| Availability: | |

|---|---|

| Quantity: | |

Stainless steel sanitary centrifugal pump is a fluid conveying equipment designed for industries with high sanitation requirements. It is mainly used for fluid conveying, especially for places with high sanitation requirements, to ensure that the liquid is not contaminated during the conveying process and can work efficiently and stably.

Stainless steel sanitary centrifugal pumps are usually used in liquid conveying pipelines in industries such as food, pharmaceuticals, and cosmetics. They are installed in liquid storage, processing, and packaging to ensure the sanitation and safe transmission of fluids. The main types of stainless steel sanitary centrifugal pumps include: single-stage centrifugal pumps, multi-stage centrifugal pumps, self-priming centrifugal pumps, magnetic drive centrifugal pumps, and sanitary rotor pumps.

JONENG

8481804090

The design goal of stainless steel sanitary centrifugal pumps is to provide efficient, reliable and hygienic fluid conveying solutions. It is designed for the delivery of liquids or slurries in industries such as food, beverages, and pharmaceuticals, and has excellent corrosion resistance, anti-pollution and efficient pumping performance. Its main goal is to improve production efficiency, ensure fluid quality, and meet high standards of sanitation requirements.

Working Principles

The stainless steel sanitary centrifugal pump drives the impeller to rotate through an electric motor, generating centrifugal force to push the liquid from the center of the impeller to the outer edge, forming a high-pressure fluid and delivering it through the pump outlet. This principle enables centrifugal pumps to deliver liquids continuously and stably, and are widely used in situations where liquid hygiene and safety need to be maintained.

