| Availability: | |

|---|---|

| Quantity: | |

The centrifugal pump is ideal for pumping low or medium viscosity hygienic liquids and slurries, such as milk,juice by converting energy into velocity or kinetic energy and pressure. The open impeller design removes the dead angle which is easier to clean and keep hygienic. The centrifugal pump has the advantage of low cost and high flow so it is the most wide-use pump in the industry.

JONENG

8481804090

The centrifugal pump is ideal for pumping low or medium viscosity hygienic liquids and slurries, such as milk,juice by converting energy into velocity or kinetic energy and pressure. The open impeller design removes the dead angle which is easier to clean and keep hygienic. The centrifugal pump has the advantage of low cost and high flow so it is the most wide-use pump in the industry.

Working Principles

The pump is consist of casing, impeller, mechanical seal, shaft and motor. The impeller houses in the casing and rotates in conjunction with pump shaft. When the low or medium fluid enters the inlet, the pump will transfer the centrifugal force to generate speed which makes the impeller revolves fast. In this way, the fluid will be pushed through the outlet.

Stainless Steel Lobe Pump Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Max pressur | 7bar |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

Frequency | 50HZ/60HZ |

Features

● It is designed to be clean-in-place(CIP)

● It is easy to clean, operate and assemble

● Food grade stainless steel design meets the 3A standard

● Adjustable leg meets different requirement in application

● It is low noise but high efficiency

● Heat jacket can be as an optional choice if needed

Application

The centrifugal pump is widely used to transfer various liquids in different field, such dairy, beer, beverage, cosmetics,pharmaceuticals,chemical industry and others.

Working Principles

The pump is consist of casing, impeller, mechanical seal, shaft and motor. The impeller houses in the casing and rotates in conjunction with pump shaft. When the low or medium fluid enters the inlet, the pump will transfer the centrifugal force to generate speed which makes the impeller revolves fast. In this way, the fluid will be pushed through the outlet.

