| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary self-priming single-stage centrifugal pump is a device designed for fluid transportation. It is made of stainless steel to ensure that it is used in an environment with high sanitation requirements. The stainless steel sanitary self-priming single-stage centrifugal pump is mainly used in pipelines in the food, beverage, pharmaceutical and other industries. It is usually installed at the inlet and outlet of the fluid and is particularly suitable for starting without water filling. According to different needs and application environments, the stainless steel sanitary self-priming single-stage centrifugal pump mainly has the following types: standard self-priming centrifugal pump, high-temperature self-priming centrifugal pump, corrosion-resistant self-priming centrifugal pump, food-grade self-priming centrifugal pump, chemical self-priming centrifugal pump.

JONENG

8481804090

Stainless Steel Food Grade Self Priming Single Stage Centrifugal Pump

The stainless steel sanitary self-priming single-stage centrifugal pump is designed to ensure efficient fluid transportation in a sterile and pollution-free environment. It is particularly suitable for occasions that require self-priming function and can start quickly and run stably without external water filling. Through precise structural design, it not only reduces energy consumption, but also improves the reliability of the system. The pump body is made of sanitary stainless steel, which meets the sanitation requirements of the food, pharmaceutical and other industries. At the same time, it has the advantages of corrosion resistance and easy cleaning, ensuring the purity and safety of the fluid.

Working Principles

The working principle of the stainless steel sanitary self-priming single-stage centrifugal pump combines self-priming technology and centrifugal force. When the pump is started, the centrifugal force generated by the rotation of the impeller quickly forms a negative pressure in the pump chamber through the air or liquid in the suction pipe, and pushes the gas and liquid mixture to the impeller. Through centrifugal action, the mixture is accelerated to flow, the gas is gradually discharged, and the liquid is pressed to the outlet.

The options of the stainless steel sanitary self-priming single-stage centrifugal pump include:

Flow and head: different flow and head can be selected according to needs.

Seal type: single-end or double-end mechanical seal.

Material: 304 or 316L stainless steel.

Connection method: flange connection, threaded connection, quick connection.

Motor type: standard motor or explosion-proof motor.

Temperature range: design to adapt to different temperature requirements.

