| Availability: | |

|---|---|

| Quantity: | |

JONENG

8421219990

Stainless Steel EHEDG Welding Pneumatic Bottom Diaphragm Control Valve

The stainless steel sanitary pneumatic tank bottom valve is designed to provide an efficient and automated solution for liquid or powder discharge, especially for industries that require strict sanitary conditions. It uses a pneumatic control system to achieve fast and precise switching operations, avoiding inconsistencies and potential contamination caused by manual operation. Through the compact design and the corrosion resistance of stainless steel, this valve can work stably under high pressure, low temperature and corrosive environments, reducing the risks caused by manual operation or equipment failure during production. Its automation features also improve production efficiency, precision and operational safety, meeting the high standards of hygiene and fluid control requirements of the food, pharmaceutical and other industries.

Working Principles

The working principle of the stainless steel sanitary pneumatic tank bottom valve is based on the pneumatic actuator to control the opening and closing of the valve. When the air source is input to the pneumatic actuator through the control system, the piston or diaphragm in the actuator is acted upon by air pressure, driving the sealing elements (such as the ball, valve plate or valve seat) inside the valve body to move. When the valve is open, the fluid is discharged from the bottom of the tank through the valve; when the valve is closed, the sealing element is in close contact with the valve seat to prevent fluid leakage. Using stainless steel sanitary pneumatic tank bottom valves can improve hygiene standards, automation levels and production efficiency.

The options for stainless steel sanitary pneumatic tank bottom valves include:

Valve body material: 304, 316L stainless steel.

Sealing materials: silicone, fluororubber, EPDM, etc.

Drive mode: single-acting or double-acting pneumatic actuator.

Connection mode: flange connection, threaded connection.

Control mode: manual, automatic control or remote control.

Valve types: ball, butterfly, slide valve, etc.

