| Availability: | |

|---|---|

| Quantity: | |

JN 1021

JONENG

8481804090

Stainless Steel Sanitary Manual Flow Diverter Valve For Dairy Products

The stainless steel sanitary manual flow steering valve is designed not only to change the flow direction of the fluid, but also to provide a highly controllable and pollution-free fluid management solution in a dynamic process. It can accurately switch the flow direction of the fluid between multiple pipelines, ensuring that different media can be efficiently diverted, mixed or isolated on the same production line while avoiding cross contamination. Its special internal flow channel optimization design makes fluid switching smoother, reduces turbulence and shear force, and is suitable for processes that are sensitive to fluid state, such as high-viscosity material transportation or gas-liquid mixing systems. In addition, the valve adopts a sanitary sealing system to ensure that it can maintain an ultra-low leakage rate after long-term operation. Its manual operation mode combined with visual flow direction indication is suitable for environments that require flexible adjustment of production processes, ensuring high adaptability and stability under changing process requirements.

Working Principles

The working principle of the stainless steel sanitary manual flow steering valve is based on manually manipulating the valve core position to change the flow direction of the fluid in the pipeline. First, the operator rotates the valve stem through a handle or handwheel to drive the internal valve core to adjust the angle. The valve core is usually designed with a T-type, L-type or other flow channel structure. When it rotates to different positions, the fluid channel will change to achieve fluid guidance, diversion, confluence or cutting. A high-precision sealing system is used between the valve core and the valve body to ensure that there will be no leakage or medium mixing during the switching process. In multi-channel applications, the valve core can be set in multiple fixed positions to ensure that different fluids flow accurately according to the set path. The entire process does not require additional power and relies entirely on manual operation. It is suitable for sanitary pipeline systems such as food, pharmaceuticals, dairy products, beverages, etc. that require flexible adjustment of flow direction.

The options of stainless steel sanitary manual flow steering valve include:

Valve body structure: two-way, three-way, four-way, multi-way optional.

Flow channel form: T-type, L-type, X-type and other flow channel designs.

Sealing material: EPDM, PTFE, FKM and other optional.

Connection method: quick installation (quick installation), welding, flange, etc.

Surface treatment: internal and external mirror polishing, electrolytic polishing.

Handle type: stainless steel handle, plastic handle, with locking device.

Visual indication: flow direction indication window, scale mark.

High pressure/corrosion resistant type: suitable for special media or high pressure environment.

