| Availability: | |

|---|---|

| Quantity: | |

The Stainless Steel High Suction Head Clamps Horizontal Cryogenic Centrifugal Pump is a robust pump designed for transferring low-temperature fluids. Its horizontal structure, high suction capability, and clamp connections ensure stable flow, leak-free performance, and safe operation in cryogenic processing systems.

JONENG

8481804090

The Stainless Steel High Suction Head Clamps Horizontal Cryogenic Centrifugal Pump is a robust pump designed for transferring low-temperature fluids. Its horizontal structure, high suction capability, and clamp connections ensure stable flow, leak-free performance, and safe operation in cryogenic processing systems.

Working Principles

The Stainless Steel High Suction Head Clamps Horizontal Cryogenic Centrifugal Pump works by using a high-speed rotating impeller to generate centrifugal force for moving cryogenic fluids. When the pump starts, the impeller draws low-temperature liquid into the pump inlet, even under high suction head conditions. The liquid is accelerated radially outward and guided through the volute casing, where velocity energy is converted into pressure. This design ensures stable flow while preventing cavitation in cryogenic environments. The horizontal layout improves mechanical balance and heat dissipation, while stainless steel construction and clamp connections maintain tight sealing, safety, and cleanliness during cryogenic fluid transfer

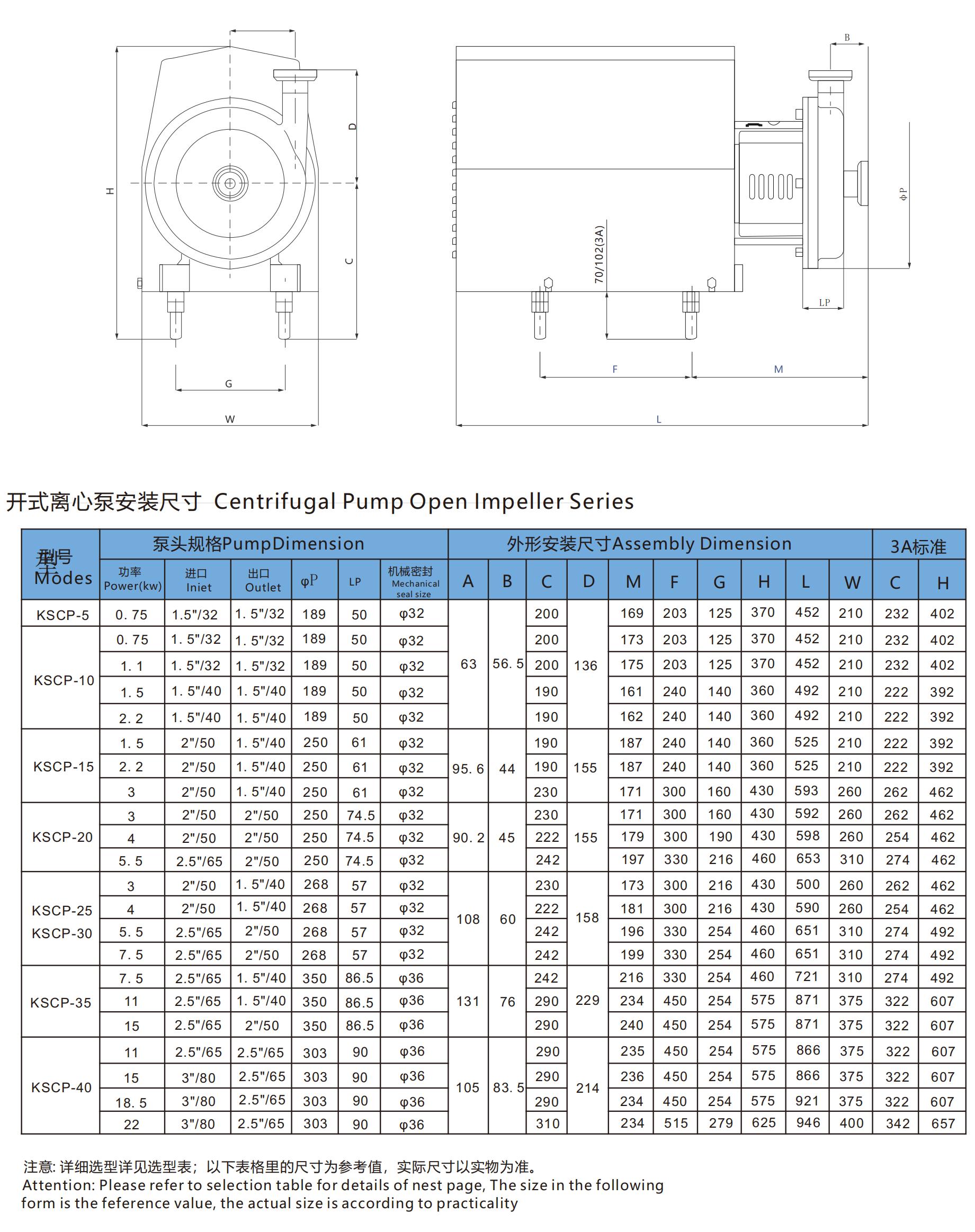

Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Max pressur | 7bar |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

Frequency | 50HZ/60HZ |

Features

The sanitary stainless steel structure provides excellent corrosion resistance and smooth internal surfaces, ensuring hygienic operation and easy cleaning in food, beverage, and pharmaceutical processing environments.

