Stainless Steel Corrosion Resistant Flange Steam Plastic Head Pneumatic Angle Seat Valve

Stainless Steel Corrosion Resistant Flange Steam Plastic Head Pneumatic Angle Seat Valve is an automated valve designed for high-temperature steam control. Its plastic actuator head reduces weight and corrosion risk, while the flange connection ensures secure installation and reliable, hygienic operation in industrial systems.

Working Principles

The working principle of a Stainless Steel Corrosion Resistant Flange Steam Plastic Head Pneumatic Angle Seat Valve involves controlling the flow of high-temperature steam through an angled seat using a pneumatic actuator with a plastic head. When compressed air is applied, the piston inside the actuator moves, lifting the valve plug from the seat and allowing steam to flow smoothly through the valve. The angled seat minimizes flow resistance and ensures efficient discharge. Releasing or reversing the air pressure returns the piston, pressing the plug firmly against the seat to form a tight seal and prevent leakage. This design provides precise, automated control, lightweight operation, and reliable performance in corrosive and high-temperature environments.

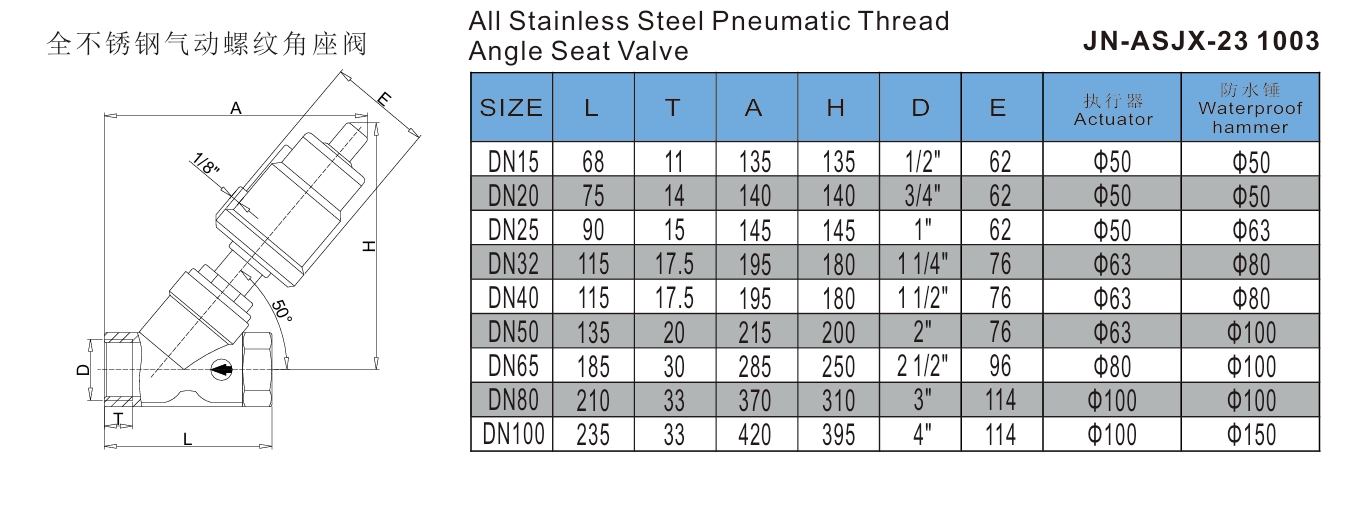

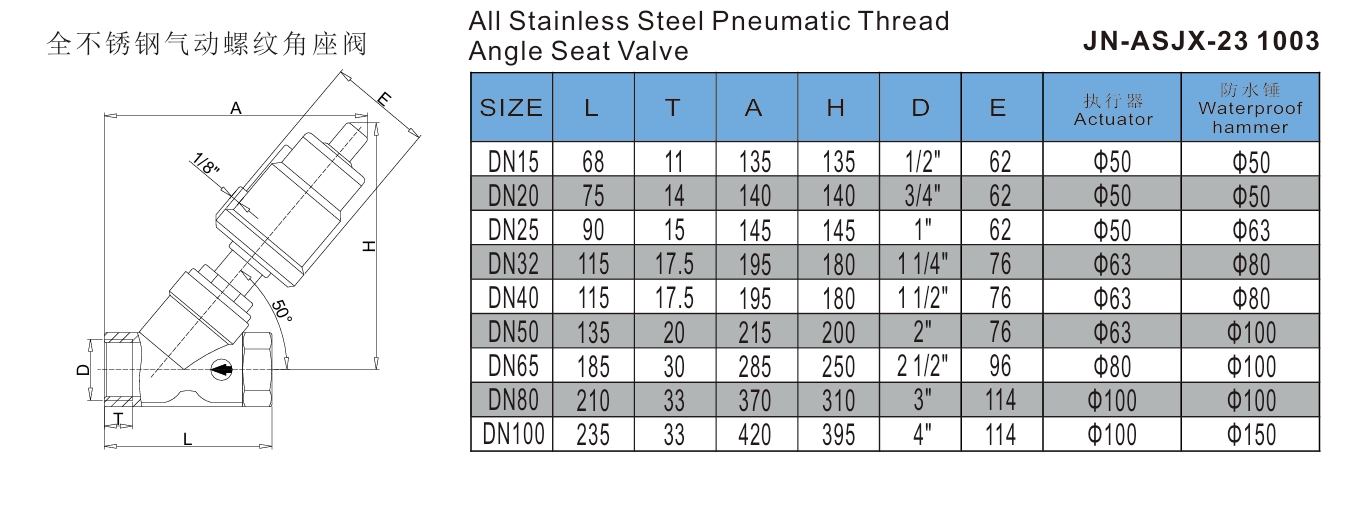

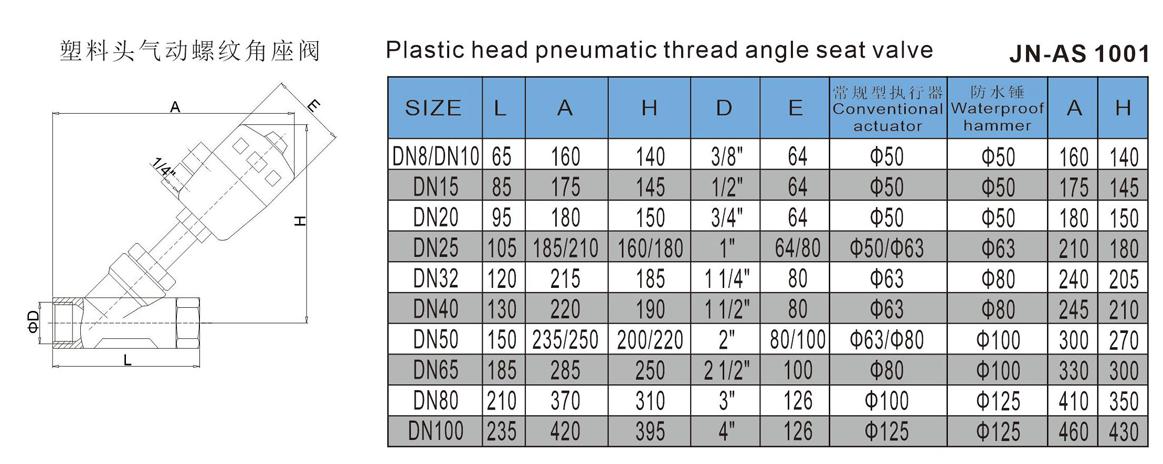

Stainless Steel Angle Seat Valve Specification Chart

Max Working Pressure | 1.6MPa |

Medium Temperature | -10℃~+180℃ |

Ambient Temperature | -10℃~+55℃ |

Body Materials | CF8M(SS316),CF8(SS304) |