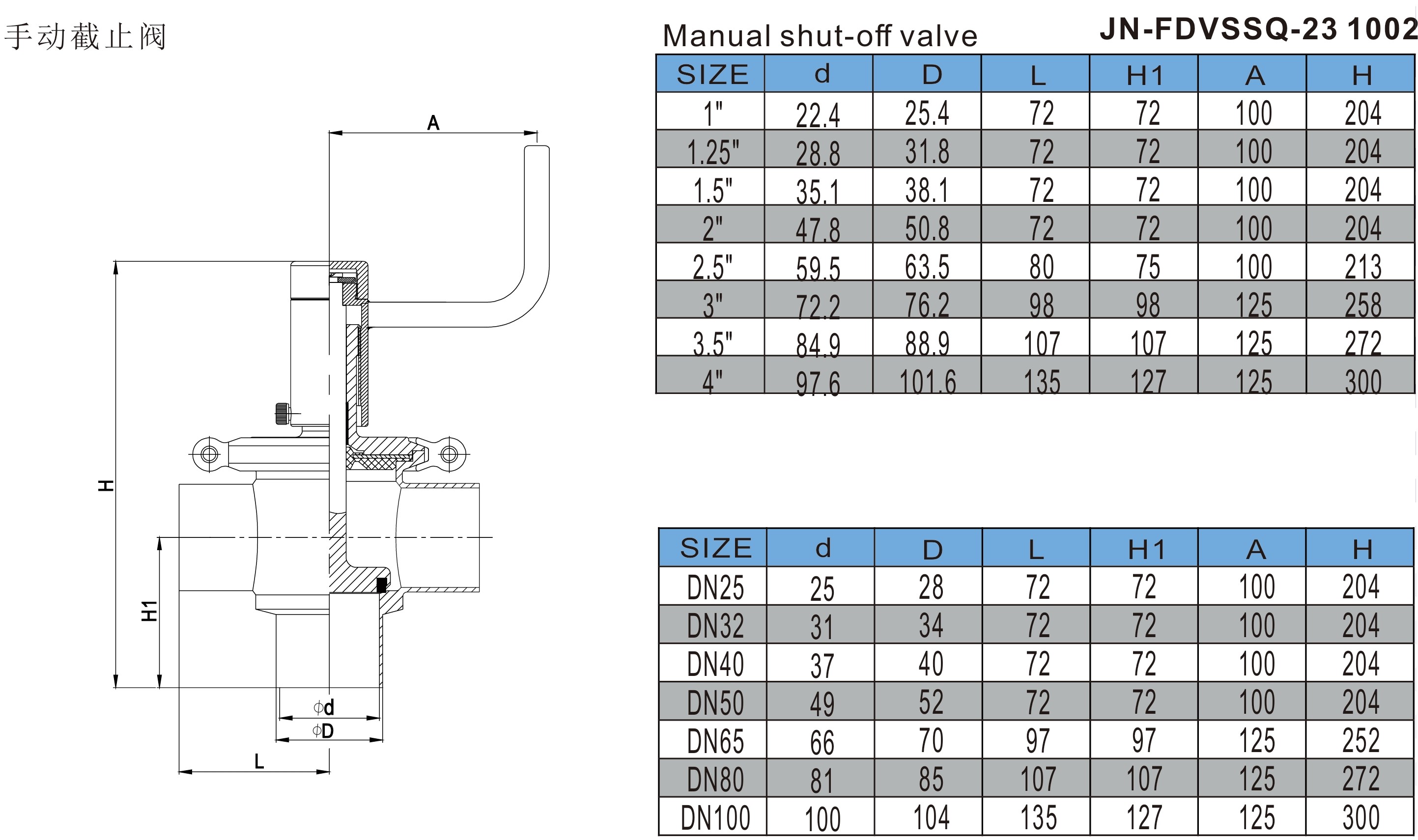

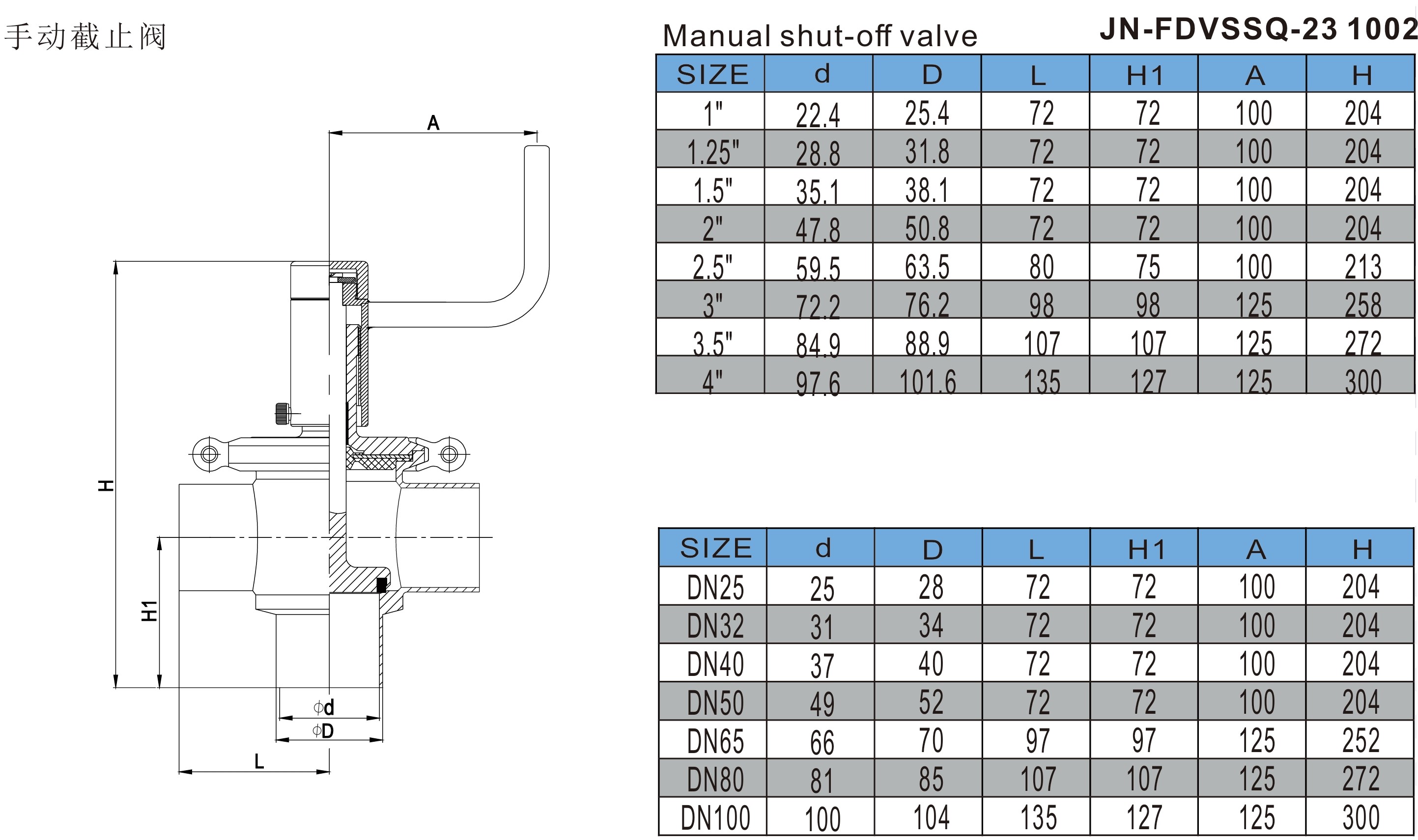

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary manual flow steering valve adopts a progressive valve core structure to reduce instantaneous pressure fluctuations when switching flow directions and avoid violent impact of the fluid.

