| Availability: | |

|---|---|

| Quantity: | |

JONENG

7307290000

Stainless Steel Sanitary EPDM Mirror Polished Joint Complete Set

The stainless steel sanitary union set is designed for high-cleanliness fluid transmission systems to achieve fast disassembly and assembly, no dead corner cleaning and pollution-free transmission. Its high polishing or electrolytic polishing surface treatment ensures smoothness and no residue, meets 3A, DIN and other hygiene standards, and is suitable for sterile environments. Through the precise coordination of the clamp, sealing ring and union, the sealing and durability are ensured, meeting the stringent requirements of the food, pharmaceutical, bioengineering and chemical industries for hygiene, efficiency and maintenance convenience.

Working Principles

The working principle of the whole set of stainless steel sanitary union is based on its quick disassembly and sealing design. The two unions are tightly connected by the clamp to ensure the alignment of the interface. The built-in sealing ring (such as EPDM, silicone or PTFE) forms a tight seal under pressure to prevent fluid leakage. The high polishing or electrolytic polishing surface treatment ensures no dead angle and is easy to clean and sterilize. The whole process realizes efficient and hygienic fluid transmission, which is suitable for rapid maintenance and cleaning needs in a sterile environment.

The options of the whole set of stainless steel sanitary union include:

Material of sealing ring: EPDM, PTFE, Viton, etc.

Connection method: clamp type, threaded type, flange type, quick release type.

Size: a variety of pipe diameters are available.

Surface treatment: mirror polishing, brushed treatment.

Pressure resistance level: different pressure levels can be selected according to needs.

Additional functions: built-in flow control valve, temperature monitoring, etc.

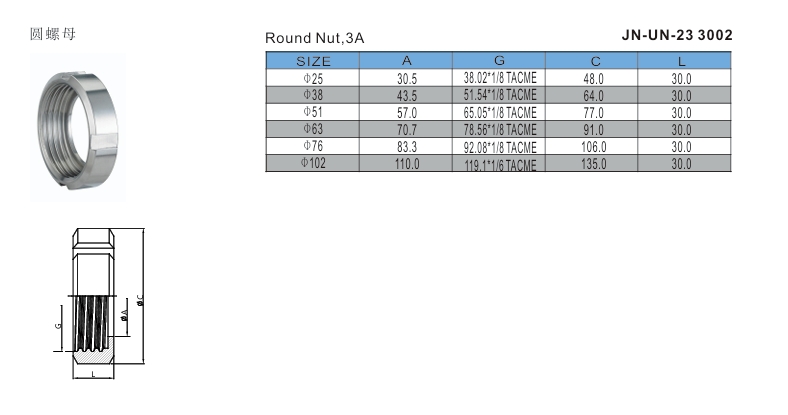

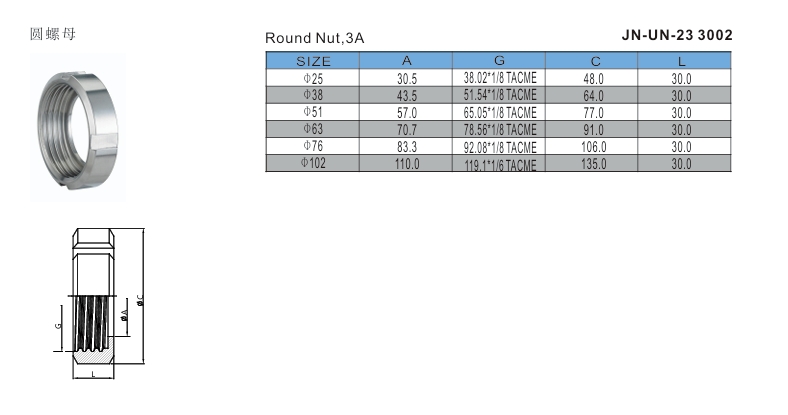

Specification Chart

Size | ½ “ to 6” |

Material | SS304, SS316 |

Gaskets or seals | Silicone, PTFE, EPDM, viton |

Pressure | - 6 to 40 bars |

Temperature | -40C to 150C |

Standard | SMS,DIN, 3A,RJT,BSM,IDF.. |

Features

● The stainless steel sanitary joint set adopts self-adjusting sealing technology. When the temperature and pressure change, the sealing ring can automatically adjust the compression force.

