| Availability: | |

|---|---|

| Quantity: | |

Stainless Steel Twin Rotor Valve A metering valve is a precise flow control device used to precisely regulate the flow of liquids, gases or slurries in industrial systems. It features two rotors, usually made of stainless steel, that rotate within the valve body to control the passage of the fluid. This twin rotor design allows for highly accurate flow measurement and consistent dosing, making it ideal for applications where precision is critical.

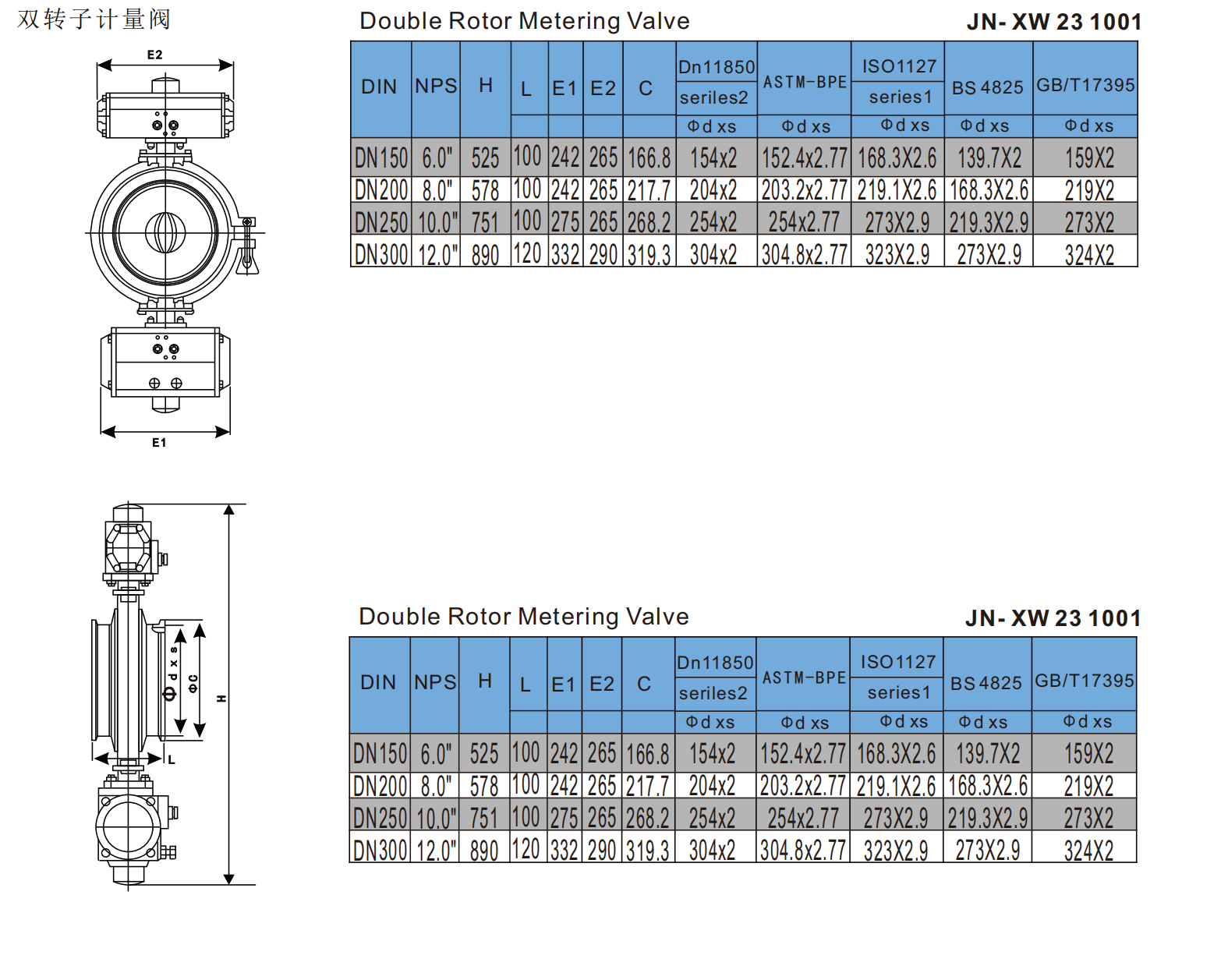

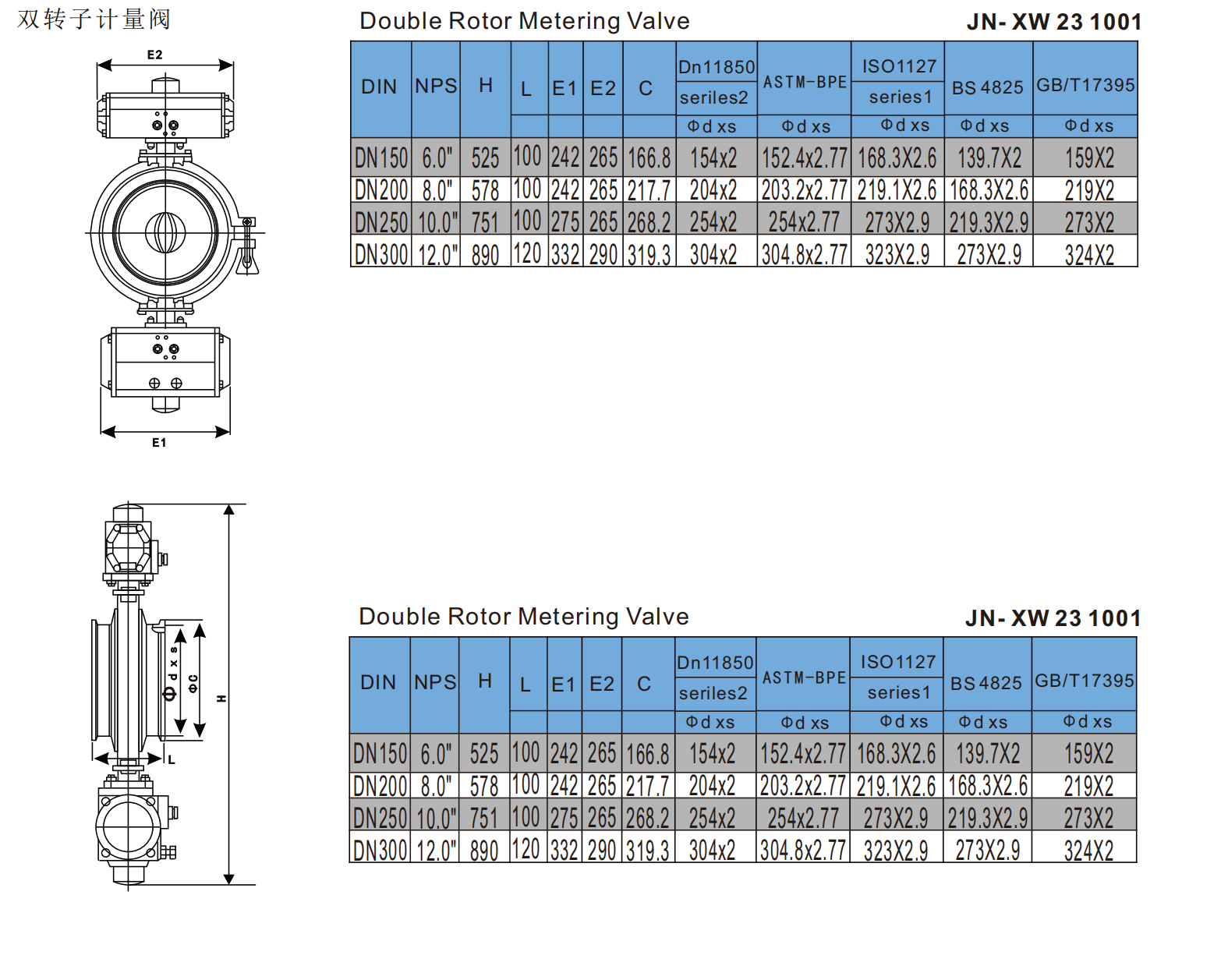

JN-XW 23 1001

JONENG

8421219990

Stainless Steel Sanitary Dual Vane Rotary Dosing Valve

Stainless Steel Twin Rotor Valve Metering Valve is a specialized valve used for precise flow control and measurement of liquids, gases, or slurries in industrial applications. This valve featues a twin rotor mechanism where the rotors work together in a complementary manner to manage fluid flow, providing fine adjustment of flow. The stainless steel construction ensures that the valve can withstand harsh conditions, including exposure to corrosive chemicals, high temperatures, and high pressure environments.

Working Principles

The operating principle of the stainless steel twin rotor metering valve is based on the controlled rotation of two interlocked rotors to precisely regulate the flow of liquids, gases or slurries. As the rotors rotate, they capture a fixed volume of fluid between their cavities. The rotation moves the fluid from the inlet to the outlet in a controlled, consistent manner. The flow rate is proportional to the speed of the rotor rotation, allowing for precise metering.

