| Availability: | |

|---|---|

| Quantity: | |

JONENG

8421219990

Stainless Steel 3A Welding Pneumatic Bottom Diaphragm Control Valve

The stainless steel sanitary pneumatic tank bottom valve is designed to achieve efficient and automated liquid or material discharge control. Through pneumatic drive, the valve can be opened and closed quickly and accurately to ensure smooth discharge of fluids or materials during the production process, avoiding leakage or contamination. Its sanitary design meets the strict hygiene requirements of the food, beverage, pharmaceutical and other industries, is easy to clean and maintain, and ensures a pollution-free and high-standard sanitary environment. This valve can improve production efficiency, reduce manual operations, and improve the level of automation.

Working Principles

The working principle of the stainless steel sanitary pneumatic tank bottom valve is to control the opening and closing of the valve through a pneumatic actuator. The air source (compressed air) enters the actuator to drive the valve body or valve stem to open and close. When the pneumatic control signal is triggered, the valve opens or closes quickly. Its design ensures that the valve has good sealing when closed to avoid leakage or contamination. The use of stainless steel sanitary pneumatic tank bottom valves can ensure the cleanliness of the fluid during the discharge process, avoid contamination, and meet strict hygiene standards. In addition, pneumatic drive makes opening and closing fast and the operation precise, which helps to improve the smoothness and safety of the production line.

The options of stainless steel sanitary pneumatic tank bottom valves include:

Valve type: straight-through type, ball type, butterfly type, plug-in type, etc.

Connection method: threaded connection, flange connection.

Sealing material: different sanitary sealing materials, such as PTFE, Viton.

Drive mode: double-acting pneumatic or single-acting pneumatic.

Operating pressure: different working pressure ranges can be selected according to needs.

