| Availability: | |

|---|---|

| Quantity: | |

JN 1021

JONENG

8481804090

Stainless Steel Ball Seat Pneumatic Flow Steering Valve

The purpose of the stainless steel pneumatic flow steering valve design is to achieve precise switching of the fluid direction to meet the needs of changes in the fluid flow path in the automation control system. Through pneumatic drive, the valve can quickly respond to operating signals, flexibly adjust the direction of fluid flow, and ensure efficiency and accuracy in the production process. Especially in highly hygienic environments, such as food processing and pharmaceutical industries, its corrosion resistance ensures the safety and hygiene of the product. At the same time, it can also cope with complex fluid media and changing working pressures, providing stable control. With this valve, the automation level of the entire pipeline system is improved, manual operations are reduced, and the automation and intelligence level of the production line is improved.

Working Principles

The working principle of the stainless steel pneumatic flow steering valve is based on the pneumatic drive principle, which controls the movement of the valve core through the action of air pressure to switch the flow direction of the fluid. First, the pneumatic signal is transmitted to the pneumatic actuator of the valve, and the piston or diaphragm in the actuator is pushed by the air source pressure. Under the action of the air source pressure, the piston or diaphragm pushes the valve core to move, changing the connection mode of the internal flow channel of the valve to achieve the purpose of switching the flow direction of the fluid. When the air source pressure stops acting, the valve core returns to the initial position and the fluid direction changes accordingly.

The options of the stainless steel pneumatic flow steering valve include:

Valve caliber: Select the appropriate caliber according to the pipeline size.

Drive mode: Single-acting or double-acting pneumatic actuator can be selected.

Connection mode: threaded connection, flange connection, etc.

Sealing material: Select different sealing materials according to the medium requirements.

Working pressure and temperature range: Select appropriate parameters according to the working conditions.

Automatic return function: Optional automatic reset or manual reset function.