Sealing Material | PTFE |

Operation | Normally Closed, Normally Open, Double-acting or Manually |

Connection End | Female, Weld,Clamp, Flange or on request |

Size Range | DN10-DN100 |

Surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Standards | DIN, SMS, ISO / IDF, BS / RJT, ASME / BPE. |

Control type | Single acting, double acting |

Features

Constructed from corrosion-resistant stainless steel, ensuring durability and reliable performance in high-temperature steam applications.

Plastic actuator head provides lightweight, corrosion-resistant operation, reducing wear and maintenance requirements.

Flange connection allows secure, stable installation and easy integration into industrial piping systems.

Angle seat design ensures smooth steam flow, minimizes pressure loss, and enhances overall process efficiency.

Pneumatic actuation delivers fast, precise, and automated valve control, supporting safe and efficient steam regulation.

Application

Stainless Steel Corrosion Resistant Flange Steam Plastic Head Pneumatic Angle Seat Valves are commonly used in food and beverage industries for steam-based sterilization and heating processes. They are also applied in pharmaceutical and chemical production, where precise, automated control of high-temperature steam is required. Their corrosion-resistant construction, flange connection, and lightweight plastic actuator head make them suitable for environments demanding reliable performance, safe operation, and easy integration into sanitary or industrial piping systems.