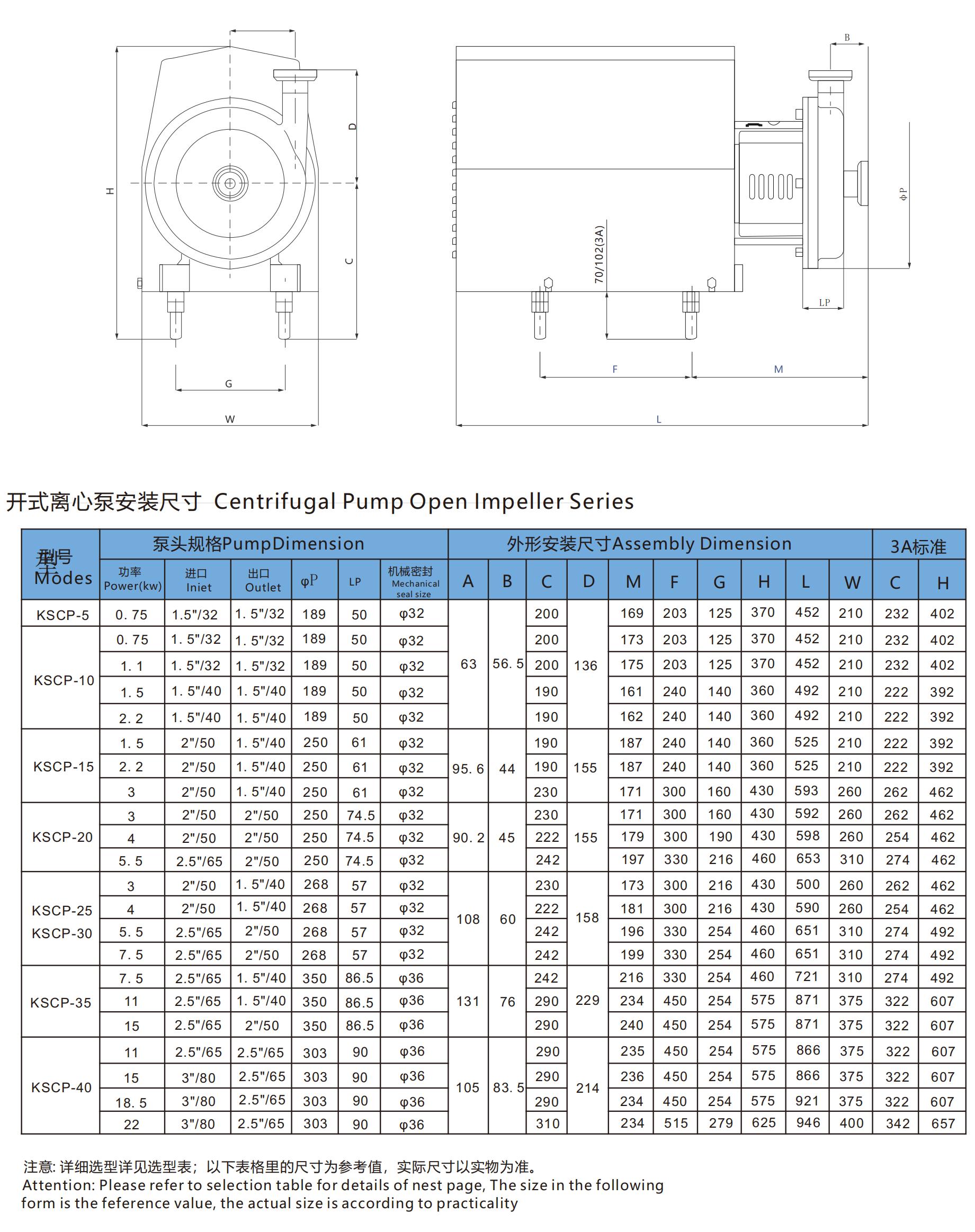

Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Max pressur | 7bar |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

Frequency | 50HZ/60HZ |

Features

● The stainless steel sanitary self-priming single-stage centrifugal pump has the function of quickly sucking gas. It does not require external water filling when starting, and can automatically remove air or bubbles in the pipeline.

● The stainless steel sanitary self-priming single-stage centrifugal pump adopts a dead angle design inside the pump body to avoid liquid retention, meet strict hygiene standards, and ensure no pollution.

● The stainless steel sanitary self-priming single-stage centrifugal pump adopts a precision impeller design, which can effectively reduce energy loss and ensure the stability and efficiency of the pump during operation.

● The pump body and pump cover of the stainless steel sanitary self-priming single-stage centrifugal pump use highly corrosion-resistant materials such as 316L stainless steel, which are suitable for the transportation of various corrosive fluids such as acids, alkalis, and salt solutions.

● The stainless steel sanitary self-priming single-stage centrifugal pump has a compact design and a small footprint, which is suitable for places with limited space.

● The stainless steel sanitary self-priming single-stage centrifugal pump adopts a silent impeller and an optimized pump body structure to reduce the noise when the pump is running.

Application

Stainless steel sanitary self-priming single-stage centrifugal pumps are widely used in the following industries: Food and Beverage: used for the transportation of liquids such as juice, milk, and beer. Pharmaceuticals: transport drugs and biological products to ensure hygiene and pollution-free. Cosmetics: transmission of liquid raw materials, such as flavors, emulsions, etc. Chemicals: used for the transportation of corrosive fluids. Water treatment: used for liquid transportation in water purification and wastewater treatment.

Working Principles

The working principle of the stainless steel sanitary self-priming single-stage centrifugal pump combines self-priming technology and centrifugal force. When the pump is started, the centrifugal force generated by the rotation of the impeller quickly forms a negative pressure in the pump chamber through the air or liquid in the suction pipe, and pushes the gas and liquid mixture to the impeller. Through centrifugal action, the mixture is accelerated to flow, the gas is gradually discharged, and the liquid is pressed to the outlet.

The options of the stainless steel sanitary self-priming single-stage centrifugal pump include:

Flow and head: different flow and head can be selected according to needs.

Seal type: single-end or double-end mechanical seal.

Material: 304 or 316L stainless steel.

Connection method: flange connection, threaded connection, quick connection.

Motor type: standard motor or explosion-proof motor.

Temperature range: design to adapt to different temperature requirements.

