| Availability: | |

|---|---|

| Quantity: | |

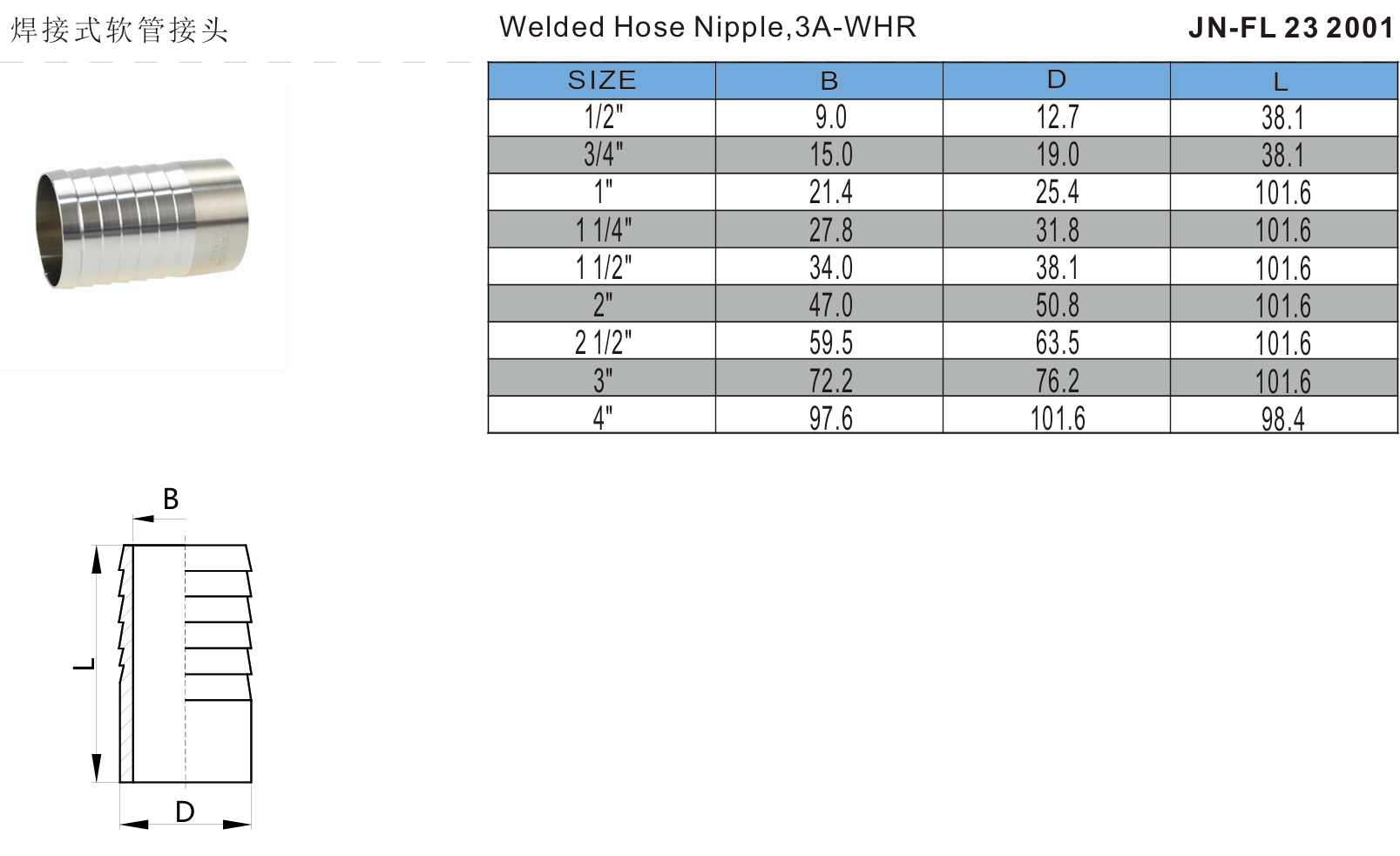

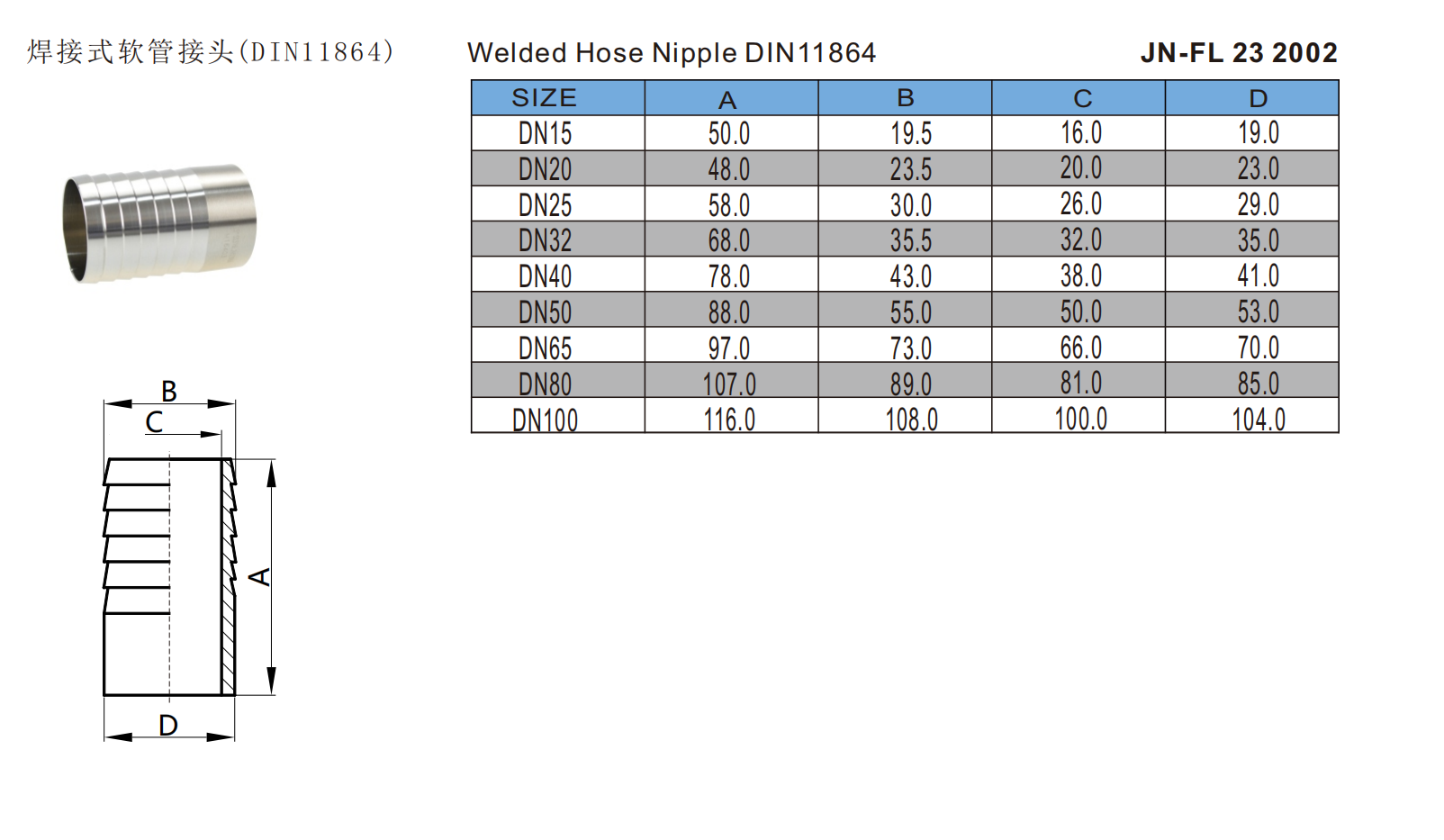

JN-FL 23 2002

JONENG

7307290000

Stainless Steel FDA Thread Electrolytic Polishing Hose Pipe Connector

The purpose of the design of stainless steel sanitary hose connectors is to provide a reliable, hygienic and efficient fluid connection method, which is particularly suitable for industries with extremely high hygiene requirements, such as food, pharmaceuticals, and chemicals. By using stainless steel and high-quality sealing materials, the stability and durability of the connectors under high pressure, high temperature and corrosive environments are ensured. Its design can avoid leakage and contamination, ensure that the fluid is not contaminated during transportation, meet hygiene standards, and facilitate cleaning and maintenance, extending the service life of the equipment.

Working Principle

The working principle of the stainless steel sanitary hose connector is to tightly connect the connector body with the hose through the precision-designed connector body, fix the hose to the connector with the clamping nut and the sealing ring, and ensure the connection is stable and leak-free through threads or clamps. The sealing ring forms a seal under pressure to prevent fluid leakage. The connector is made of stainless steel to ensure its stability and durability in high temperature, high pressure and corrosive environments, and is widely used in fluid transportation and control systems.

