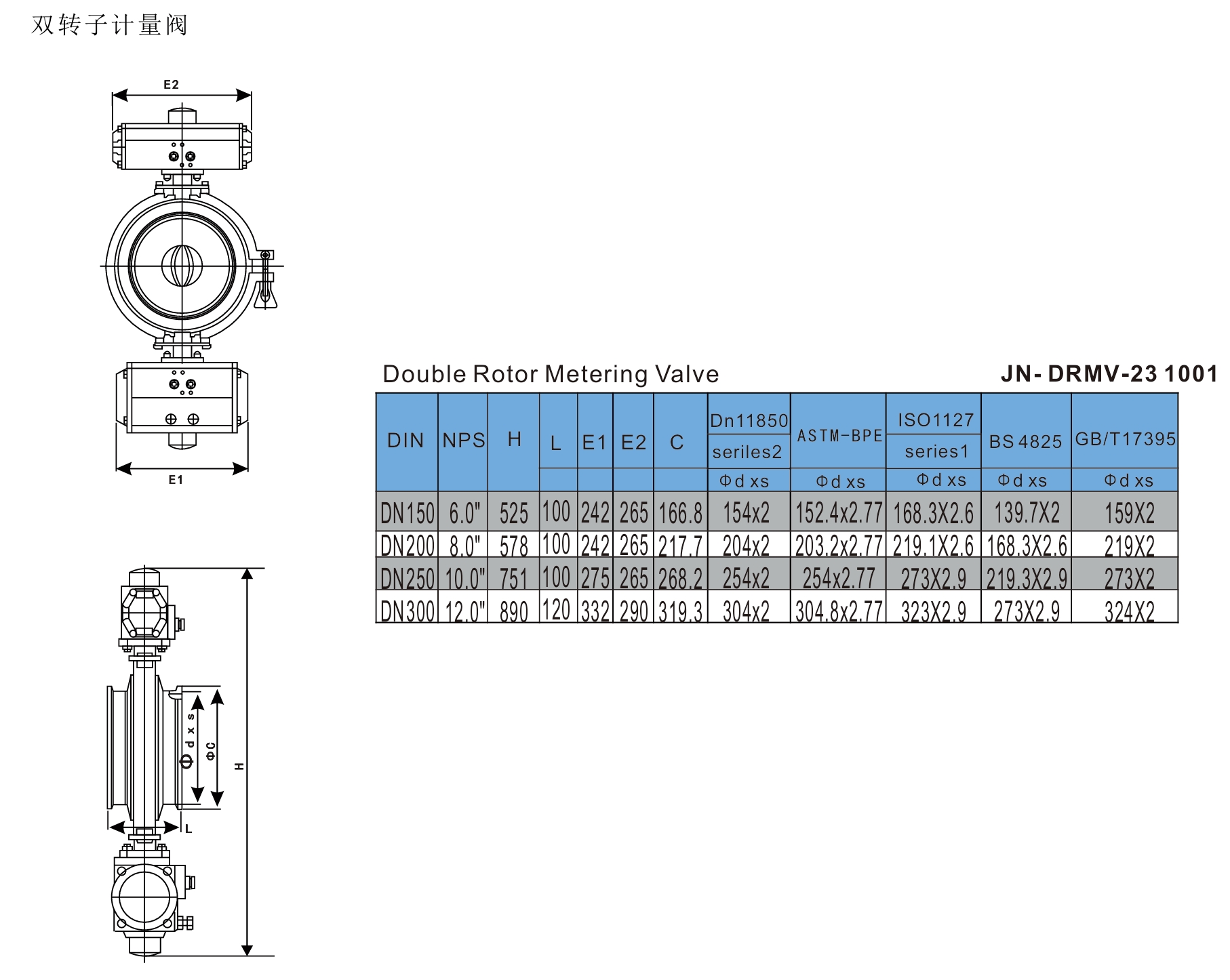

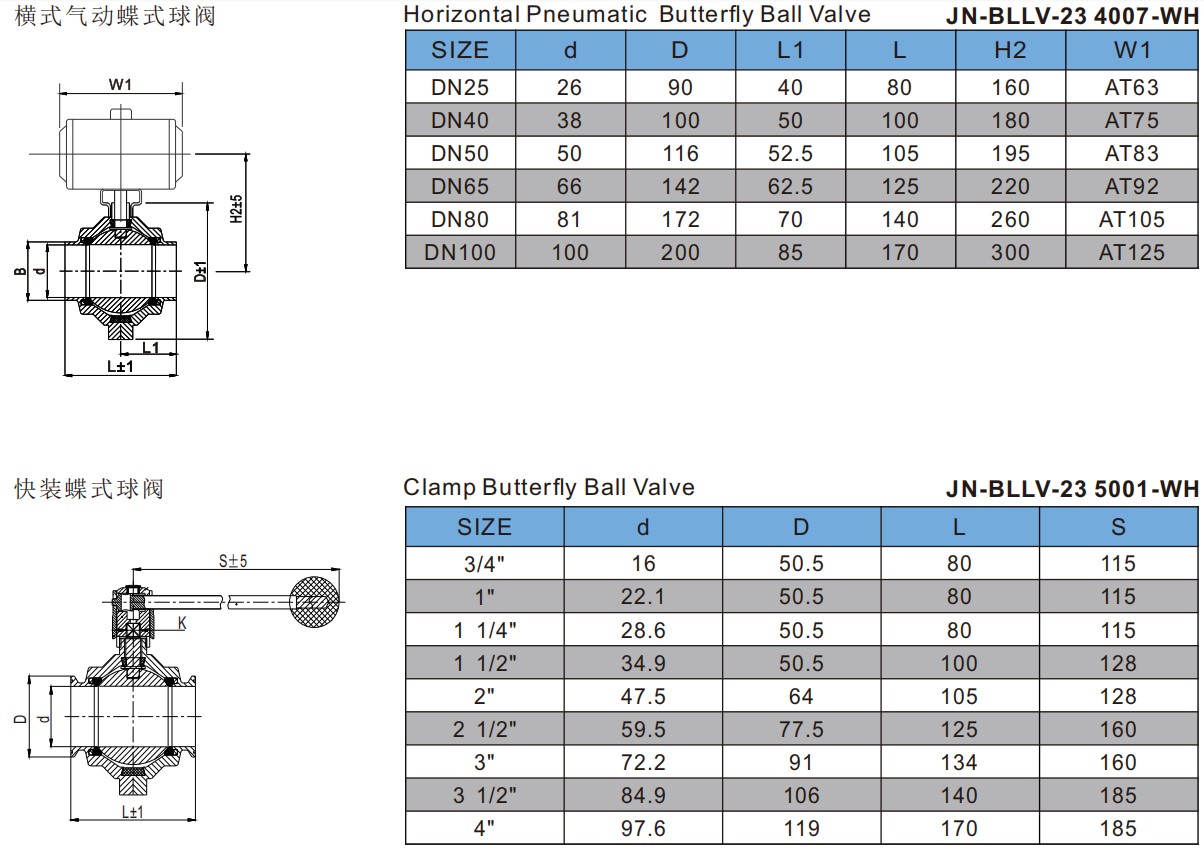

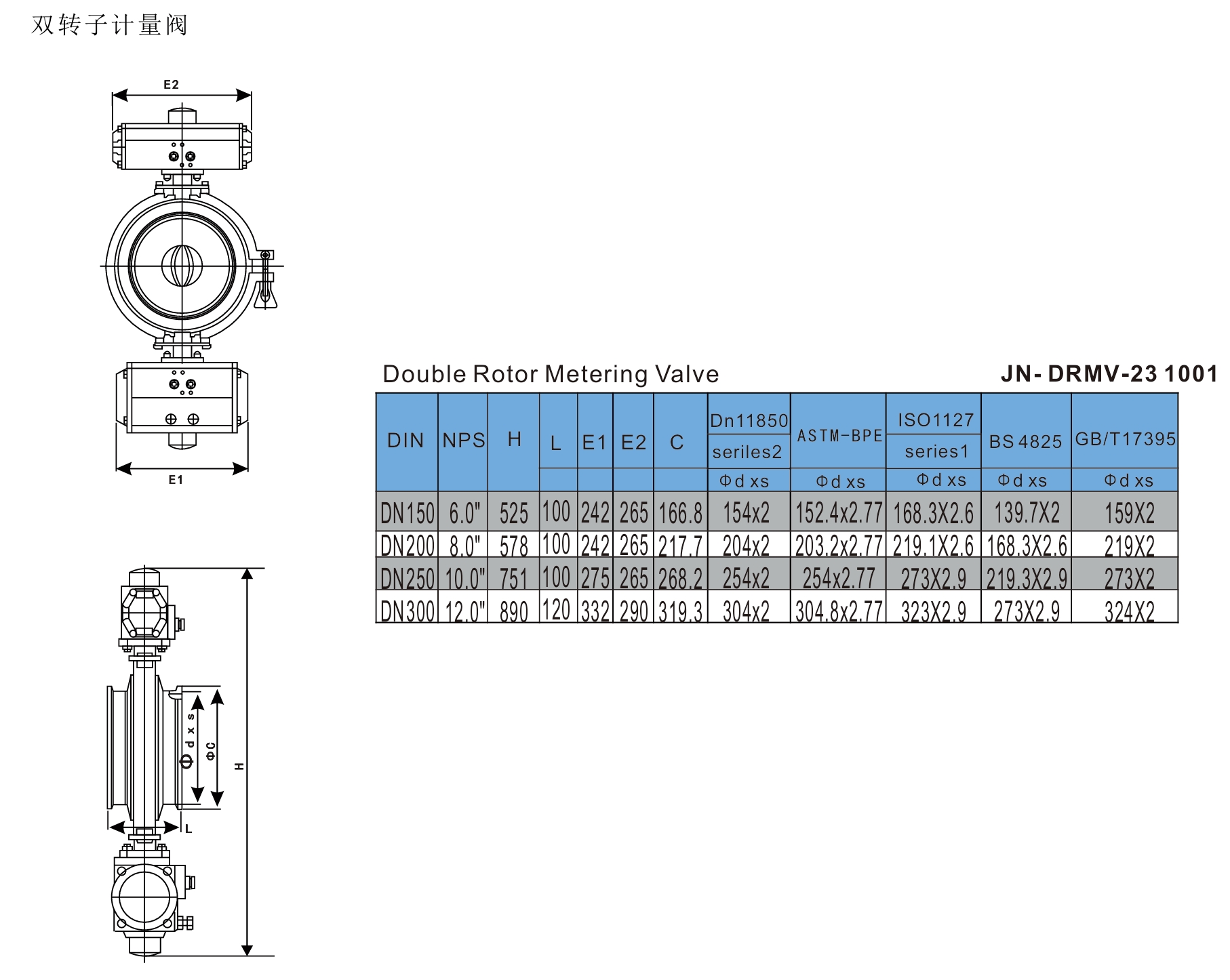

Stainless Steel Butterfly Valve Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Features

Made from high-quality stainless steel, providing excellent corrosion resistance and durability in industrial, chemical, and sanitary pipeline applications.

Concentric rubber seat ensures tight sealing and prevents leakage, maintaining stable performance under varying pressure and flow conditions.

Electric actuator allows automated operation, remote control, and integration with process control systems for precise valve management.

Compact and lightweight design simplifies installation in pipelines with limited space while ensuring reliable operation and easy maintenance.

Suitable for liquids, gases, and low-viscosity media, providing efficient flow control, energy saving, and long service life in diverse industrial systems

Application

Stainless steel 6-inch PVC clamp-type solenoid butterfly valves are widely used in water treatment, food processing, beverage bottling, and chemical pipeline systems. For example, in drinking water pipelines, they