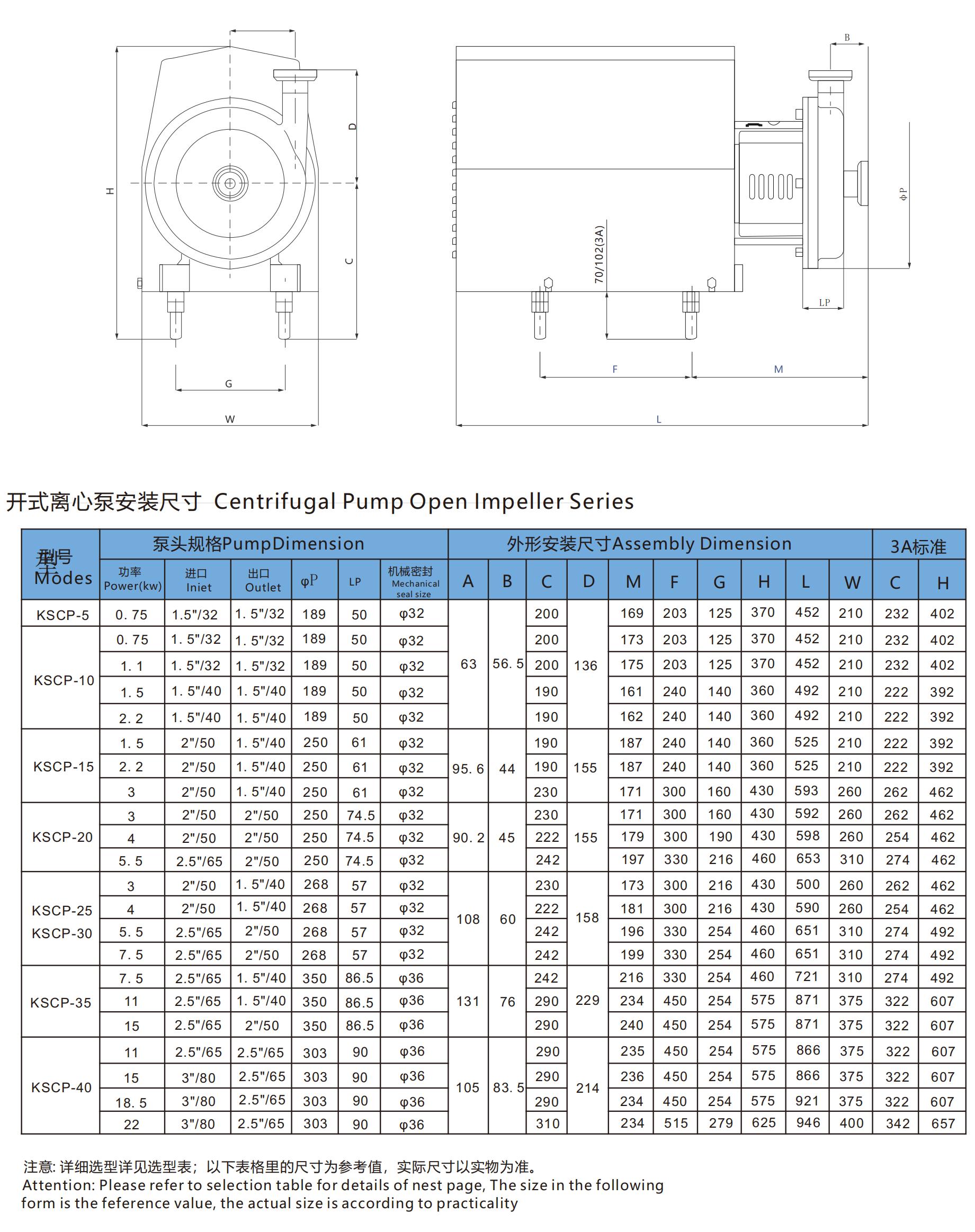

Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

| Motor type | variable frequency motor, fixed speed motor |

Frequency | 50HZ/60HZ |

Max. pressure | 7 bar |

Max. temperature | 120°C |

Material | SS304/SS316L |

| Inlet/outlet connection | Clamp, Weld, Flange |

| Inlet/outlet size | 1”-3” |

| Diaphragm | PTFE, PTFE with white back, EPDM, white EPDM, white NBR |

| Driving way | Air or Motor |

Features

● The stainless steel sanitary self-priming single-stage centrifugal pump has the function of quickly sucking gas. It does not require external water filling when starting, and can automatically remove air or bubbles in the pipeline.

● The stainless steel sanitary self-priming single-stage centrifugal pump adopts a dead angle design inside the pump body to avoid liquid retention, meet strict hygiene standards, and ensure no pollution.

● The stainless steel sanitary self-priming single-stage centrifugal pump adopts a precision impeller design, which can effectively reduce energy loss and ensure the stability and efficiency of the pump during operation.

● The pump body and pump cover of the stainless steel sanitary self-priming single-stage centrifugal pump use highly corrosion-resistant materials such as 316L stainless steel, which are suitable for the transportation of various corrosive fluids such as acids, alkalis, and salt solutions.

● The stainless steel sanitary self-priming single-stage centrifugal pump has a compact design and a small footprint, which is suitable for places with limited space.

● The stainless steel sanitary self-priming single-stage centrifugal pump adopts a silent impeller and an optimized pump body structure to reduce the noise when the pump is running.

Application

Stainless steel sanitary self-priming single-stage centrifugal pumps are widely used in the following industries: Food and Beverage: used for the transportation of liquids such as juice, milk, and beer. Pharmaceuticals: transport drugs and biological products to ensure hygiene and pollution-free. Cosmetics: transmission of liquid raw materials, such as flavors, emulsions, etc. Chemicals: used for the transportation of corrosive fluids. Water treatment: used for liquid transportation in water purification and wastewater treatment.