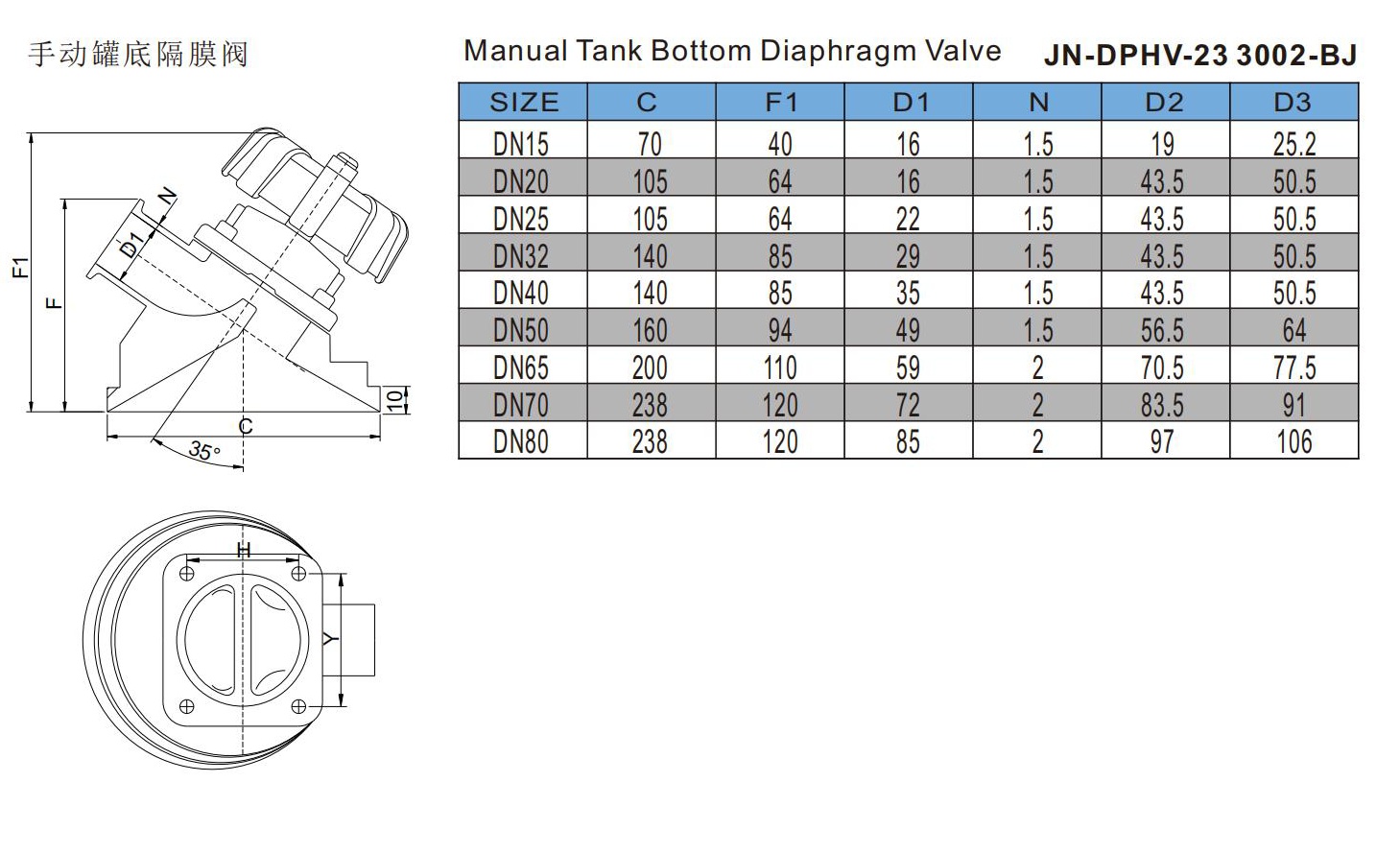

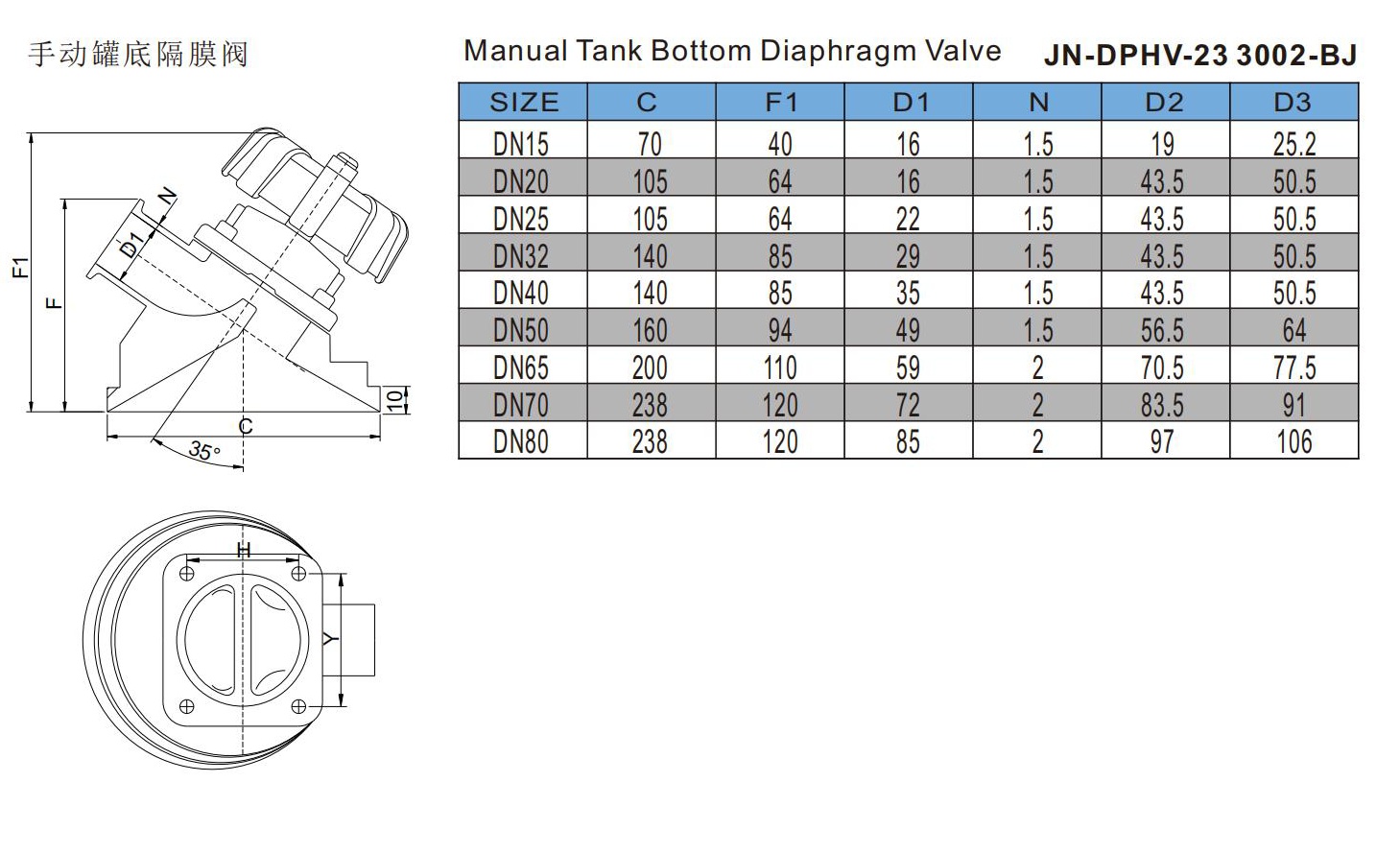

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● The stainless steel sanitary pneumatic tank bottom valve can maintain efficient and stable working performance even in a humid environment for a long time, and the pneumatic system is not easily affected by moisture.