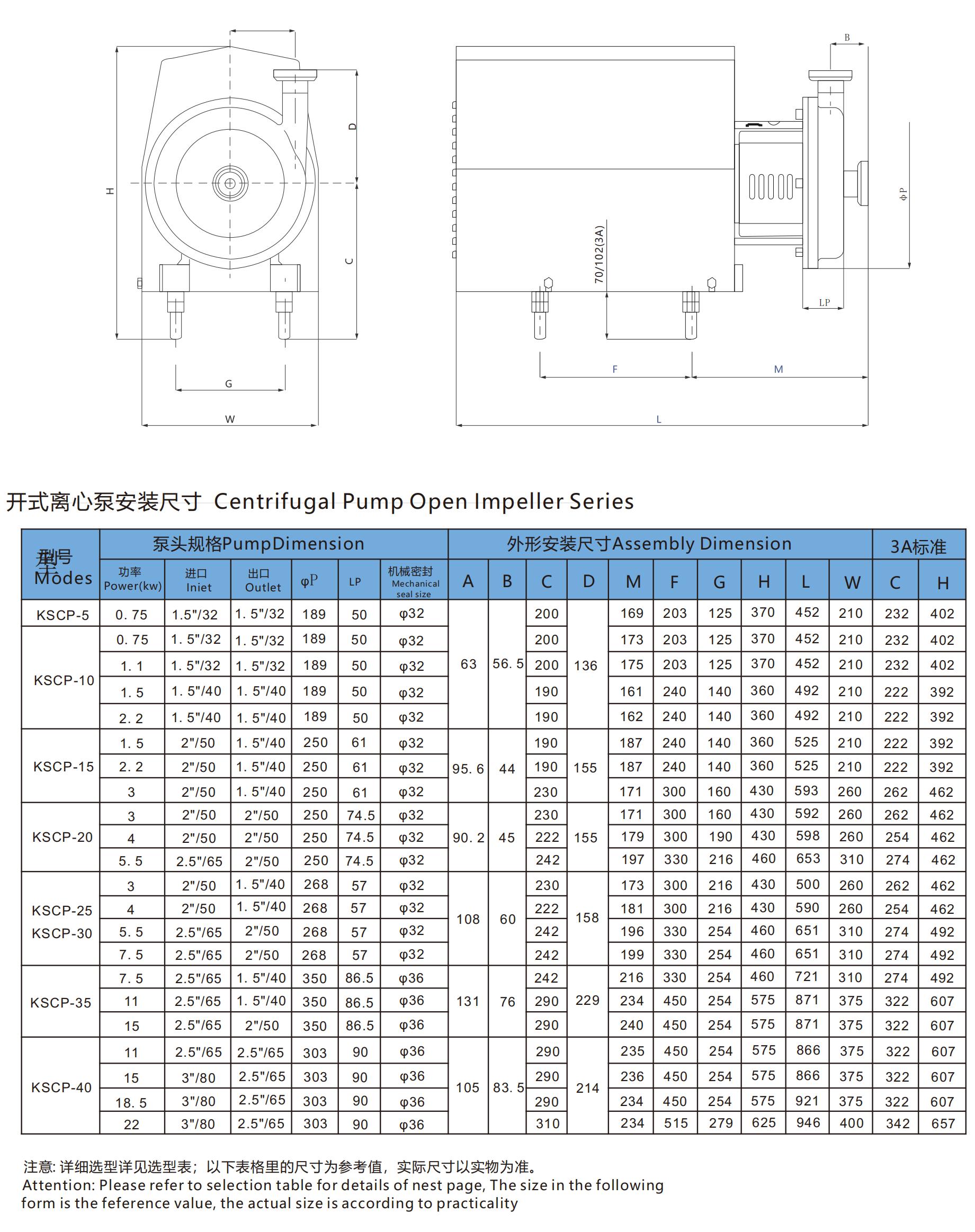

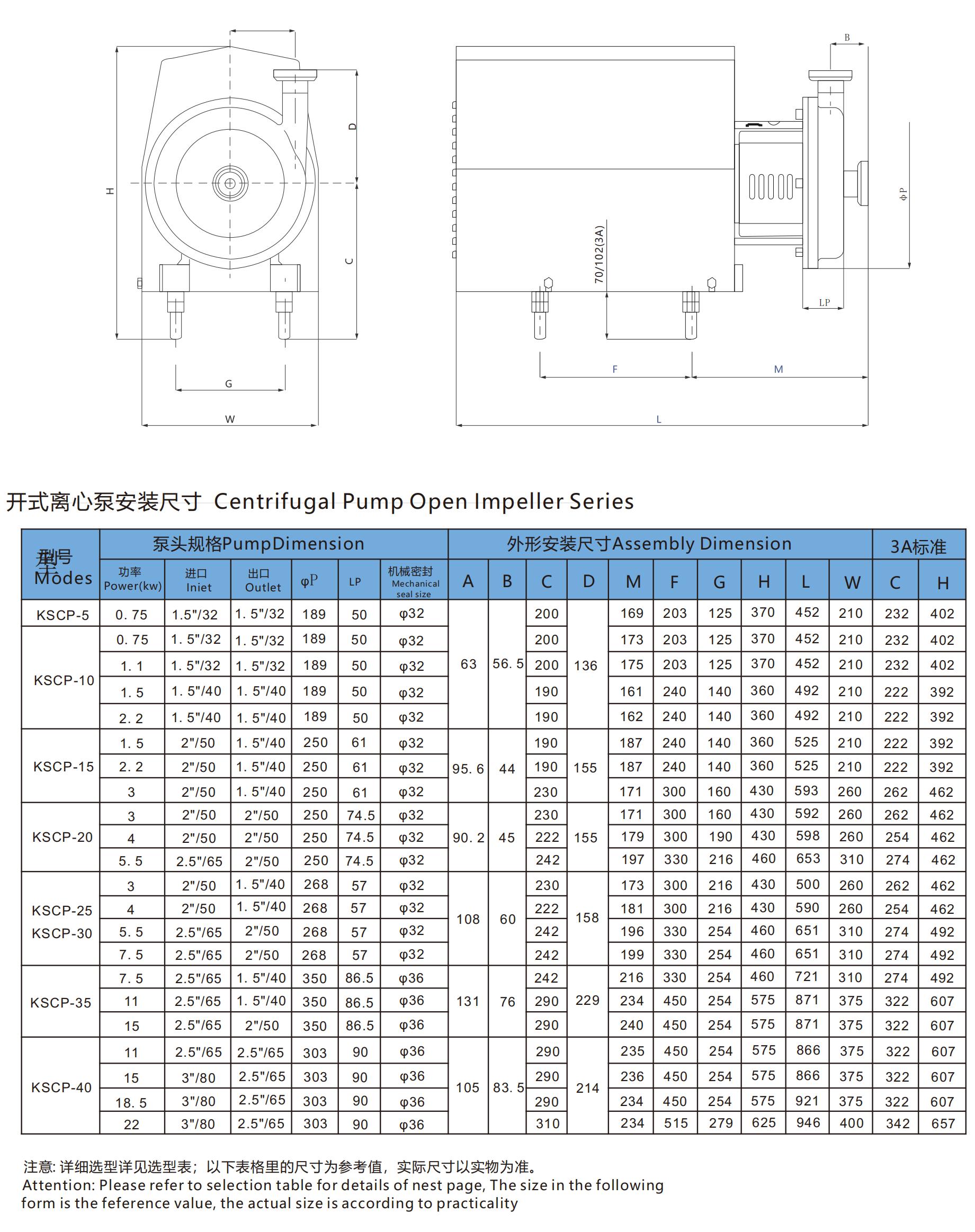

Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Max pressur | 7bar |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

Frequency | 50HZ/60HZ |

Features

● The pump body and pump cover are usually designed with no dead angle and smooth surface to avoid liquid accumulation in the pump body or bacteria breeding places.

● The pump body and key components are made of 304 or 316L stainless steel materials, which have excellent corrosion resistance and high temperature resistance, and are suitable for harsh environments.

● The design focuses on the fluid dynamics optimization of the impeller, reduces fluid resistance, and increases the flow and head of the pump.

● Adopt efficient mechanical sealing technology to ensure the sealing between the pump shaft and the pump body to prevent liquid leakage.

● Usually adopt a detachable structural design for easy maintenance, cleaning and inspection.

● The precise impeller and pump body design reduces the resistance of the fluid channel, and the pump runs more smoothly and with lower noise.

Application

Stainless steel sanitary centrifugal pumps are widely used in the following fields: Food and beverage industry: conveying liquids, juices, dairy products, etc. to ensure hygiene and safety. Pharmaceutical industry: conveying liquid medicines and biological products to avoid contamination. Cosmetic industry: used for conveying emulsions and pastes. Chemical industry: used for the transmission of chemical liquids to ensure no pollution. Water treatment industry: used for liquid conveying in water treatment systems.

Working Principles

The stainless steel sanitary centrifugal pump drives the impeller to rotate through an electric motor, generating centrifugal force to push the liquid from the center of the impeller to the outer edge, forming a high-pressure fluid and delivering it through the pump outlet. This principle enables centrifugal pumps to deliver liquids continuously and stably, and are widely used in situations where liquid hygiene and safety need to be maintained.