Feature and Specification

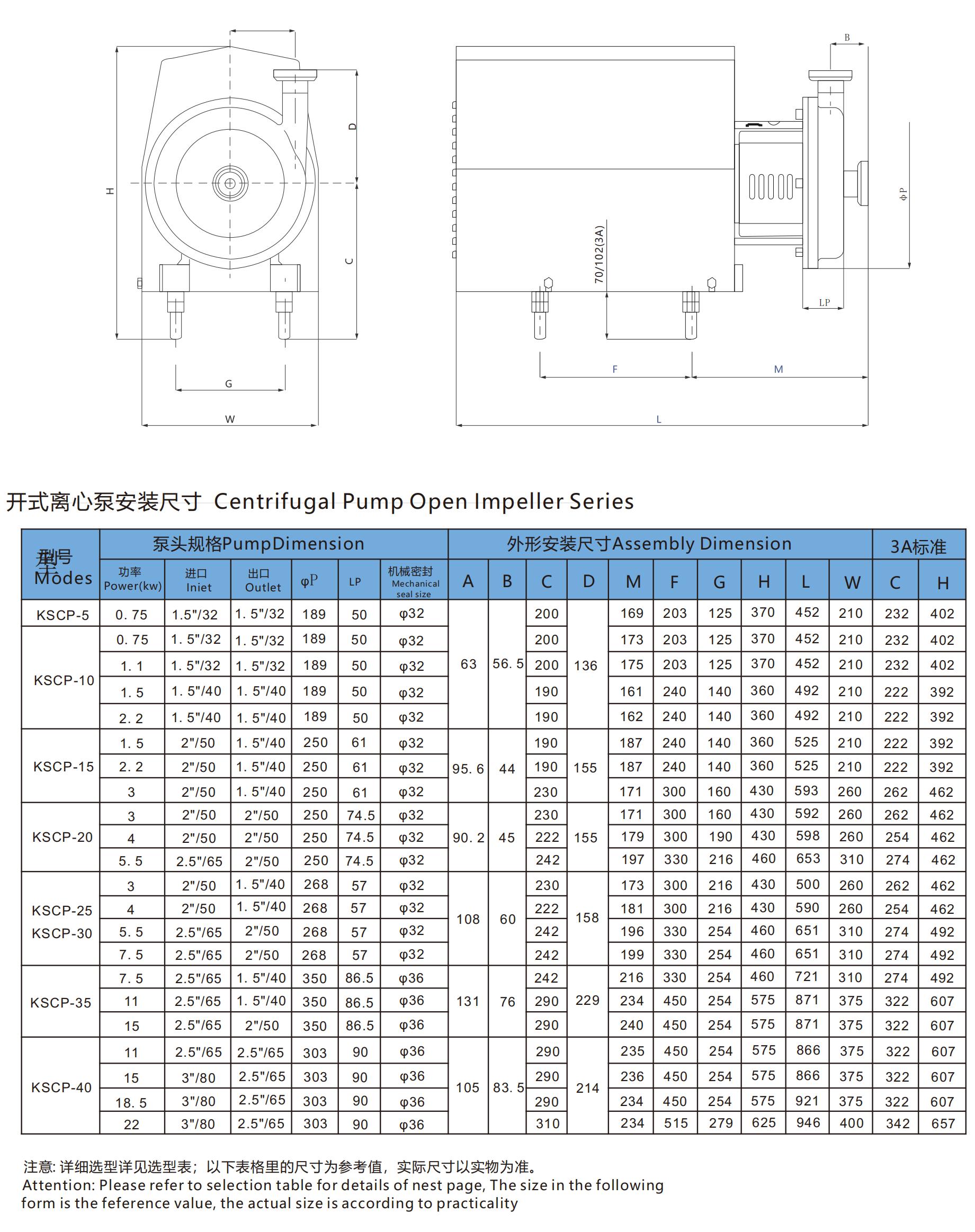

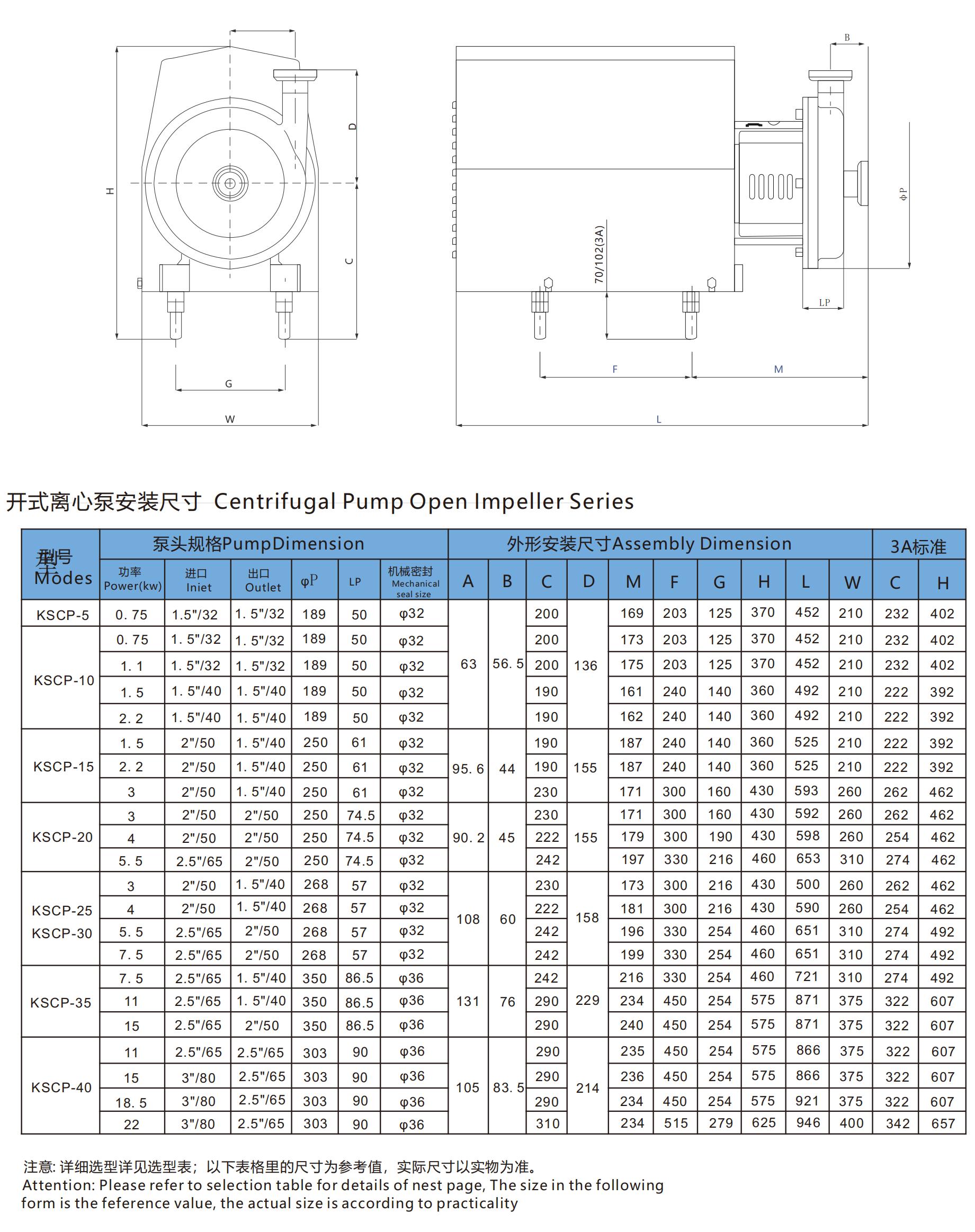

Stainless Steel Centrifugal Pump Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

| Motor type | variable frequency motor, fixed speed motor |

Frequency | 50HZ/60HZ |

Max. pressure | 7 bar |

Max. temperature | 120°C |

Material | SS304/SS316L |

| Inlet/outlet connection | Clamp, Weld, Flange |

| Inlet/outlet size | 1”-3” |

| Diaphragm | PTFE, PTFE with white back, EPDM, white EPDM, white NBR |

| Driving way | Air or Motor |

Features

● It is designed to be clean-in-place(CIP)

● It is easy to clean, operate and assemble

● Food grade stainless steel design meets the 3A standard

● Adjustable leg meets different requirement in application

● It is low noise but high efficiency

● Heat jacket can be as an optional choice if needed

Application

The centrifugal pump is widely used to transfer various liquids in different field, such dairy, beer, beverage, cosmetics,pharmaceuticals,chemical industry and others.