The vertical motor design saves installation space while maintaining stable alignment, reducing vibration and ensuring consistent performance during continuous liquid transfer operations.

The self-priming impeller design effectively removes air from the suction line, enabling quick startup and reliable pumping without the need for manual priming procedures.

Precision-engineered impeller and casing deliver smooth, low-pulsation flow, minimizing shear force and protecting sensitive liquids from foaming or product degradation

Application

The Stainless Steel Sanitary Motor Vertical Self Impeller Priming Centrifugal Pump is widely used in food and beverage production for transferring milk, juice, syrups, and liquid additives under hygienic conditions. It is also applied in pharmaceutical and biotechnology industries for moving purified water, solutions, and intermediates where cleanliness and reliability are essential. Additionally, it supports cosmetic and chemical processing lines requiring corrosion resistance and stable, contamination-free liquid handling.

Working Principles

The Stainless Steel High Suction Head Clamps Horizontal Cryogenic Centrifugal Pump works by using a high-speed rotating impeller to generate centrifugal force for moving cryogenic fluids. When the pump starts, the impeller draws low-temperature liquid into the pump inlet, even under high suction head conditions. The liquid is accelerated radially outward and guided through the volute casing, where velocity energy is converted into pressure. This design ensures stable flow while preventing cavitation in cryogenic environments. The horizontal layout improves mechanical balance and heat dissipation, while stainless steel construction and clamp connections maintain tight sealing, safety, and cleanliness during cryogenic fluid transfer