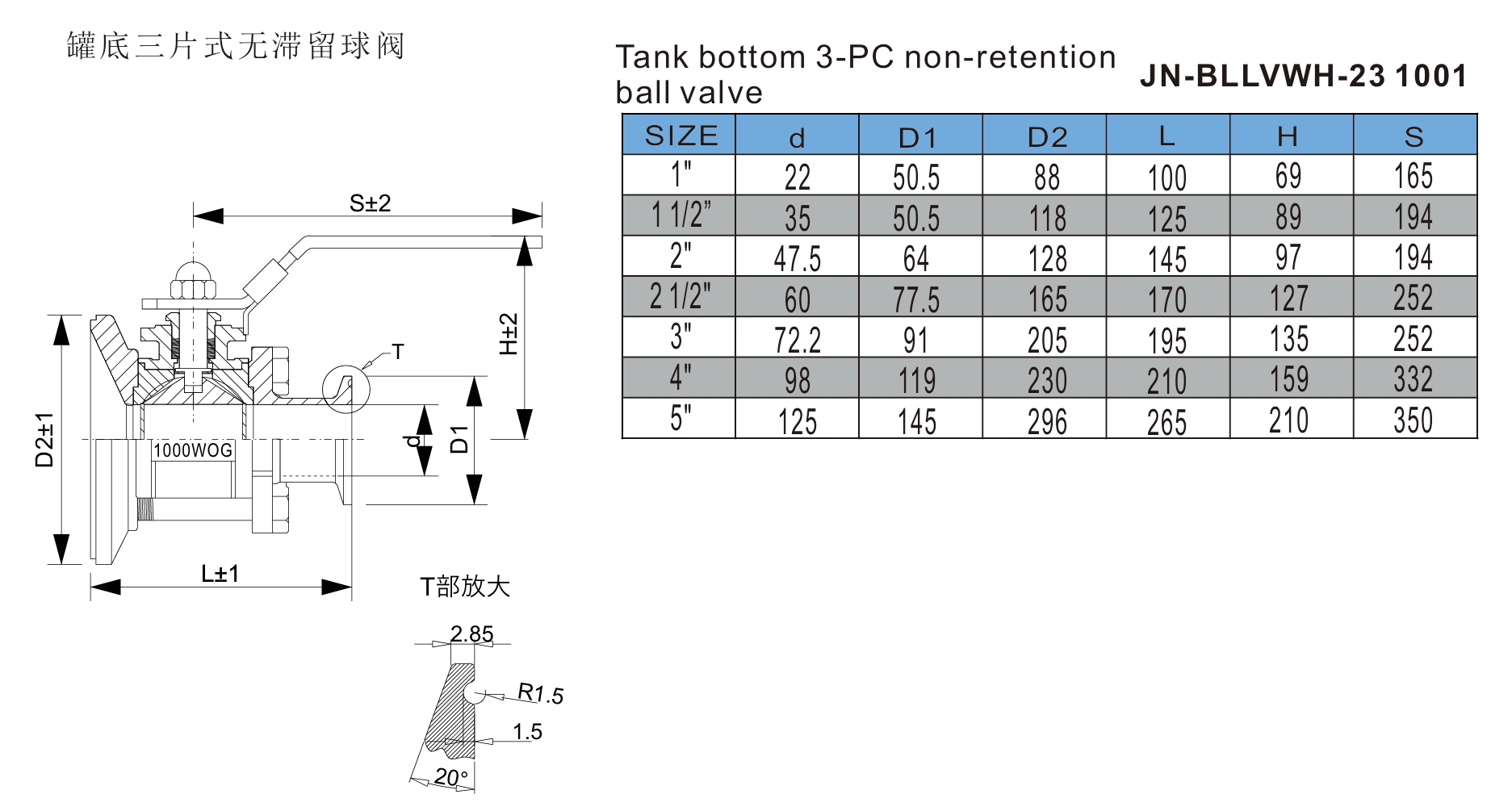

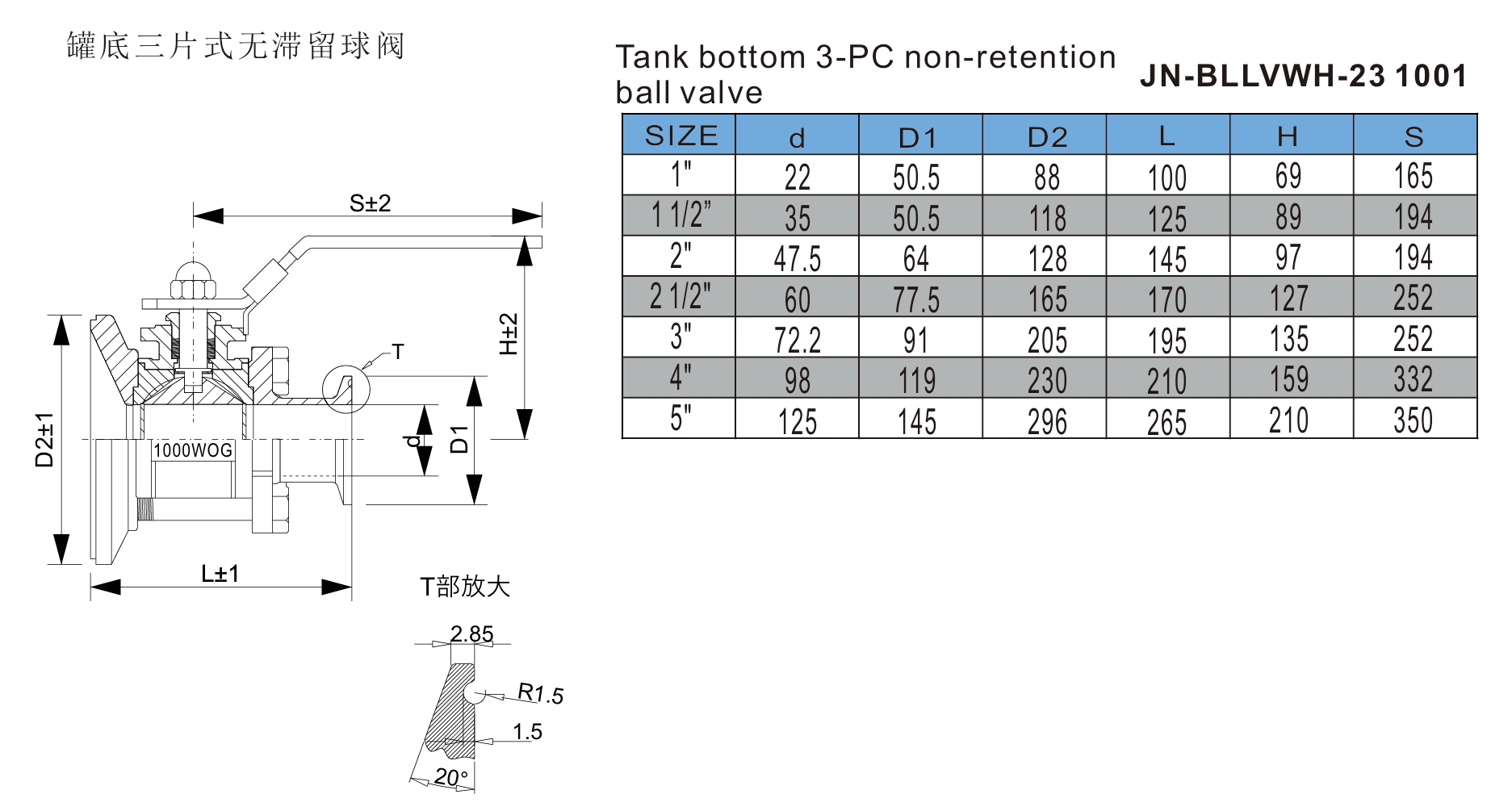

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● The stainless steel sanitary pneumatic tank bottom valve is equipped with a pneumatic actuator, which controls the opening and closing of the valve through air pressure to achieve automatic operation.