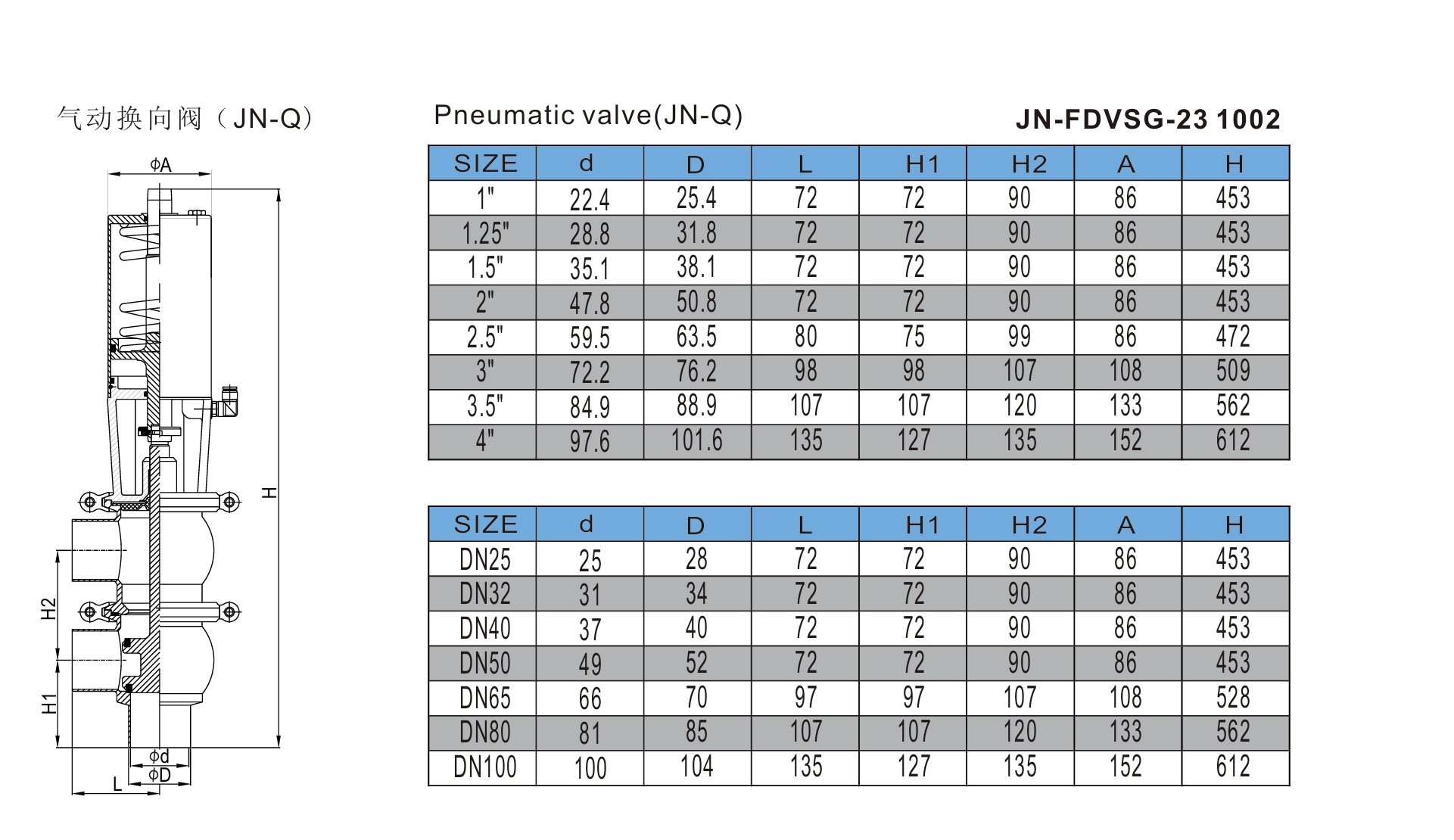

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel pneumatic flow steering valve is equipped with a precise pneumatic actuator, which can achieve flow direction switching between millimeters.

● The stainless steel pneumatic flow steering valve body and valve core surface adopt special anti-corrosion treatment technology to enhance resistance to chemical media such as acids and alkalis.

● The stainless steel pneumatic flow steering valve is equipped with a pressure regulating device, which can maintain the stable operation of the valve when the air source pressure fluctuates.

● The stainless steel pneumatic flow steering valve adopts low-friction materials and structures to reduce the contact area between the valve core and the valve body and reduce the friction coefficient.

● The internal design of the stainless steel pneumatic flow steering valve adopts an optimized pneumatic drive structure, which can complete the fluid flow direction switching in a short time.

● The stainless steel pneumatic flow steering valve adopts a multi-layer sealing design, which can maintain absolute sealing even in high-pressure environments.

Application

Stainless steel pneumatic flow steering valves are widely used in the following industries: Food and beverage industry: used for liquid flow control to ensure the hygiene and efficiency of the production process. Pharmaceutical industry: accurately adjust the direction of the fluid, meet hygiene standards, and ensure the safety of drug production. Chemical industry: control the flow direction of chemical fluids, strong corrosion resistance, and improve safety. Biopharmaceutical industry: used for fluid distribution in production lines to ensure accurate and efficient processes. Oil and gas industry: accurately adjust the flow of oil and gas to ensure stable and efficient operation of the system.

Working Principles

The sanitary reversing valve is operated by compressed air or manual handle. By controlling the relative position of the valve stem, the valve is opened or closed, or the flow direction is changed. When the sealing seat is pushed to the upper valve body, the valve is closed. When the piston is under the action of the spring, the piston pushes the sealing seat down and drives the valve stem to close the lower valve port.

For example, when processing the milk, the product medium with other media must be excluded. Double-acting valves can ensure this application, thus being able to install switchable flow paths for two incompatible media without risk of contamination even in the event of a leak. The seat also keeps the media separated from each other. So the flow diversion valve can be used for the fluid switching in the pipeline system without pollution or mixing.

