| Availability: | |

|---|---|

| Quantity: | |

The viewing mirror is also called the observer. Installation can be horizontal or vertical or any installation.

Uses: The sight glass can be used in chemical towers with high temperature, strong corrosiveness, easy poisoning, high danger, and easy crystallization to ensure its safe production.

Structure: The sight glass is mainly composed of the bottom plate of the sight glass, glass of the sight glass, valve components and so on.

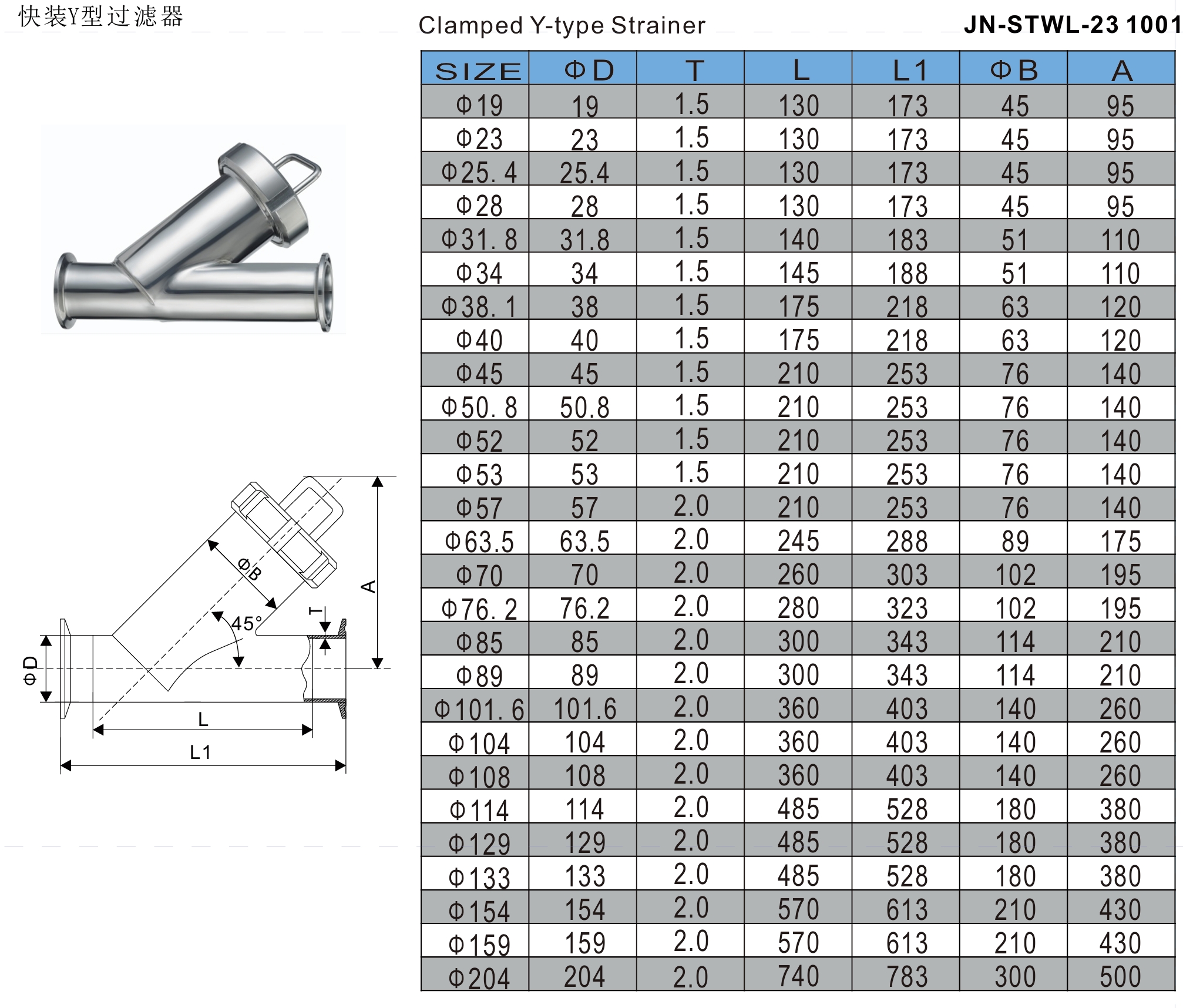

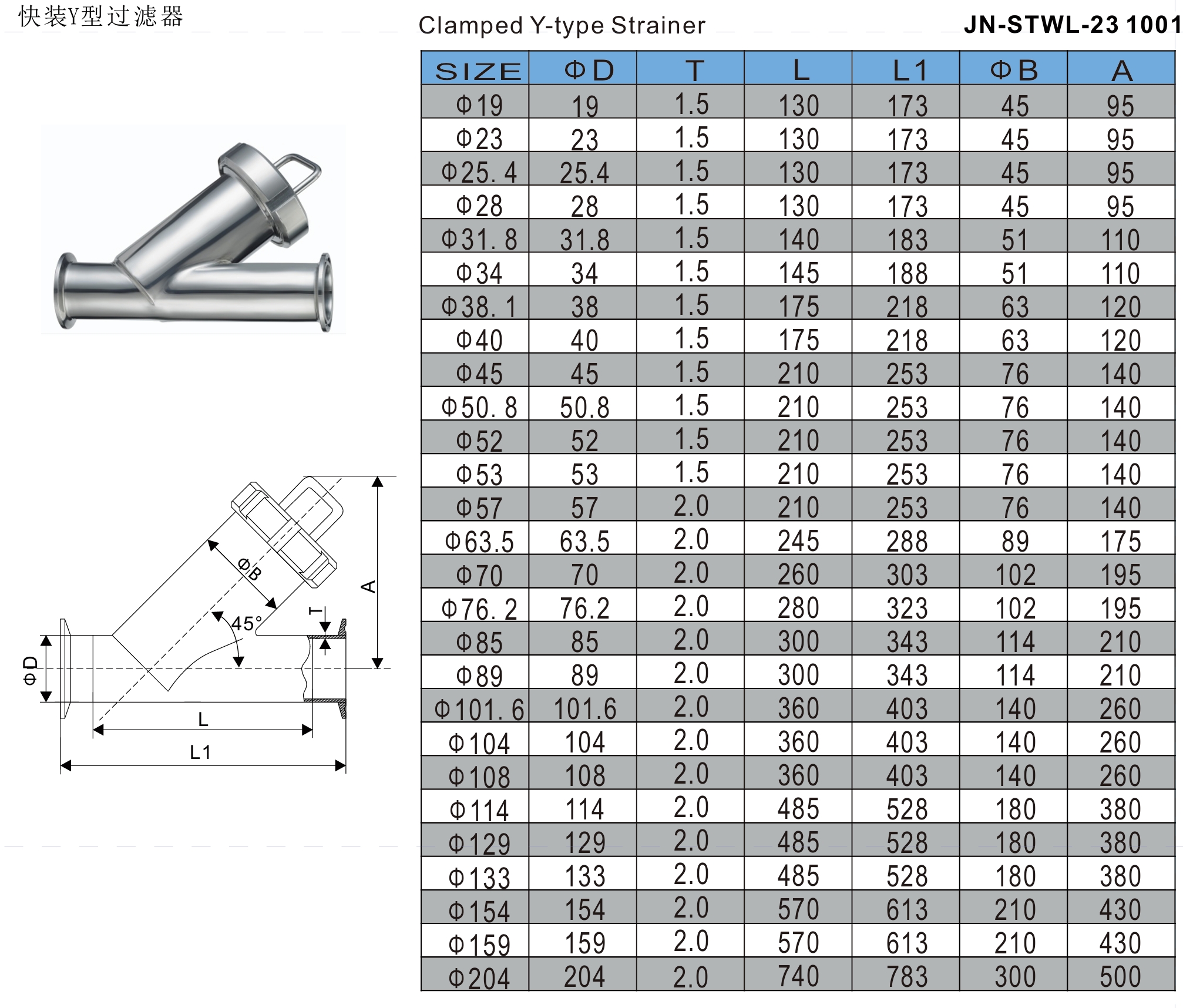

JN-STWL-23 1001

JONENG

8421219990

Stainless Steel Dairy Sanitary Water Air Clamped Y Type Filter Purufier Strainer JN-STWL-23 1001

The viewing mirror is also called the observer. Installation can be horizontal or vertical or any installation.

Uses: The sight glass can be used in chemical towers with high temperature, strong corrosiveness, easy poisoning, high danger, and easy crystallization to ensure its safe production.