are used for automatic flow control; in food processing plants, they enable remote switching and precise flow control when transporting liquid raw materials, while ensuring system hygiene and corrosion resistance.

Working Principles

This 6-inch stainless steel PVC clamp-type solenoid butterfly valve uses a solenoid coil to control the rotation of the valve plate, thus opening and closing the pipeline medium. When the solenoid coil is energized, the magnetic force pushes the valve stem to rotate the butterfly plate, opening the valve and allowing the medium to flow smoothly. When the power is off, a spring or reset mechanism drives the butterfly plate to close, pressing the butterfly plate against the valve seat to form a seal and prevent medium leakage. The valve body is made of a combination of PVC and stainless steel, and the clamp connection allows for quick and easy installation and disassembly. It is suitable for automated control and remote operating systems of water treatment, beverage, food, and chemical liquid pipelines, and features a compact structure and corrosion resistance.

Feature and Specification

Stainless Steel Butterfly Valve Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Features

Made from high-quality stainless steel, providing excellent corrosion resistance and durability in industrial, chemical, and sanitary pipeline applications.

Concentric rubber seat ensures tight sealing and prevents leakage, maintaining stable performance under varying pressure and flow conditions.

Electric actuator allows automated operation, remote control, and integration with process control systems for precise valve management.

Compact and lightweight design simplifies installation in pipelines with limited space while ensuring reliable operation and easy maintenance.

Suitable for liquids, gases, and low-viscosity media, providing efficient flow control, energy saving, and long service life in diverse industrial systems

Application

The Stainless Steel Clamped Hastelloy Pneumatic Wafer Butterfly Valve is commonly used in industries requiring corrosion-resistant, automated flow control. Typical applications include chemical processing for acids and solvents, pharmaceutical and biotech production for sterile fluids, and food or beverage processing where compact, hygienic, and reliable valves are essential.