Feature and Specification

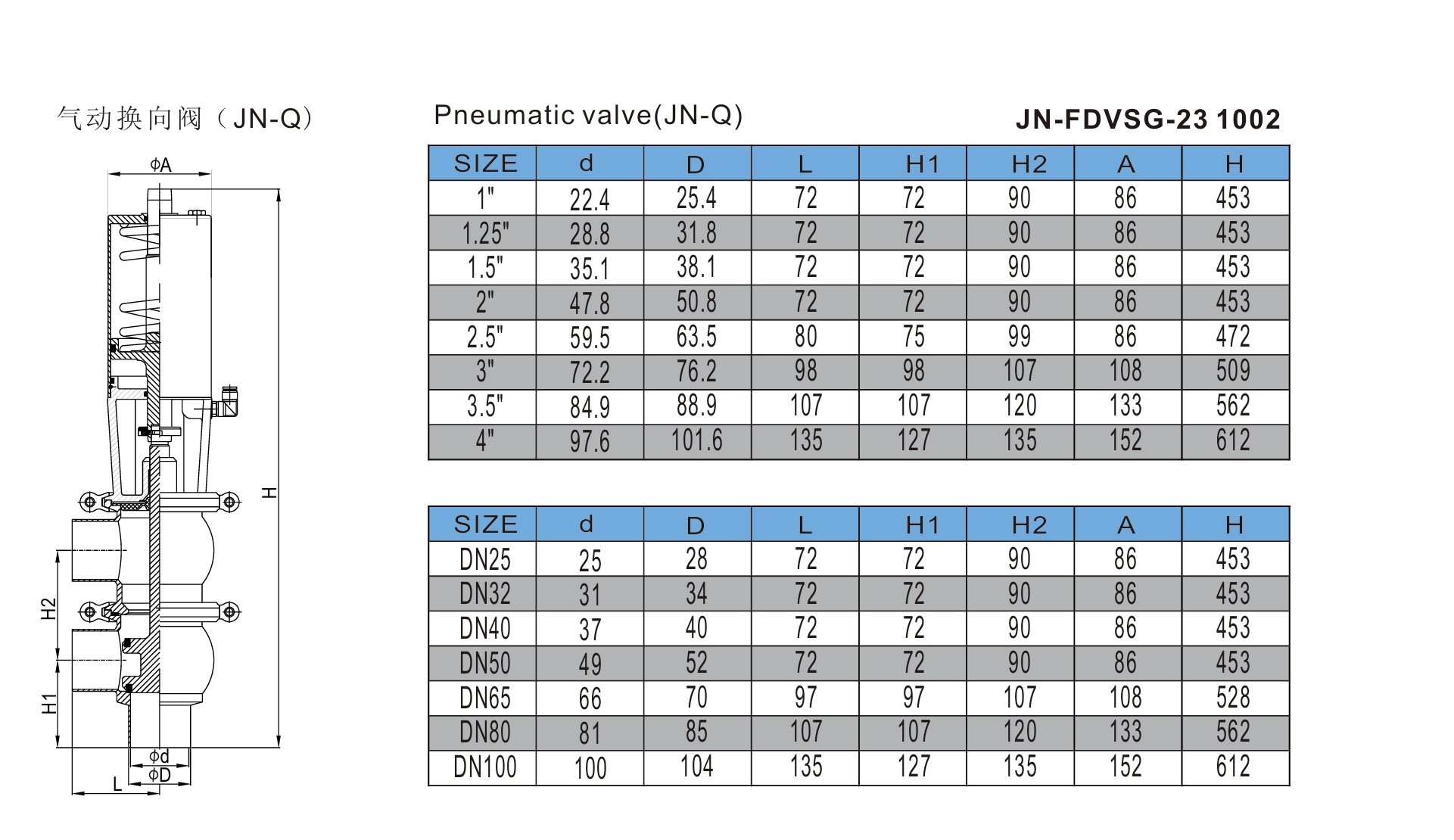

Stainless Steel Flow Diversion Valve Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● Dealing material softly

● High precise casting body

● Easy installation and dis-assemble by loosening the clamp

● 360 degree adjustable body

● Ultimate in easy cleaning to assure hygienic application

● Simple to change the structure and low maintenance cost

● Cost-efficient leakage protection

● Ultra-thick Spherical valve body assures ideal fluidity

● Available with various housing design and flexible orientations such as LL, LT, TL and TT types

Application

The flow diversion valves are major used to reach the medium to reverse or stop the flow direction, because of good seal ability and clean ability, they are extensively used to different industry areas, such as food, beverage, dairy, pharmacy, chemical and so on.