● The pneumatic control system of the stainless steel sanitary pneumatic tank bottom valve enables the valve to open and close quickly, reducing the retention of liquid during discharge.

● The stainless steel sanitary pneumatic tank bottom valve uses high-quality sealing materials such as PTFE to ensure no leakage and maintain the integrity of the system.

● There is no dead corner inside the valve body of the stainless steel sanitary pneumatic tank bottom valve to avoid material retention, ensure fluid hygiene, and meet food requirements.

● The stainless steel sanitary pneumatic tank bottom valve provides threaded and flange connections, which are convenient for connection with various pipeline systems and have strong adaptability.

● The stainless steel sanitary pneumatic tank bottom valve provides a double-acting pneumatic actuator to adapt to more complex control needs and provide more stable operation.

Application

Stainless steel sanitary pneumatic tank bottom valves are widely used in the following industry fields: Food and beverage industry, for automatic discharge and control of liquids or particles to ensure the hygiene and safety of fluids. Pharmaceutical industry, control the discharge of pharmaceutical raw materials and finished products to ensure compliance with strict hygiene standards. Chemical industry, handle chemical fluids and materials, prevent leakage, and ensure system safety. Dairy industry, control the discharge of raw materials and finished products in dairy production lines to ensure compliance with food grade requirements. Cosmetics industry, used to control the discharge of cosmetic raw materials and maintain high hygiene standards.

Working Principles

The working principle of the stainless steel sanitary pneumatic tank bottom valve is to control the opening and closing of the valve through a pneumatic actuator. The air source (compressed air) enters the actuator to drive the valve body or valve stem to open and close. When the pneumatic control signal is triggered, the valve opens or closes quickly. Its design ensures that the valve has good sealing when closed to avoid leakage or contamination. The use of stainless steel sanitary pneumatic tank bottom valves can ensure the cleanliness of the fluid during the discharge process, avoid contamination, and meet strict hygiene standards. In addition, pneumatic drive makes opening and closing fast and the operation precise, which helps to improve the smoothness and safety of the production line.

The options of stainless steel sanitary pneumatic tank bottom valves include:

Valve type: straight-through type, ball type, butterfly type, plug-in type, etc.

Connection method: threaded connection, flange connection.

Sealing material: different sanitary sealing materials, such as PTFE, Viton.

Drive mode: double-acting pneumatic or single-acting pneumatic.

Operating pressure: different working pressure ranges can be selected according to needs.

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● The stainless steel sanitary pneumatic tank bottom valve is equipped with a pneumatic actuator, which controls the opening and closing of the valve through air pressure to achieve automatic operation.

● The pneumatic control system of the stainless steel sanitary pneumatic tank bottom valve enables the valve to open and close quickly, reducing the retention of liquid during discharge.

● The stainless steel sanitary pneumatic tank bottom valve uses high-quality sealing materials such as PTFE to ensure no leakage and maintain the integrity of the system.

● There is no dead corner inside the valve body of the stainless steel sanitary pneumatic tank bottom valve to avoid material retention, ensure fluid hygiene, and meet food requirements.

● The stainless steel sanitary pneumatic tank bottom valve provides threaded and flange connections, which are convenient for connection with various pipeline systems and have strong adaptability.

● The stainless steel sanitary pneumatic tank bottom valve provides a double-acting pneumatic actuator to adapt to more complex control needs and provide more stable operation.

Application

Stainless steel sanitary pneumatic tank bottom valves are widely used in the following industry fields: Food and beverage industry, for automatic discharge and control of liquids or particles to ensure the hygiene and safety of fluids. Pharmaceutical industry, control the discharge of pharmaceutical raw materials and finished products to ensure compliance with strict hygiene standards. Chemical industry, handle chemical fluids and materials, prevent leakage, and ensure system safety. Dairy industry, control the discharge of raw materials and finished products in dairy production lines to ensure compliance with food grade requirements. Cosmetics industry, used to control the discharge of cosmetic raw materials and maintain high hygiene standards.