Stainless Steel Metering Valve Specification Chart

Sizes available | 3 "-16" |

Max pressure | up to 10 bar |

End connection | Flanged, threaded, clamped |

Material | AISI316L OR AISI304L |

Seals | Silicone, Viton, PTFE, EPDM |

Standard | Manual or Pneumatic |

Temperature range | 3A, SMS, ISO |

Feature

● Precision Flow Control: Provides highly accurate and consistent fluid metering by using two interlocking rotors.

● Durability: The valve is made of stainless steel.

● Leak-free Operation: The dual rotor mechanism ensures a tight seal.

● High Viscosity Handling: Capable of handling viscous liquids, slurries, and abrasive fluids.

● Easy Maintenance: Stainless steel construction is easy to clean and maintain.

● Versatility: Suitable for use in a wide range of industries.

● Compact and Efficient Design: Provides efficient fluid flow control in a compact design.

● High Temperature and Pressure Resistance: Stainless steel construction enables the valve to withstand high temperatures and pressures.

Application

Stainless steel twin rotor metering valves are widely used in industries that require precise fluid control and metering. Common applications include chemical processing, pharmaceutical industry, food and beverage industry, oil and gas industry, water treatment. Their versatility makes them suitable for any application that requires high precision and high reliability fluid handling.

Working Principles