● The surface of the stainless steel sanitary joint set adopts a multi-layer composite anti-corrosion coating, which can effectively prevent the corrosion of corrosive liquids such as acids and alkalis on the joints.

● The stainless steel sanitary joint set adopts a sealing ring made of a new antioxidant material, which can maintain elasticity and sealing in a high-temperature oxidation environment.

● The stainless steel sanitary joint set is equipped with a double locking system inside and outside, providing double safety protection to prevent the joint from falling off under high pressure.

● The stainless steel sanitary joint set adopts innovative quick disassembly technology, so that the joint can be quickly disassembled without any tools.

● The stainless steel sanitary joint set effectively disperses the instantaneous high-pressure fluctuations in the pipeline and reduces pressure shocks through the special inner wall structure design.

Application

The complete set of stainless steel sanitary joints is widely used in the following industries: Food industry: connection of beverage and dairy production equipment. Pharmaceutical industry: pollution-free transmission of drug production. Bioengineering: connection of high-cleanliness fluid system. Chemical industry: connection of corrosion-resistant chemical pipelines. Cosmetic industry: production and transmission of hygienic and safe products.

Working Principles

The working principle of the whole set of stainless steel sanitary union is based on its quick disassembly and sealing design. The two unions are tightly connected by the clamp to ensure the alignment of the interface. The built-in sealing ring (such as EPDM, silicone or PTFE) forms a tight seal under pressure to prevent fluid leakage. The high polishing or electrolytic polishing surface treatment ensures no dead angle and is easy to clean and sterilize. The whole process realizes efficient and hygienic fluid transmission, which is suitable for rapid maintenance and cleaning needs in a sterile environment.

The options of the whole set of stainless steel sanitary union include:

Material of sealing ring: EPDM, PTFE, Viton, etc.

Connection method: clamp type, threaded type, flange type, quick release type.

Size: a variety of pipe diameters are available.

Surface treatment: mirror polishing, brushed treatment.

Pressure resistance level: different pressure levels can be selected according to needs.

Additional functions: built-in flow control valve, temperature monitoring, etc.

Specification Chart

Size | ½ “ to 6” |

Material | SS304, SS316 |

Gaskets or seals | Silicone, PTFE, EPDM, viton |

Pressure | - 6 to 40 bars |

Temperature | -40C to 150C |

Standard | SMS,DIN, 3A,RJT,BSM,IDF.. |

Features

● The stainless steel sanitary joint set adopts self-adjusting sealing technology. When the temperature and pressure change, the sealing ring can automatically adjust the compression force.

● The surface of the stainless steel sanitary joint set adopts a multi-layer composite anti-corrosion coating, which can effectively prevent the corrosion of corrosive liquids such as acids and alkalis on the joints.

● The stainless steel sanitary joint set adopts a sealing ring made of a new antioxidant material, which can maintain elasticity and sealing in a high-temperature oxidation environment.

● The stainless steel sanitary joint set is equipped with a double locking system inside and outside, providing double safety protection to prevent the joint from falling off under high pressure.

● The stainless steel sanitary joint set adopts innovative quick disassembly technology, so that the joint can be quickly disassembled without any tools.

● The stainless steel sanitary joint set effectively disperses the instantaneous high-pressure fluctuations in the pipeline and reduces pressure shocks through the special inner wall structure design.

Application

The complete set of stainless steel sanitary joints is widely used in the following industries: Food industry: connection of beverage and dairy production equipment. Pharmaceutical industry: pollution-free transmission of drug production. Bioengineering: connection of high-cleanliness fluid system. Chemical industry: connection of corrosion-resistant chemical pipelines. Cosmetic industry: production and transmission of hygienic and safe products.