| Availability: | |

|---|---|

| Quantity: | |

Stainless Steel High Performance Straight Three-way Ball Valve BV

Stainless steel sanitary straight-through ball valves are designed to ensure the sanitation and safety of fluid transmission. By accurately controlling the flow and direction, providing reliable sealing and preventing leakage, it meets the high hygiene requirements of food, pharmaceutical and other industries and ensures efficient and safe production processes.

Working principle

The working principle of stainless steel sanitary straight-through ball valves is to control the flow of fluid by rotating the ball. There is a ball with a hole inside the ball valve. When the hole of the ball is connected to the pipeline flow channel, the fluid can pass through; when the ball rotates 90°, the hole and the flow channel are offset, the fluid is cut off, and the purpose of closing the pipeline is achieved.

Using a stainless steel sanitary straight-through ball valve can achieve precise flow and flow direction control, ensure the safe transmission of fluid in the pipeline, and prevent leakage.

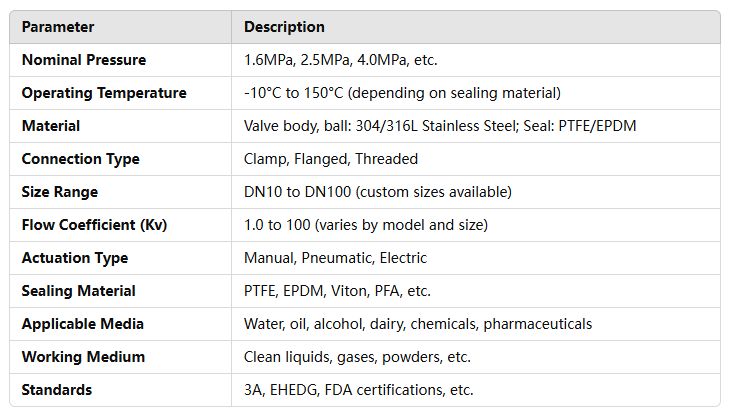

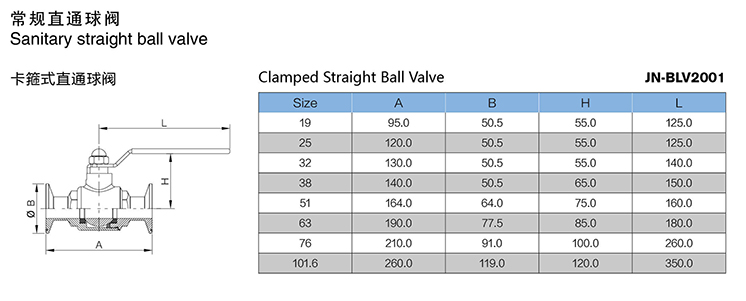

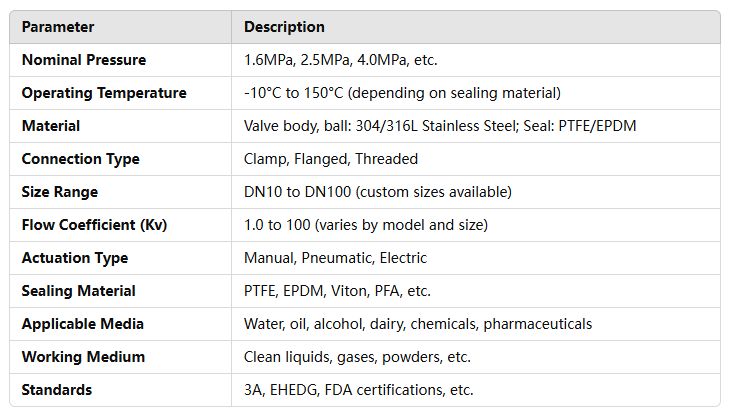

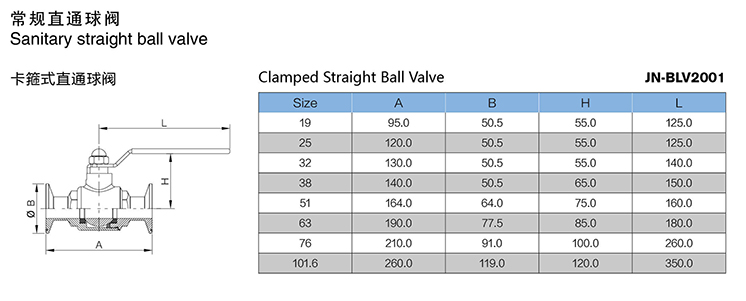

Specification Chart

Features

● There are no dead corners or narrow parts inside the ball valve, and the fluid will not be retained or accumulated during the passage process, ensuring the hygiene of the liquid.

● Made of 304 or 316L stainless steel, it is corrosion-resistant, high-temperature-resistant and wear-resistant.

● High-quality sealing materials (such as PTFE, EPDM, Viton, etc.) and precision-machined balls and valve seats are used to ensure complete sealing.

● The ball valve has a simple structure and is designed to be easy to disassemble and clean, meeting the strict hygiene requirements of the food and pharmaceutical industries.

● The flow rate is adjusted by partially rotating the ball to provide precise flow control.

● A variety of drive modes such as manual, pneumatic, and electric are provided to meet the needs of different production environments.

Application

Stainless steel sanitary straight-through ball valves are widely used in the following industries: Food and beverage: transportation and control of liquids, juices, and dairy products. Pharmaceutical industry: flow control of liquid medicines and raw materials. Cosmetics industry: precision liquid flow control. Chemical industry: control of highly corrosive liquids and gases. Water treatment industry: flow regulation of water, wastewater and other liquids.

Working principle

The working principle of stainless steel sanitary straight-through ball valves is to control the flow of fluid by rotating the ball. There is a ball with a hole inside the ball valve. When the hole of the ball is connected to the pipeline flow channel, the fluid can pass through; when the ball rotates 90°, the hole and the flow channel are offset, the fluid is cut off, and the purpose of closing the pipeline is achieved.

Using a stainless steel sanitary straight-through ball valve can achieve precise flow and flow direction control, ensure the safe transmission of fluid in the pipeline, and prevent leakage.

Specification Chart

Features

● There are no dead corners or narrow parts inside the ball valve, and the fluid will not be retained or accumulated during the passage process, ensuring the hygiene of the liquid.

● Made of 304 or 316L stainless steel, it is corrosion-resistant, high-temperature-resistant and wear-resistant.

● High-quality sealing materials (such as PTFE, EPDM, Viton, etc.) and precision-machined balls and valve seats are used to ensure complete sealing.

● The ball valve has a simple structure and is designed to be easy to disassemble and clean, meeting the strict hygiene requirements of the food and pharmaceutical industries.

● The flow rate is adjusted by partially rotating the ball to provide precise flow control.

● A variety of drive modes such as manual, pneumatic, and electric are provided to meet the needs of different production environments.

Application

Stainless steel sanitary straight-through ball valves are widely used in the following industries: Food and beverage: transportation and control of liquids, juices, and dairy products. Pharmaceutical industry: flow control of liquid medicines and raw materials. Cosmetics industry: precision liquid flow control. Chemical industry: control of highly corrosive liquids and gases. Water treatment industry: flow regulation of water, wastewater and other liquids.