| Availability: | |

|---|---|

| Quantity: | |

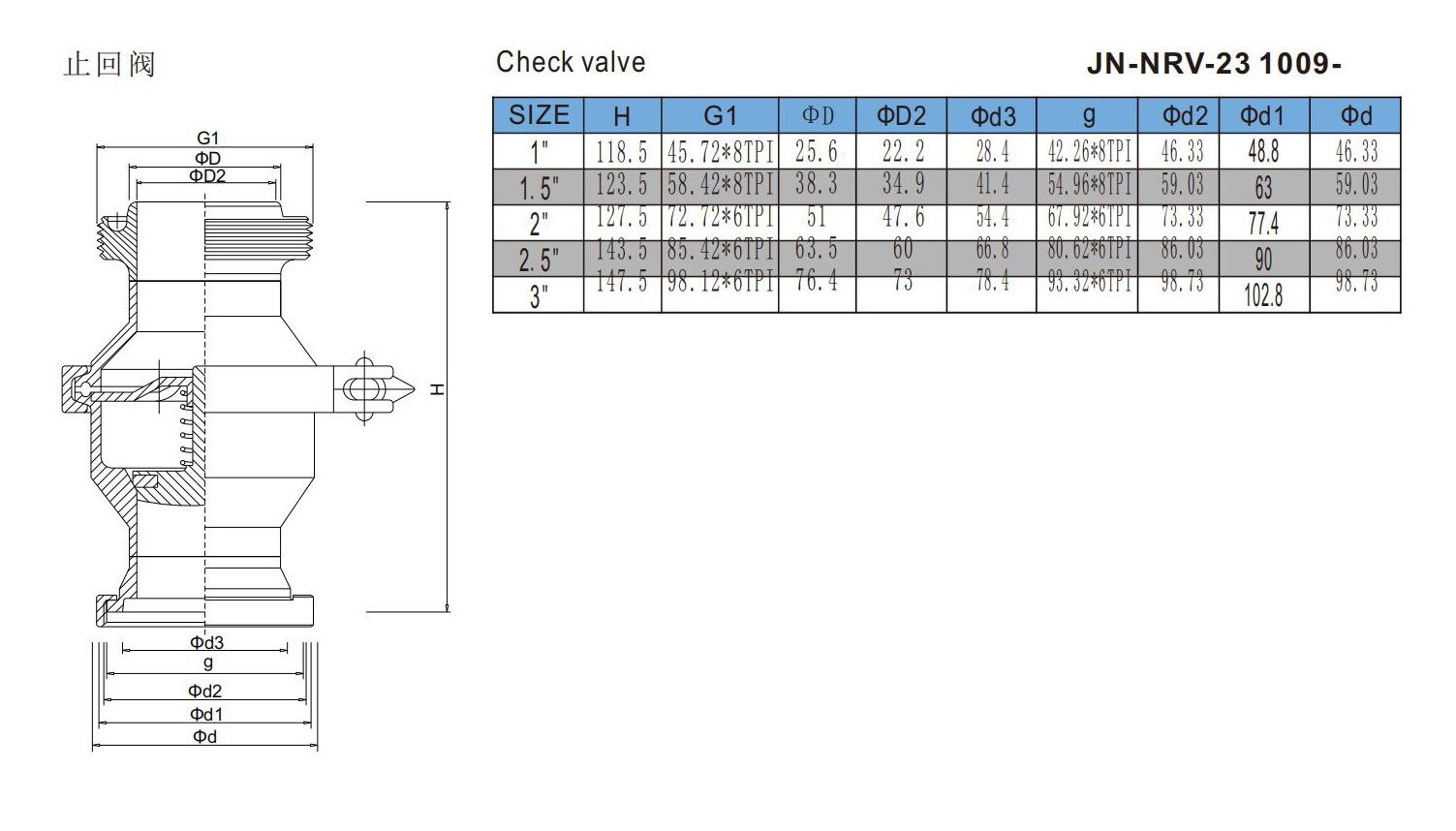

JN-NRV-23 1009

JONENG

8481804090

Stainless Steel Sanitary Butt Welding NRV Check Valve

The design purpose of the stainless steel sanitary check valve is to ensure the one-way flow of liquid or gas in the fluid system under a strict sanitary environment, prevent backflow and contamination, ensure the normal operation of the system, protect equipment and improve production efficiency. It is especially suitable for industries such as food, beverages, and pharmaceuticals that require high hygiene standards. It can effectively avoid cross-contamination of fluids and ensure product quality and safety.

Working Principles

The working principle of the stainless steel sanitary check valve is to use the pressure of the fluid to control the opening and closing of the valve disc to ensure that the fluid can only flow in one direction and prevent backflow. The specific principle is as follows: When the fluid flows into the pipeline and flows forward, the pressure of the fluid pushes the valve disc to open, allowing the fluid to pass through the valve smoothly. When the fluid stops flowing or reverses, the valve disc automatically closes through the action of the spring, gravity or valve body design to prevent the fluid from flowing back.

Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries | |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred | |

The min. pressure difference is 0.08bar to open the valve | |

Flow direction is from the bottom to the top side only | |

Precision machined body, stem, disc, free draining | |

Disc tapered for smooth body and reduce draining | |

The check valves can not be used for sticky ,adhesive, viscous products. | |

Features

● The valve body adopts a smooth inner and outer surface design. The surface of the valve body, valve disc and other internal parts is smooth and without protrusions, which reduces the accumulation of bacteria and dirt.

● It adopts high-quality stainless steel (such as 304, 316L), which has excellent corrosion resistance and can cope with the challenges of chemicals, acid and alkali liquids and high temperature environments.

● Equipped with high-precision sealing gaskets (such as EPDM, silicone) to ensure the sealing of the valve and avoid liquid or gas leakage.

● There is a fast-response valve disc (such as spring-type or gravity-type design) that can be closed quickly to prevent backflow.

● All parts are designed to be easy to clean, the valve body is smooth and has no dead corners, and the seals are food-grade materials to prevent cross-contamination.

● The design focuses on the flowability of fluid passing through, has low fluid resistance, and can support a larger flow rate.

● Improves cleaning efficiency, avoids the risk of bacterial growth, meets strict hygiene standards (such as FDA, EHEDG, 3A, etc.), and ensures the purity of the product.

● It improves the service life of the equipment, reduces equipment failures caused by corrosion, is suitable for industries requiring high corrosion tolerance, and reduces maintenance and replacement frequency.

● It provides efficient sealing, prevents any form of leakage or backflow, improves system pressure stability, and reduces possible equipment damage.

● It prevents fluid backflow, quickly restores the normal direction of the fluid, avoids system pressure fluctuations, improves system response speed, and ensures the stability of fluid flow.

● It ensures hygienic cleaning, does not leave residues or contaminants, can effectively avoid cross contamination, and ensure product quality and safety.

● It reduces the pressure loss of the fluid inside the valve, improves the circulation efficiency and overall performance of the system, and adapts to more flow requirements.

Application

Stainless steel sanitary check valves are widely used in the following fields: Food and beverage industry: prevent liquid backflow to ensure that the product is not contaminated. Pharmaceutical industry: avoid liquid backflow to ensure the purity of the drug. Cosmetic industry: prevent finished liquid backflow to maintain product quality. Water treatment industry: prevent water pollution and ensure unidirectional water flow. Chemical industry: prevent chemical backflow to ensure system safety.

Working Principles

The working principle of the stainless steel sanitary check valve is to use the pressure of the fluid to control the opening and closing of the valve disc to ensure that the fluid can only flow in one direction and prevent backflow. The specific principle is as follows: When the fluid flows into the pipeline and flows forward, the pressure of the fluid pushes the valve disc to open, allowing the fluid to pass through the valve smoothly. When the fluid stops flowing or reverses, the valve disc automatically closes through the action of the spring, gravity or valve body design to prevent the fluid from flowing back.

Feature and Specification

Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries | |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred | |

The min. pressure difference is 0.08bar to open the valve | |

Flow direction is from the bottom to the top side only | |

Precision machined body, stem, disc, free draining | |

Disc tapered for smooth body and reduce draining | |

The check valves can not be used for sticky ,adhesive, viscous products. | |

Features

● The valve body adopts a smooth inner and outer surface design. The surface of the valve body, valve disc and other internal parts is smooth and without protrusions, which reduces the accumulation of bacteria and dirt.

● It adopts high-quality stainless steel (such as 304, 316L), which has excellent corrosion resistance and can cope with the challenges of chemicals, acid and alkali liquids and high temperature environments.

● Equipped with high-precision sealing gaskets (such as EPDM, silicone) to ensure the sealing of the valve and avoid liquid or gas leakage.

● There is a fast-response valve disc (such as spring-type or gravity-type design) that can be closed quickly to prevent backflow.

● All parts are designed to be easy to clean, the valve body is smooth and has no dead corners, and the seals are food-grade materials to prevent cross-contamination.

● The design focuses on the flowability of fluid passing through, has low fluid resistance, and can support a larger flow rate.

● Improves cleaning efficiency, avoids the risk of bacterial growth, meets strict hygiene standards (such as FDA, EHEDG, 3A, etc.), and ensures the purity of the product.

● It improves the service life of the equipment, reduces equipment failures caused by corrosion, is suitable for industries requiring high corrosion tolerance, and reduces maintenance and replacement frequency.

● It provides efficient sealing, prevents any form of leakage or backflow, improves system pressure stability, and reduces possible equipment damage.

● It prevents fluid backflow, quickly restores the normal direction of the fluid, avoids system pressure fluctuations, improves system response speed, and ensures the stability of fluid flow.

● It ensures hygienic cleaning, does not leave residues or contaminants, can effectively avoid cross contamination, and ensure product quality and safety.

● It reduces the pressure loss of the fluid inside the valve, improves the circulation efficiency and overall performance of the system, and adapts to more flow requirements.

Application

Stainless steel sanitary check valves are widely used in the following fields: Food and beverage industry: prevent liquid backflow to ensure that the product is not contaminated. Pharmaceutical industry: avoid liquid backflow to ensure the purity of the drug. Cosmetic industry: prevent finished liquid backflow to maintain product quality. Water treatment industry: prevent water pollution and ensure unidirectional water flow. Chemical industry: prevent chemical backflow to ensure system safety.