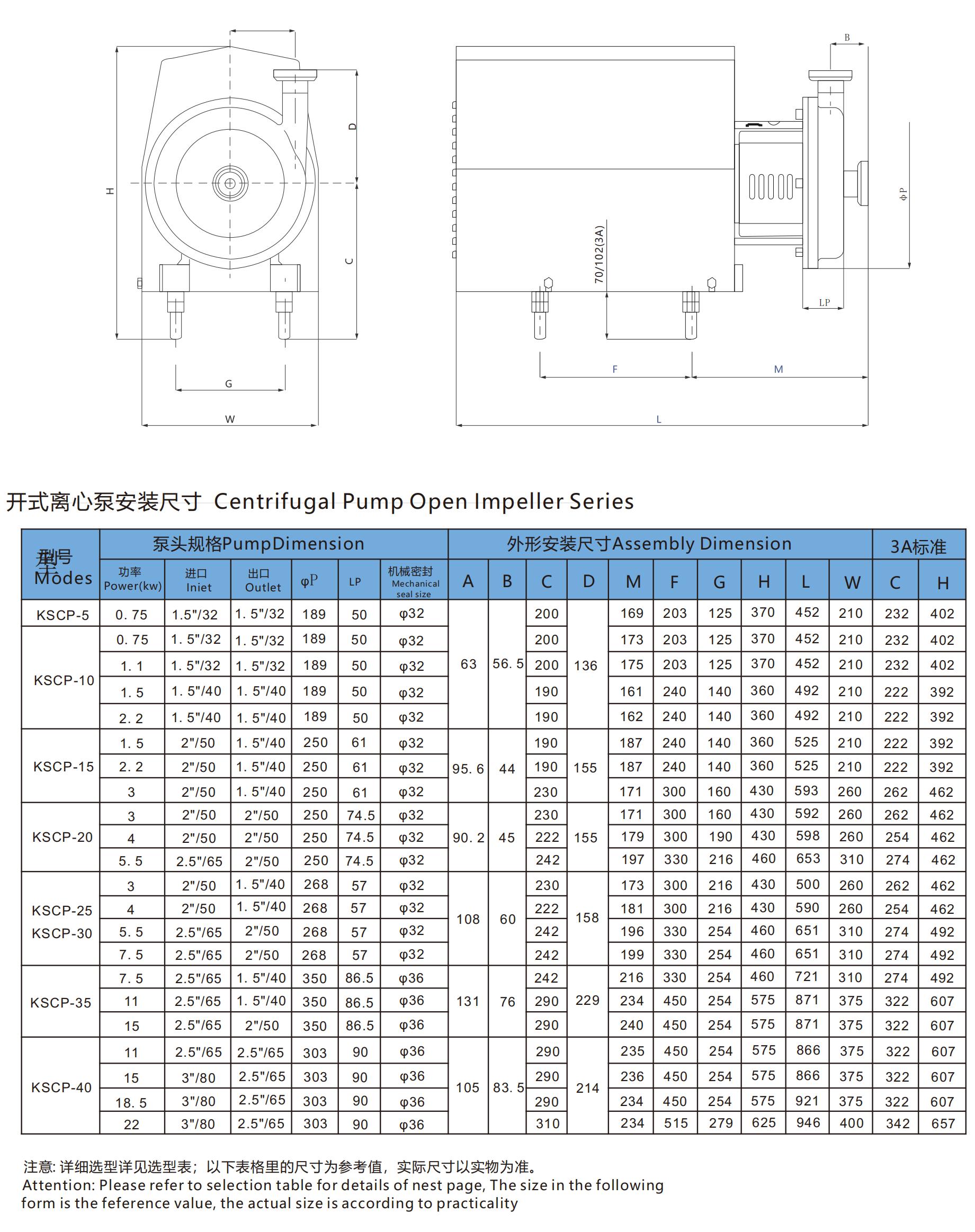

Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

| Motor type | variable frequency motor, fixed speed motor |

Frequency | 50HZ/60HZ |

Max. pressure | 7 bar |

Max. temperature | 120°C |

Material | SS304/SS316L |

| Inlet/outlet connection | Clamp, Weld, Flange |

| Inlet/outlet size | 1”-3” |

| Diaphragm | PTFE, PTFE with white back, EPDM, white EPDM, white NBR |

| Driving way | Air or Motor |

Features

● A micro-bubble separation chamber is specially designed inside the stainless steel sanitary self-priming pump. The residual bubbles are automatically separated and discharged from the system by using the density difference between liquid and bubbles.

● The surface of the stainless steel sanitary self-priming pump is specially polished and treated with liquid film affinity, so that the residual liquid forms a uniform film in the pump chamber to keep the self-priming chamber moist.

● The impeller of the stainless steel sanitary self-priming pump adopts a multi-dimensional dynamic balance adaptive structure, which can fine-tune the operating balance point in real time according to the viscosity, density or gas-liquid ratio of the conveyed liquid, reduce operating vibration and impeller eccentric wear.

● The stainless steel sanitary self-priming pump is equipped with a negative pressure fine-tuning device, which can automatically adjust the internal negative pressure according to the length of the feed pipeline or the liquid level difference, and always maintain the optimal self-priming negative pressure range.

● The stainless steel sanitary self-priming pump is designed with a special dry area channel to guide the dead corner liquid that cannot be emptied to the easy-to-discharge area to avoid long-term residual liquid retention.

● The stainless steel sanitary self-priming pump uses a special low expansion coefficient stainless steel alloy, combined with a double-end precision positioning structure. Even during high-temperature disinfection or hot material transportation, the thermal expansion of the shaft is always controlled at the micron level to maintain axial symmetry.

Application

The Stainless Steel Sanitary Motor Vertical Self Impeller Priming Centrifugal Pump is widely used in food and beverage production for transferring milk, juice, syrups, and liquid additives under hygienic conditions. It is also applied in pharmaceutical and biotechnology industries for moving purified water, solutions, and intermediates where cleanliness and reliability are essential. Additionally, it supports cosmetic and chemical processing lines requiring corrosion resistance and stable, contamination-free liquid handling.