| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Food Grade Quick-install Constant Back Pressure Valve

The goal of the stainless steel sanitary quick-install constant pressure valve design is to maintain a stable pressure in the pipeline system to ensure that the fluid is not affected by fluctuations during the flow process. By automatically or manually adjusting the valve, it can achieve pressure control and improve the stability, efficiency, and safety of system operation. The valve is particularly suitable for industries such as food, beverages, and pharmaceuticals, meets high hygiene requirements, avoids fluid contamination, and optimizes energy consumption and reduces the risk of equipment failure.

Working Principles

The working principle of the stainless steel sanitary quick-install constant pressure valve is to ensure that the system maintains a constant pressure by automatically adjusting the pressure in the pipeline. When the system pressure fluctuates, the pressure sensing element in the valve (such as a diaphragm or spring) will monitor these changes and adjust the valve opening according to the set pressure value. If the pressure is too high, the valve will automatically open to discharge part of the fluid; if the pressure is too low, the valve will close or reduce the opening to maintain a stable pressure to ensure the safety and stable operation of the fluid system. Using a stainless steel sanitary quick-install constant pressure valve can improve system efficiency, reduce energy consumption and maintenance costs, and extend the service life of the equipment.

The options of the stainless steel sanitary quick-install constant pressure valve include: Material: 304 stainless steel or 316L stainless steel; Adjustment method: manual adjustment or automatic adjustment; Connection method: quick-install connection; Pressure range: to adapt to different pressure requirements; Sealing materials: such as PTFE, silicone, etc.

