| Availability: | |

|---|---|

| Quantity: | |

This is a crucial tool for brewing and winemaking helps in transferring the liquid from fermentation vessels while maintaining the desired quality and minimizing the disturbance of sediment through rotating and adjustable design.

JONENG

8481804090

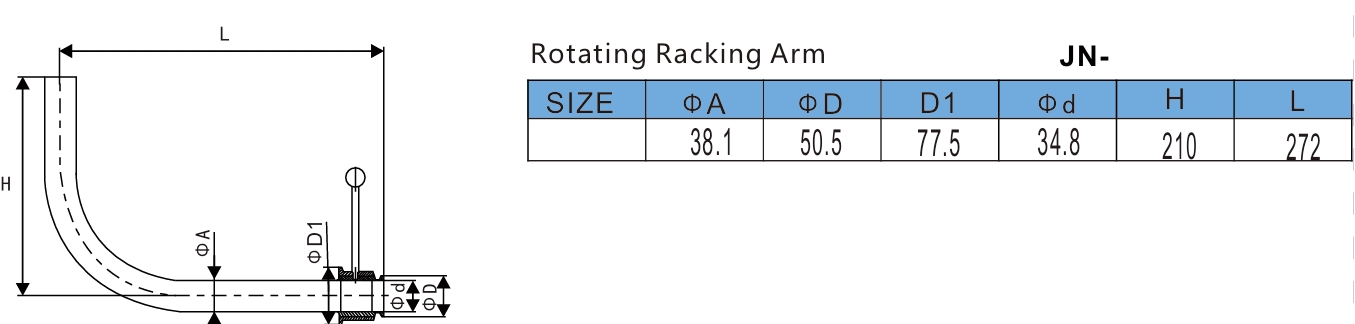

Stainless Steel Rotating Racking Arm Valve for Conical Fermentation Tanks

It is designed to install inside a fermentation vessel. It is composed of the racking arm tube, rotating mechanism, seals and gaskets, adjustment handle and connection. It works by providing the control in way that helps in transferring the fermented product and leaving the sediments into vessel without disturbing it. It is a valuable tool for quality insurance and consistency for production of beverages like beer and

Working Principles

The working principle of this arm mainly involve its ability to swirl or rotate within the fermenting vessel and allows for controlled liquid transfer and leaving the solids in the tank.

Stainless Steel Rotating Racking Arm Specification Chart

Material | AISI304 |

Size | ½ “ to 12” |

Type | tri-clover 60 °C to 90 °C racking arm |

Seals and gasket | EPDM, PTFE, silicone |

End connections | Welded, flanged, Tri-clamp |

Features

●Improved liquid clarity

●Efficiency, consistency

●Sanitation, hygiene

●Ease of operation

●Versatility, sampling and testing

Application

The primary application in brewing and winemaking industries other than these it is also used in biotechnology, pharmaceuticals and food and dairy processing industries.

Working Principles

The working principle of this arm mainly involve its ability to swirl or rotate within the fermenting vessel and allows for controlled liquid transfer and leaving the solids in the tank.

Feature and Specification

Stainless Steel Rotating Racking Arm Specification Chart

Material | AISI304 |

Size | ½ “ to 12” |

Type | tri-clover 60 °C to 90 °C racking arm |

Seals and gasket | EPDM, PTFE, silicone |

End connections | Welded, flanged, Tri-clamp |

Features

●Improved liquid clarity

●Efficiency, consistency

●Sanitation, hygiene

●Ease of operation

●Versatility, sampling and testing

Application

The primary application in brewing and winemaking industries other than these it is also used in biotechnology, pharmaceuticals and food and dairy processing industries.