● The stainless steel sanitary manual flow steering valve adopts a double sealing system design to synchronously seal and close unused pipe ports during the switching process to prevent residual fluid from flowing back or cross-contamination.

● The internal flow channel of the stainless steel sanitary manual flow steering valve adopts a self-draining angle design, so that the residual liquid can be quickly discharged after the fluid is switched to avoid dead corner retention.

● The stainless steel sanitary manual flow steering valve is equipped with an adjustable flow direction positioning lock to ensure that the valve core can accurately stop when switching different flow directions to avoid medium mixing caused by misoperation.

● The stainless steel sanitary manual flow steering valve reduces the impact of shear force on the fluid by optimizing the internal streamline design of the valve body.

● The stainless steel sanitary manual flow steering valve adopts an adjustable angle handle structure to make the operation more ergonomic.

Application

Stainless steel sanitary manual flow steering valves are widely used in the following industries: Food processing industry: used for flow direction switching of liquid delivery systems such as dairy products, juices, and beverages to ensure the hygiene and safety of the production process. Pharmaceutical industry: suitable for the diversion and switching of fluids in aseptic production processes such as biopharmaceuticals, injections, and vaccines to prevent contamination. Dairy industry: used for precise control and conversion of fluids such as milk and yogurt during pasteurization, homogenization and storage. Beer brewing industry: suitable for wort delivery and fermentation liquid flow control to ensure pollution-free switching of different media during the brewing process.

Working Principles

The working principle of the stainless steel sanitary manual flow steering valve is based on manually manipulating the valve core position to change the flow direction of the fluid in the pipeline. First, the operator rotates the valve stem through a handle or handwheel to drive the internal valve core to adjust the angle. The valve core is usually designed with a T-type, L-type or other flow channel structure. When it rotates to different positions, the fluid channel will change to achieve fluid guidance, diversion, confluence or cutting. A high-precision sealing system is used between the valve core and the valve body to ensure that there will be no leakage or medium mixing during the switching process. In multi-channel applications, the valve core can be set in multiple fixed positions to ensure that different fluids flow accurately according to the set path. The entire process does not require additional power and relies entirely on manual operation. It is suitable for sanitary pipeline systems such as food, pharmaceuticals, dairy products, beverages, etc. that require flexible adjustment of flow direction.

The options of stainless steel sanitary manual flow steering valve include:

Valve body structure: two-way, three-way, four-way, multi-way optional.

Flow channel form: T-type, L-type, X-type and other flow channel designs.

Sealing material: EPDM, PTFE, FKM and other optional.

Connection method: quick installation (quick installation), welding, flange, etc.

Surface treatment: internal and external mirror polishing, electrolytic polishing.

Handle type: stainless steel handle, plastic handle, with locking device.

Visual indication: flow direction indication window, scale mark.

High pressure/corrosion resistant type: suitable for special media or high pressure environment.

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary manual flow steering valve adopts a progressive valve core structure to reduce instantaneous pressure fluctuations when switching flow directions and avoid violent impact of the fluid.

● The stainless steel sanitary manual flow steering valve adopts a double sealing system design to synchronously seal and close unused pipe ports during the switching process to prevent residual fluid from flowing back or cross-contamination.

● The internal flow channel of the stainless steel sanitary manual flow steering valve adopts a self-draining angle design, so that the residual liquid can be quickly discharged after the fluid is switched to avoid dead corner retention.

● The stainless steel sanitary manual flow steering valve is equipped with an adjustable flow direction positioning lock to ensure that the valve core can accurately stop when switching different flow directions to avoid medium mixing caused by misoperation.

● The stainless steel sanitary manual flow steering valve reduces the impact of shear force on the fluid by optimizing the internal streamline design of the valve body.

● The stainless steel sanitary manual flow steering valve adopts an adjustable angle handle structure to make the operation more ergonomic.

Application

Stainless steel sanitary manual flow steering valves are widely used in the following industries: Food processing industry: used for flow direction switching of liquid delivery systems such as dairy products, juices, and beverages to ensure the hygiene and safety of the production process. Pharmaceutical industry: suitable for the diversion and switching of fluids in aseptic production processes such as biopharmaceuticals, injections, and vaccines to prevent contamination. Dairy industry: used for precise control and conversion of fluids such as milk and yogurt during pasteurization, homogenization and storage. Beer brewing industry: suitable for wort delivery and fermentation liquid flow control to ensure pollution-free switching of different media during the brewing process.