| Availability: | |

|---|---|

| Quantity: | |

JN SV 1076

JONENG

8481804090

Stainless Steel Sanitary Ball Pressure Safety Relief Valve

The purpose of the design of the stainless steel sanitary ball safety valve is to provide a safety protection device that can quickly respond to pressure changes and completely eliminate medium residues and bacterial growth in an industrial environment with ultra-high sanitation standards. Its uniqueness lies in the use of a spherical valve core and a precisely polished flow channel design to ensure that the valve can be opened and closed instantly under high pressure or sudden pressure changes to prevent the system from overpressure or vacuum damage to the equipment. At the same time, its zero dead angle structure and electrolytic polished surface allow the medium to flow without residue, which is particularly suitable for fluids that are easy to crystallize, have high viscosity or require sterility, such as biological agents, high-purity chemicals or food raw materials. In addition, its material and sealing design can withstand corrosive media and high temperature and high pressure environments to ensure long-term stable operation. This valve not only meets safety requirements, but also takes into account hygiene, efficiency and reliability, making it an ideal choice in the field of high-end manufacturing.

Working Principles

The working principle of the stainless steel sanitary ball safety valve is based on pressure control. When the pressure in the system exceeds the set value, the valve automatically opens to release excess pressure to prevent the pipeline from bursting. First, the spherical seat of the valve is in close contact with the sealing ring and remains closed. When the pipeline pressure increases, the valve spring or pneumatic drive is pushed to force the spherical valve seat to move away, forming a fluid outlet, and the pressure is quickly released. After the release, the system pressure drops, and the valve relies on the spring or automatic reset device to return to its original position to ensure that the system returns to normal pressure.

The options for the stainless steel sanitary ball safety valve include:

Pressure range: A variety of preset pressure values are available to meet different system requirements.

Connection method: thread, clamp, welding or flange connection.

Material: 304 or 316L stainless steel to meet different corrosion resistance requirements.

Sealing material: EPDM, FKM, PTFE, etc., to adapt to different media and temperatures.

Surface treatment: electrolytic polishing or mirror polishing to improve the hygiene level.

Caliber specifications: a variety of sizes are available to adapt to different pipe diameters.

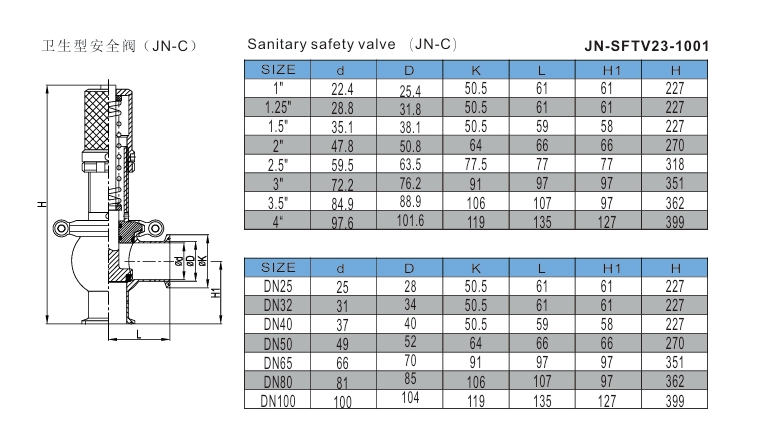

Specification Chart

Type | Ball type, line type |

Working Pressure | 0bar-10bar |

Working Temperature | -10°C ~ +121°C |

Connection end | welded,clamped , threaded, union type |

Connection Standards | DIN, SMS, 3A, ISO |

Size | 1”-4”, DN25-DN100 |

Material | SS304, SS316L from solid bar raw material |

| With internal finishing Ra16<0.4micron | |

Surface finish | Sand blasting type, or mirror type |

Seal Material | FDA approved EPDM, VITION, NBR, SILICOME |

| Adjusting pressure | 0.5bar/unit |

| Manually adjustable to keep the system safety | |

Lock can be available for settling the relief pressure | |

Features

● The stainless steel sanitary ball safety valve adopts a unique fluid flow channel design, which effectively reduces fluid turbulence during valve opening and reduces operating noise.

● The design of the stainless steel sanitary ball safety valve has no dead angle, ensuring the complete discharge of the fluid and avoiding material residue, thereby ensuring hygiene requirements, and is suitable for food, pharmaceutical and other industries.

● The stainless steel sanitary ball safety valve can work stably in high temperature environments, especially suitable for industrial systems controlled by high temperature fluids or steam, and has strong resistance to high temperature corrosion.

● The spring and pneumatic drive system of the stainless steel sanitary ball safety valve cooperate to achieve rapid response, effectively reducing the reaction time when the pressure suddenly increases, and preventing the equipment from being damaged due to excessive pressure.

● The stainless steel sanitary ball safety valve is equipped with pneumatic and manual control methods, which can automatically respond to system pressure changes and intervene through manual adjustment when necessary.

● The stainless steel sanitary ball safety valve adopts an anti-seismic design inside, which can effectively reduce the impact of system vibration on the valve and improve the stability and reliability of the valve.