The options of stainless steel sanitary hose connectors include:

Drive mode: manual, quick connection, threaded connection.

Sealing material: EPDM, Viton, PTFE, etc.

Connection mode: clamp type, threaded type, flange type, welding type.

Size: Different size options are available according to pipeline specifications.

Surface treatment: polishing, sandblasting, pickling, etc.

Specification Chart

| Material | SS304, SS316L | |

| Diameter | 1 "to 24" | |

| Length | 95mm to 265mm | |

| Standard | DIN, ISO, ASTM | |

| Max pressure | up to 10 bar | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Working temperatur | -15℃ to +160℃ | |

| End connections | Flanged, Threaded | |

| Gasket or seals | Viton, PTFEE | |

Features

● The stainless steel sanitary hose connector is made of 304 and 316L stainless steel, which meets the hygiene standards of the food and pharmaceutical industries.

● The stainless steel sanitary hose connector is designed with a sealing ring (such as EPDM, Viton, etc.) to ensure sealing.

● The stainless steel sanitary hose connector adopts a quick connection design, which can be easily installed and removed without tools.

● The stainless steel sanitary hose connector is compatible with many types of hoses (such as silicone tubes, polyurethane tubes, etc.).

● The stainless steel sanitary hose connector adopts advanced processing technology, the connector surface is smooth and flawless, and the dimensional accuracy is high.

● The stainless steel sanitary hose connector has strong impact resistance and adapts to instantaneous pressure fluctuations.

Application

Stainless steel sanitary hose connectors are widely used in the following industry fields: Food and Beverage: used for liquid delivery and pipeline connection to ensure hygiene. Pharmaceutical: In drug production and fluid control, maintain the sterility of the system. Chemical: used for chemical delivery to ensure the safety and stability of the fluid. Biological products: used in the production of biological products to ensure no pollution. Dairy: In the process of dairy processing, fluid transmission and pipeline connection.

Working Principle

The working principle of the stainless steel sanitary hose connector is to tightly connect the connector body with the hose through the precision-designed connector body, fix the hose to the connector with the clamping nut and the sealing ring, and ensure the connection is stable and leak-free through threads or clamps. The sealing ring forms a seal under pressure to prevent fluid leakage. The connector is made of stainless steel to ensure its stability and durability in high temperature, high pressure and corrosive environments, and is widely used in fluid transportation and control systems.

The options of stainless steel sanitary hose connectors include:

Drive mode: manual, quick connection, threaded connection.

Sealing material: EPDM, Viton, PTFE, etc.

Connection mode: clamp type, threaded type, flange type, welding type.

Size: Different size options are available according to pipeline specifications.

Surface treatment: polishing, sandblasting, pickling, etc.

Specification Chart

| Material | SS304, SS316L | |

| Diameter | 1 "to 24" | |

| Length | 95mm to 265mm | |

| Standard | DIN, ISO, ASTM | |

| Max pressure | up to 10 bar | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Working temperatur | -15℃ to +160℃ | |

| End connections | Flanged, Threaded | |

| Gasket or seals | Viton, PTFEE | |

Features

● The stainless steel sanitary hose connector is made of 304 and 316L stainless steel, which meets the hygiene standards of the food and pharmaceutical industries.

● The stainless steel sanitary hose connector is designed with a sealing ring (such as EPDM, Viton, etc.) to ensure sealing.

● The stainless steel sanitary hose connector adopts a quick connection design, which can be easily installed and removed without tools.

● The stainless steel sanitary hose connector is compatible with many types of hoses (such as silicone tubes, polyurethane tubes, etc.).

● The stainless steel sanitary hose connector adopts advanced processing technology, the connector surface is smooth and flawless, and the dimensional accuracy is high.

● The stainless steel sanitary hose connector has strong impact resistance and adapts to instantaneous pressure fluctuations.

Application

Stainless steel sanitary hose connectors are widely used in the following industry fields: Food and Beverage: used for liquid delivery and pipeline connection to ensure hygiene. Pharmaceutical: In drug production and fluid control, maintain the sterility of the system. Chemical: used for chemical delivery to ensure the safety and stability of the fluid. Biological products: used in the production of biological products to ensure no pollution. Dairy: In the process of dairy processing, fluid transmission and pipeline connection.