Feature and Specification

Stainless Steel Centrifugal Pump Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

| Motor type | variable frequency motor, fixed speed motor |

Frequency | 50HZ/60HZ |

Max. pressure | 7 bar |

Max. temperature | 120°C |

Material | SS304/SS316L |

| Inlet/outlet connection | Clamp, Weld, Flange |

| Inlet/outlet size | 1”-3” |

| Diaphragm | PTFE, PTFE with white back, EPDM, white EPDM, white NBR |

| Driving way | Air or Motor |

Features

● The pump body and pump cover are usually designed with no dead angle and smooth surface to avoid liquid accumulation in the pump body or bacteria breeding places.

● The pump body and key components are made of 304 or 316L stainless steel materials, which have excellent corrosion resistance and high temperature resistance, and are suitable for harsh environments.

● The design focuses on the fluid dynamics optimization of the impeller, reduces fluid resistance, and increases the flow and head of the pump.

● Adopt efficient mechanical sealing technology to ensure the sealing between the pump shaft and the pump body to prevent liquid leakage.

● Usually adopt a detachable structural design for easy maintenance, cleaning and inspection.

● The precise impeller and pump body design reduces the resistance of the fluid channel, and the pump runs more smoothly and with lower noise.

Application

Stainless steel sanitary centrifugal pumps are widely used in the following fields: Food and beverage industry: conveying liquids, juices, dairy products, etc. to ensure hygiene and safety. Pharmaceutical industry: conveying liquid medicines and biological products to avoid contamination. Cosmetic industry: used for conveying emulsions and pastes. Chemical industry: used for the transmission of chemical liquids to ensure no pollution. Water treatment industry: used for liquid conveying in water treatment systems.