● The sealing component design of the stainless steel sanitary pneumatic tank bottom valve has a self-cleaning function, which can reduce fouling during operation and avoid bacteria and material accumulation.

● The surface of the stainless steel sanitary pneumatic tank bottom valve body adopts an anti-static coating to reduce static electricity accumulation and prevent sparks generated by static electricity from causing pollution or safety hazards to the environment or materials.

● The stainless steel sanitary pneumatic tank bottom valve adopts a multi-layer sealing design, which can achieve higher sealing, especially suitable for the discharge of high-viscosity materials or particulate matter.

● The stainless steel sanitary pneumatic tank bottom valve seat and valve body are integrated, which reduces the connection parts, reduces the potential leakage points, and enhances the overall sealing and durability.

● The stainless steel sanitary pneumatic tank bottom valve is equipped with an impact-resistant structure, which can withstand the impact of high-pressure fluids and protect the system from pressure fluctuations.

Application

Stainless steel sanitary pneumatic tank bottom valves are used in the following industries: Food industry: ensure pollution-free discharge of fluids during food production. Pharmaceutical industry: meet the strict hygiene and emission requirements in drug production. Beverage industry: Control the efficient discharge of liquids in beverage production lines. Chemical industry: Handle the safe discharge of chemical raw materials and highly corrosive substances. Biopharmaceutical industry: Prevent fluids in biological products from being contaminated. Agricultural industry: Applied to the automatic discharge of agricultural liquid fertilizers or pesticides.

Working Principles

The working principle of the stainless steel sanitary pneumatic tank bottom valve is based on the pneumatic actuator to control the opening and closing of the valve. When the air source is input to the pneumatic actuator through the control system, the piston or diaphragm in the actuator is acted upon by air pressure, driving the sealing elements (such as the ball, valve plate or valve seat) inside the valve body to move. When the valve is open, the fluid is discharged from the bottom of the tank through the valve; when the valve is closed, the sealing element is in close contact with the valve seat to prevent fluid leakage. Using stainless steel sanitary pneumatic tank bottom valves can improve hygiene standards, automation levels and production efficiency.

The options for stainless steel sanitary pneumatic tank bottom valves include:

Valve body material: 304, 316L stainless steel.

Sealing materials: silicone, fluororubber, EPDM, etc.

Drive mode: single-acting or double-acting pneumatic actuator.

Connection mode: flange connection, threaded connection.

Control mode: manual, automatic control or remote control.

Valve types: ball, butterfly, slide valve, etc.

Specification Chart

Size | 1 ½ “to 3” |

Material | SS316L |

Seals | EPDM, PTFE |

Max. temperature | -10℃ ~ 120℃ |

Max. pressure | 0 to 10 bar |

End connections | flanged, welded, clamped |

Features

● The stainless steel sanitary pneumatic tank bottom valve can maintain efficient and stable working performance even in a humid environment for a long time, and the pneumatic system is not easily affected by moisture.

● The sealing component design of the stainless steel sanitary pneumatic tank bottom valve has a self-cleaning function, which can reduce fouling during operation and avoid bacteria and material accumulation.

● The surface of the stainless steel sanitary pneumatic tank bottom valve body adopts an anti-static coating to reduce static electricity accumulation and prevent sparks generated by static electricity from causing pollution or safety hazards to the environment or materials.

● The stainless steel sanitary pneumatic tank bottom valve adopts a multi-layer sealing design, which can achieve higher sealing, especially suitable for the discharge of high-viscosity materials or particulate matter.

● The stainless steel sanitary pneumatic tank bottom valve seat and valve body are integrated, which reduces the connection parts, reduces the potential leakage points, and enhances the overall sealing and durability.

● The stainless steel sanitary pneumatic tank bottom valve is equipped with an impact-resistant structure, which can withstand the impact of high-pressure fluids and protect the system from pressure fluctuations.

Application

Stainless steel sanitary pneumatic tank bottom valves are used in the following industries: Food industry: ensure pollution-free discharge of fluids during food production. Pharmaceutical industry: meet the strict hygiene and emission requirements in drug production. Beverage industry: Control the efficient discharge of liquids in beverage production lines. Chemical industry: Handle the safe discharge of chemical raw materials and highly corrosive substances. Biopharmaceutical industry: Prevent fluids in biological products from being contaminated. Agricultural industry: Applied to the automatic discharge of agricultural liquid fertilizers or pesticides.