The operating principle of the stainless steel twin rotor metering valve is based on the controlled rotation of two interlocked rotors to precisely regulate the flow of liquids, gases or slurries. As the rotors rotate, they capture a fixed volume of fluid between their cavities. The rotation moves the fluid from the inlet to the outlet in a controlled, consistent manner. The flow rate is proportional to the speed of the rotor rotation, allowing for precise metering.

Specification

Stainless Steel Metering Valve Specification Chart

Sizes available | 3 "-16" |

Max pressure | up to 10 bar |

End connection | Flanged, threaded, clamped |

Material | AISI316L OR AISI304L |

Seals | Silicone, Viton, PTFE, EPDM |

Standard | Manual or Pneumatic |

Temperature range | 3A, SMS, ISO |

Feature

● Precision Flow Control: Provides highly accurate and consistent fluid metering by using two interlocking rotors.

● Durability: The valve is made of stainless steel.

● Leak-free Operation: The dual rotor mechanism ensures a tight seal.

● High Viscosity Handling: Capable of handling viscous liquids, slurries, and abrasive fluids.

● Easy Maintenance: Stainless steel construction is easy to clean and maintain.

● Versatility: Suitable for use in a wide range of industries.

● Compact and Efficient Design: Provides efficient fluid flow control in a compact design.

● High Temperature and Pressure Resistance: Stainless steel construction enables the valve to withstand high temperatures and pressures.

Application

Stainless steel twin rotor metering valves are widely used in industries that require precise fluid control and metering. Common applications include chemical processing, pharmaceutical industry, food and beverage industry, oil and gas industry, water treatment. Their versatility makes them suitable for any application that requires high precision and high reliability fluid handling.