Application

Stainless steel sanitary ball safety valves are widely used in the following industries: Food industry: used for fluid delivery of beverages, dairy products, condiments, etc., to ensure high hygiene standards. Pharmaceutical industry: suitable for medium transmission such as liquid medicine, vaccines, sterile water, etc., to meet GMP requirements. Bioengineering: used for high-cleanliness fluid control such as cell culture fluid and culture medium. Cosmetic industry: transport emulsions, essences and other products to ensure no pollution and high purity. Chemical industry: handle corrosive chemicals and high-purity solvents, with strong corrosion resistance. Semiconductor industry: used for ultrapure water and high-purity gas delivery to meet clean room requirements.

Working Principles

The working principle of the stainless steel sanitary ball safety valve is based on pressure control. When the pressure in the system exceeds the set value, the valve automatically opens to release excess pressure to prevent the pipeline from bursting. First, the spherical seat of the valve is in close contact with the sealing ring and remains closed. When the pipeline pressure increases, the valve spring or pneumatic drive is pushed to force the spherical valve seat to move away, forming a fluid outlet, and the pressure is quickly released. After the release, the system pressure drops, and the valve relies on the spring or automatic reset device to return to its original position to ensure that the system returns to normal pressure.

The options for the stainless steel sanitary ball safety valve include:

Pressure range: A variety of preset pressure values are available to meet different system requirements.

Connection method: thread, clamp, welding or flange connection.

Material: 304 or 316L stainless steel to meet different corrosion resistance requirements.

Sealing material: EPDM, FKM, PTFE, etc., to adapt to different media and temperatures.

Surface treatment: electrolytic polishing or mirror polishing to improve the hygiene level.

Caliber specifications: a variety of sizes are available to adapt to different pipe diameters.

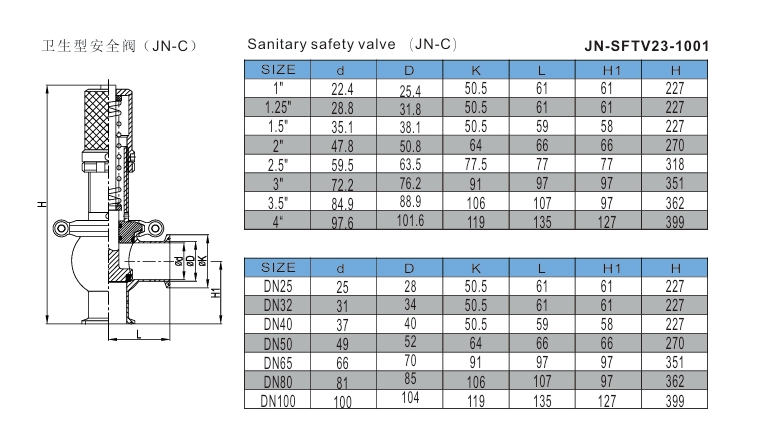

Specification Chart

Type | Ball type, line type |

Working Pressure | 0bar-10bar |

Working Temperature | -10°C ~ +121°C |

Connection end | welded,clamped , threaded, union type |

Connection Standards | DIN, SMS, 3A, ISO |

Size | 1”-4”, DN25-DN100 |

Material | SS304, SS316L from solid bar raw material |

| With internal finishing Ra16<0.4micron | |

Surface finish | Sand blasting type, or mirror type |

Seal Material | FDA approved EPDM, VITION, NBR, SILICOME |

| Adjusting pressure | 0.5bar/unit |

| Manually adjustable to keep the system safety | |

Lock can be available for settling the relief pressure | |

Features

● The stainless steel sanitary ball safety valve adopts a unique fluid flow channel design, which effectively reduces fluid turbulence during valve opening and reduces operating noise.

● The design of the stainless steel sanitary ball safety valve has no dead angle, ensuring the complete discharge of the fluid and avoiding material residue, thereby ensuring hygiene requirements, and is suitable for food, pharmaceutical and other industries.

● The stainless steel sanitary ball safety valve can work stably in high temperature environments, especially suitable for industrial systems controlled by high temperature fluids or steam, and has strong resistance to high temperature corrosion.

● The spring and pneumatic drive system of the stainless steel sanitary ball safety valve cooperate to achieve rapid response, effectively reducing the reaction time when the pressure suddenly increases, and preventing the equipment from being damaged due to excessive pressure.

● The stainless steel sanitary ball safety valve is equipped with pneumatic and manual control methods, which can automatically respond to system pressure changes and intervene through manual adjustment when necessary.

● The stainless steel sanitary ball safety valve adopts an anti-seismic design inside, which can effectively reduce the impact of system vibration on the valve and improve the stability and reliability of the valve.

Application

Stainless steel sanitary ball safety valves are widely used in the following industries: Food industry: used for fluid delivery of beverages, dairy products, condiments, etc., to ensure high hygiene standards. Pharmaceutical industry: suitable for medium transmission such as liquid medicine, vaccines, sterile water, etc., to meet GMP requirements. Bioengineering: used for high-cleanliness fluid control such as cell culture fluid and culture medium. Cosmetic industry: transport emulsions, essences and other products to ensure no pollution and high purity. Chemical industry: handle corrosive chemicals and high-purity solvents, with strong corrosion resistance. Semiconductor industry: used for ultrapure water and high-purity gas delivery to meet clean room requirements.