Structure: The sight glass is mainly composed of the bottom plate of the sight glass, glass of the sight glass, valve components and so on.

Working Principles

The sight glass is convenient for observing the fluid process in the pipeline. In the middle and low pressure towers with sight glass, due to the high working temperature and strong corrosive liquid, it is easy to cause damage to the glass of the sight glass of the liquid level gauge. , it is easy to cause the glass of the sight glass to break. If it is not discovered in time, oil leakage will inevitably occur after driving. At this point the entire system must be stopped for hot washing and replacement. This not only brings difficulties to the long-term safe operation of the system, but also seriously affects production efficiency.

Stainless Steel Duplex Filter Specification Chart

Size | 1”-4” |

Material | AISI 316, AISI 304 |

Connection | Clamped, Welded, Threaded |

Gasket | Silicone, EPDM, Viton, PTFE |

Standard | 3A, DIN, SMS, ISO |

Mesh size | From 0.5mm to 2.0mm |

Screen | From 30 mesh to 300 mesh |

Internal Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

| External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

●Back flush available when cleaning.

● High rejection rate, high flow rate.

● Without any small particulates or impurities

● Strong filter power, small damage

● Made by CNC machine

Application

Sanitary Side-Entry Filters is used to eliminate the small particulates from compressors, pumps, meters and some other equipment. Main used in Beverage, Cosmetic, Dairy, Food, Meat or Poultry and Pharmaceutical Industries.

Working Principles

This works on a fairly simple principle, it filters and eliminates the pollutants by straining them through the mesh from liquid or gas while passing through the pipeline or tubing.

Feature and Specification

Stainless Steel Ln Line Filter Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

●Equipment protection, contaminant removal

●Product quality, improved system efficiency

●Customizability, health and safety

●Small pressure loss

●Good filtration

●Sealing ability

●Each cleaning

Application

This has various application in industries like water filtration and treatment plant, pharmaceutical and biotech, laboratory and research, chemical processing and others.

Stainless Steel Dairy Sanitary Water Air Clamped Y Type Filter Purufier Strainer JN-STWL-23 1001

The viewing mirror is also called the observer. Installation can be horizontal or vertical or any installation.

Uses: The sight glass can be used in chemical towers with high temperature, strong corrosiveness, easy poisoning, high danger, and easy crystallization to ensure its safe production.

Structure: The sight glass is mainly composed of the bottom plate of the sight glass, glass of the sight glass, valve components and so on.

Working Principles

The sight glass is convenient for observing the fluid process in the pipeline. In the middle and low pressure towers with sight glass, due to the high working temperature and strong corrosive liquid, it is easy to cause damage to the glass of the sight glass of the liquid level gauge. , it is easy to cause the glass of the sight glass to break. If it is not discovered in time, oil leakage will inevitably occur after driving. At this point the entire system must be stopped for hot washing and replacement. This not only brings difficulties to the long-term safe operation of the system, but also seriously affects production efficiency.

Stainless Steel Duplex Filter Specification Chart

Size | 1”-4” |

Material | AISI 316, AISI 304 |

Connection | Clamped, Welded, Threaded |

Gasket | Silicone, EPDM, Viton, PTFE |

Standard | 3A, DIN, SMS, ISO |

Mesh size | From 0.5mm to 2.0mm |

Screen | From 30 mesh to 300 mesh |

Internal Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

| External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

●Back flush available when cleaning.

● High rejection rate, high flow rate.

● Without any small particulates or impurities

● Strong filter power, small damage

● Made by CNC machine

Application

Sanitary Side-Entry Filters is used to eliminate the small particulates from compressors, pumps, meters and some other equipment. Main used in Beverage, Cosmetic, Dairy, Food, Meat or Poultry and Pharmaceutical Industries.

Working Principles

This works on a fairly simple principle, it filters and eliminates the pollutants by straining them through the mesh from liquid or gas while passing through the pipeline or tubing.

Feature and Specification

Stainless Steel Ln Line Filter Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

●Equipment protection, contaminant removal

●Product quality, improved system efficiency

●Customizability, health and safety

●Small pressure loss

●Good filtration

●Sealing ability

●Each cleaning

Application

This has various application in industries like water filtration and treatment plant, pharmaceutical and biotech, laboratory and research, chemical processing and others.