| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless Steel High Temperature Corrosion Resistant Flange Steam Angle Seat Valve

Stainless Steel High Temperature Corrosion Resistant Flange Steam Angle Seat Valve is a durable valve designed for controlling high-temperature steam in industrial processes. Its flange connection ensures secure installation, while corrosion-resistant materials provide reliable performance under extreme thermal and chemical conditions.

Working Principles

The working principle of a Stainless Steel High Temperature Corrosion Resistant Flange Steam Angle Seat Valve is based on regulating steam flow through an angled seat using a pneumatic or manual actuator. When the actuator is engaged, the valve stem lifts the plug from the seat, allowing high-temperature steam to pass through the valve efficiently. The angled seat reduces flow resistance and ensures smooth discharge. Releasing or reversing the actuator closes the valve, pressing the plug tightly against the seat to achieve a secure seal and prevent leakage. Its corrosion-resistant stainless steel construction allows reliable operation in harsh steam environments, ensuring long-term durability and safe process control in industrial applications

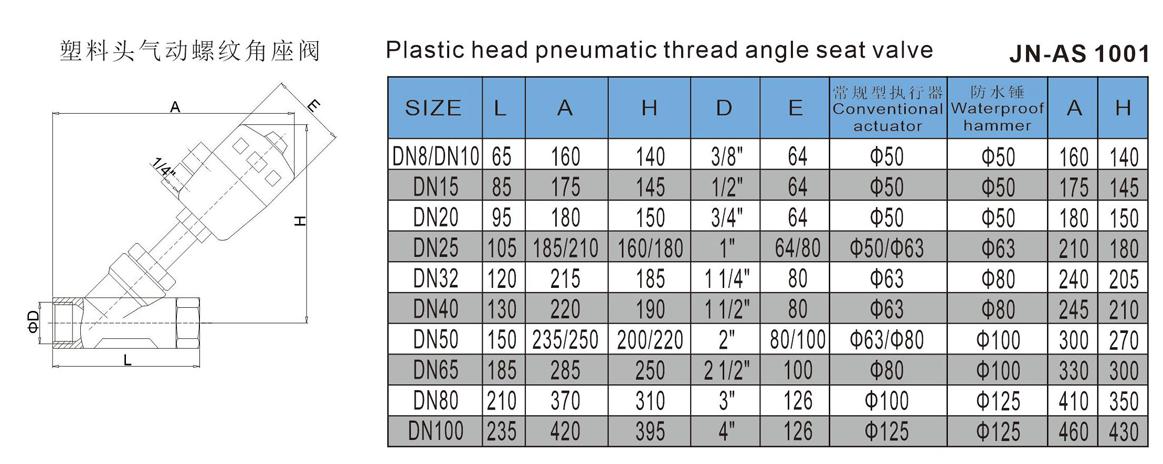

Stainless Steel Angle Seat Valve Specification Chart

Max Working Pressure | 1.6MPa |

Medium Temperature | -10℃~+180℃ |

Ambient Temperature | -10℃~+55℃ |

Body Materials | CF8M(SS316),CF8(SS304) |

Sealing Material | PTFE |

Operation | Normally Closed, Normally Open, Double-acting or Manually |

Connection End | Female, Weld,Clamp, Flange or on request |

Size Range | DN10-DN100 |

Surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Standards | DIN, SMS, ISO / IDF, BS / RJT, ASME / BPE. |

Control type | Single acting, double acting |

Features

Made from corrosion-resistant stainless steel, ensuring durability and reliable performance under high-temperature steam conditions.

Flange connection provides secure installation and easy integration into industrial piping systems.

Angle seat design allows smooth steam flow, minimizes pressure loss, and ensures efficient discharge.

Equipped with a pneumatic or manual actuator for fast, precise, and controlled valve operation.

Suitable for harsh industrial environments, supporting long-term use while maintaining safe and leak-free performance.

Application

Stainless Steel High Temperature Corrosion Resistant Flange Steam Angle Seat Valves are widely used in chemical and petrochemical industries to control high-temperature steam in reactors and heat exchangers. They are also applied in food, beverage, and pharmaceutical production for sterilization and heating processes. Their corrosion-resistant construction, flange connection, and reliable sealing make them suitable for industries requiring precise steam control, safe operation, and long-term durability under extreme temperature and chemical conditions.

Working Principles

The working principle of a Stainless Steel High Temperature Corrosion Resistant Flange Steam Angle Seat Valve is based on regulating steam flow through an angled seat using a pneumatic or manual actuator. When the actuator is engaged, the valve stem lifts the plug from the seat, allowing high-temperature steam to pass through the valve efficiently. The angled seat reduces flow resistance and ensures smooth discharge. Releasing or reversing the actuator closes the valve, pressing the plug tightly against the seat to achieve a secure seal and prevent leakage. Its corrosion-resistant stainless steel construction allows reliable operation in harsh steam environments, ensuring long-term durability and safe process control in industrial applications

Feature and Specification

Stainless Steel Angle Seat Valve Specification Chart

Max Working Pressure | 1.6MPa |

Medium Temperature | -10℃~+180℃ |

Ambient Temperature | -10℃~+55℃ |

Body Materials | CF8M(SS316),CF8(SS304) |

Sealing Material | PTFE |

Operation | Normally Closed, Normally Open, Double-acting or Manually |

Connection End | Female, Weld,Clamp, Flange or on request |

Size Range | DN10-DN100 |

Surface treatment | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Standards | DIN, SMS, ISO / IDF, BS / RJT, ASME / BPE. |

Control type | Single acting, double acting |

Features

Made from corrosion-resistant stainless steel, ensuring durability and reliable performance under high-temperature steam conditions.

Flange connection provides secure installation and easy integration into industrial piping systems.

Angle seat design allows smooth steam flow, minimizes pressure loss, and ensures efficient discharge.

Equipped with a pneumatic or manual actuator for fast, precise, and controlled valve operation.

Suitable for harsh industrial environments, supporting long-term use while maintaining safe and leak-free performance.

Application

Stainless Steel High Temperature Corrosion Resistant Flange Steam Angle Seat Valves are widely used in chemical and petrochemical industries to control high-temperature steam in reactors and heat exchangers. They are also applied in food, beverage, and pharmaceutical production for sterilization and heating processes. Their corrosion-resistant construction, flange connection, and reliable sealing make them suitable for industries requiring precise steam control, safe operation, and long-term durability under extreme temperature and chemical conditions.