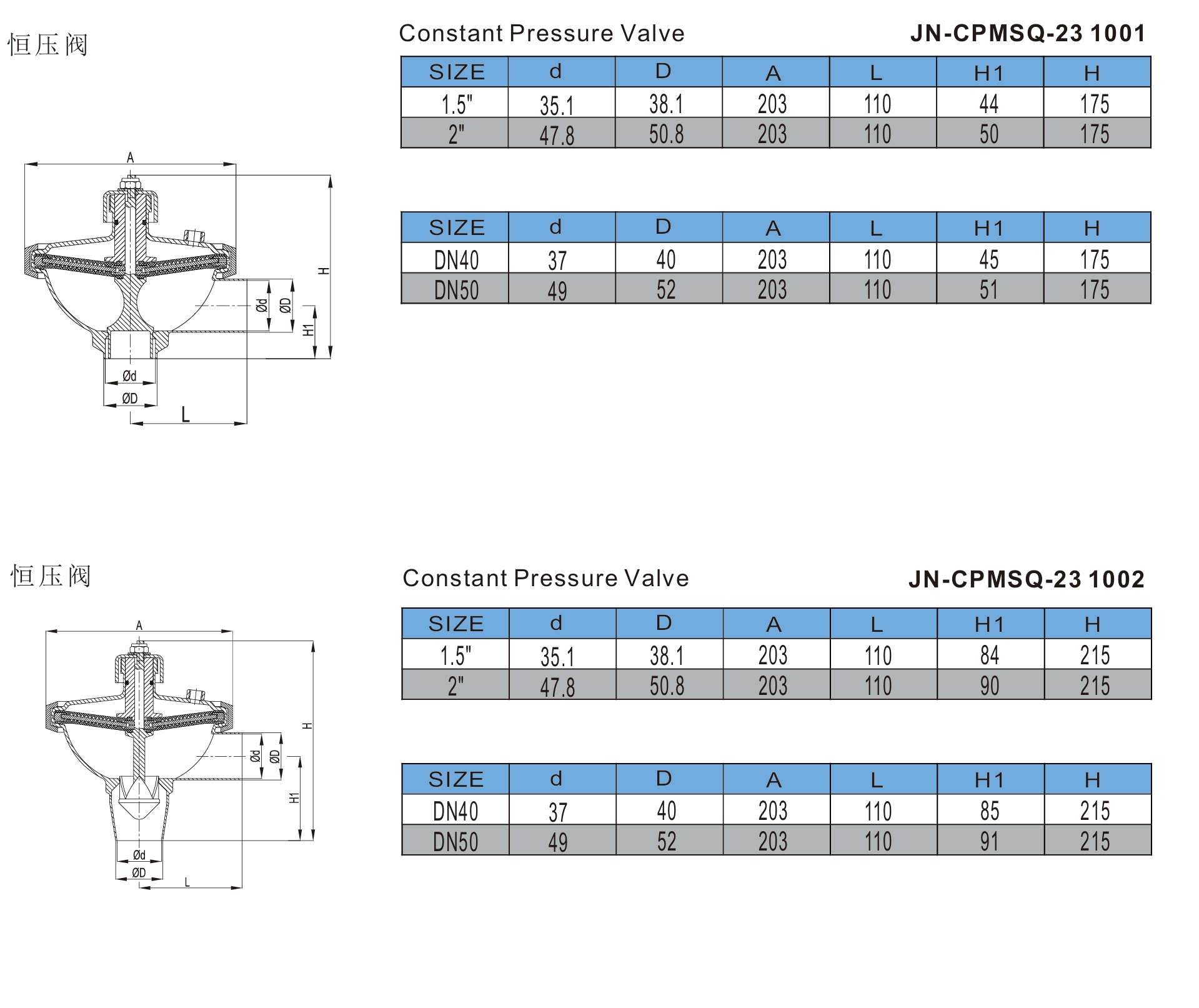

Specification Chart

Size | 1” to 2 ½ “ |

Material | SS304, SS316L |

Max. air pressure | 0 to 8 bar |

Max. product pressure | 0 to 10 bae |

Temperature | -10 °C to 140 °C |

End connections | Welded, threaded connection |

Seals and gasket | PTFE, EPDM,NBR |

Features

● The stainless steel sanitary quick-install constant pressure valve is equipped with a quick-install interface, which is easy to install and suitable for quick disassembly and cleaning.

● The stainless steel sanitary quick-install constant pressure valve has a built-in pressure regulating device to control and maintain the system pressure within the set range in real time.

● The stainless steel sanitary quick-install constant pressure valve uses high-quality sealing materials such as PTFE and silicone to ensure the sealing performance of the valve.

● The stainless steel sanitary quick-install constant pressure valve has a good impact resistance design to prevent pressure fluctuations caused by fluid impact.

● The optimized fluid channel design of the stainless steel sanitary quick-install constant pressure valve minimizes the resistance when the fluid passes through

● When the system pressure of the stainless steel sanitary quick-install constant pressure valve exceeds the set range, the valve can effectively protect the system from damage.

Application

Stainless steel sanitary quick-install constant pressure valves are mainly used in the following industry fields: Food and beverage industry: used for liquid fluid control, maintain constant pressure in the pipeline system, and ensure product quality. Pharmaceutical industry: used for liquid and gas control in pharmaceutical production, in accordance with strict hygiene requirements. Cosmetic industry: used for precise control of liquid flow and pressure in the production process of cosmetics. Chemical industry: Provide stable pressure regulation in the production process of chemicals. Dairy processing: used for the production and fluid control of milk and other dairy products. Water treatment industry: Regulate pressure in water treatment systems to ensure the normal operation of the system.

Working Principles

The working principle of the stainless steel sanitary quick-install constant pressure valve is to ensure that the system maintains a constant pressure by automatically adjusting the pressure in the pipeline. When the system pressure fluctuates, the pressure sensing element in the valve (such as a diaphragm or spring) will monitor these changes and adjust the valve opening according to the set pressure value. If the pressure is too high, the valve will automatically open to discharge part of the fluid; if the pressure is too low, the valve will close or reduce the opening to maintain a stable pressure to ensure the safety and stable operation of the fluid system. Using a stainless steel sanitary quick-install constant pressure valve can improve system efficiency, reduce energy consumption and maintenance costs, and extend the service life of the equipment.

The options of the stainless steel sanitary quick-install constant pressure valve include: Material: 304 stainless steel or 316L stainless steel; Adjustment method: manual adjustment or automatic adjustment; Connection method: quick-install connection; Pressure range: to adapt to different pressure requirements; Sealing materials: such as PTFE, silicone, etc.

Specification Chart

Size | 1” to 2 ½ “ |

Material | SS304, SS316L |

Max. air pressure | 0 to 8 bar |

Max. product pressure | 0 to 10 bae |

Temperature | -10 °C to 140 °C |

End connections | Welded, threaded connection |

Seals and gasket | PTFE, EPDM,NBR |

Features

● The stainless steel sanitary quick-install constant pressure valve is equipped with a quick-install interface, which is easy to install and suitable for quick disassembly and cleaning.

● The stainless steel sanitary quick-install constant pressure valve has a built-in pressure regulating device to control and maintain the system pressure within the set range in real time.

● The stainless steel sanitary quick-install constant pressure valve uses high-quality sealing materials such as PTFE and silicone to ensure the sealing performance of the valve.

● The stainless steel sanitary quick-install constant pressure valve has a good impact resistance design to prevent pressure fluctuations caused by fluid impact.

● The optimized fluid channel design of the stainless steel sanitary quick-install constant pressure valve minimizes the resistance when the fluid passes through

● When the system pressure of the stainless steel sanitary quick-install constant pressure valve exceeds the set range, the valve can effectively protect the system from damage.

Application

Stainless steel sanitary quick-install constant pressure valves are mainly used in the following industry fields: Food and beverage industry: used for liquid fluid control, maintain constant pressure in the pipeline system, and ensure product quality. Pharmaceutical industry: used for liquid and gas control in pharmaceutical production, in accordance with strict hygiene requirements. Cosmetic industry: used for precise control of liquid flow and pressure in the production process of cosmetics. Chemical industry: Provide stable pressure regulation in the production process of chemicals. Dairy processing: used for the production and fluid control of milk and other dairy products. Water treatment industry: Regulate pressure in water treatment systems to ensure the normal operation of the system.