| Availability: | |

|---|---|

| Quantity: | |

JN-BV 1008

JONENG

8481804090

Stainless Steel Sanitary EPDM Welded Duckbill Manual Butterfly Valve

The stainless steel sanitary welded duckbill manual butterfly valve is designed to provide an efficient and reliable fluid control solution, especially for industries with strict hygiene requirements. It uses a duckbill sealing design to ensure no leakage in high temperature, high pressure and corrosive environments, and ensure the stability and hygiene of the pipeline system. The valve adopts a welding connection, which reduces the risk of leakage that may be caused by traditional connection methods. It is suitable for precise flow control in industries such as food, pharmaceuticals, beverages, etc., meets sanitary standards such as GMP, and ensures that the fluid is not contaminated when flowing in the pipeline.

Working Principles

The working principle of the stainless steel sanitary welded duckbill manual butterfly valve is to control the flow of fluid based on the rotation of the valve disc. When the valve stem is manually operated, the valve disc rotates around its axis. Its key feature is the "duckbill seal design". A duckbill seal structure is used between the edge of the valve disc and the pipe. When the valve is fully closed, the valve disc and the valve body are tightly sealed to ensure that the fluid does not leak. Using a stainless steel sanitary welded duckbill manual butterfly valve can ensure a stable flow of fluid and avoid system failures caused by flow fluctuations.

The options of the stainless steel sanitary welded duckbill manual butterfly valve include:

Valve body material: 304 stainless steel, 316L stainless steel.

Sealing material: EPDM, PTFE, silicone.

Connection method: welding connection.

Valve disc type: flat valve disc, duckbill valve disc.

Operation method: manual operation, with locking device.

Size selection: customized according to the pipe diameter.

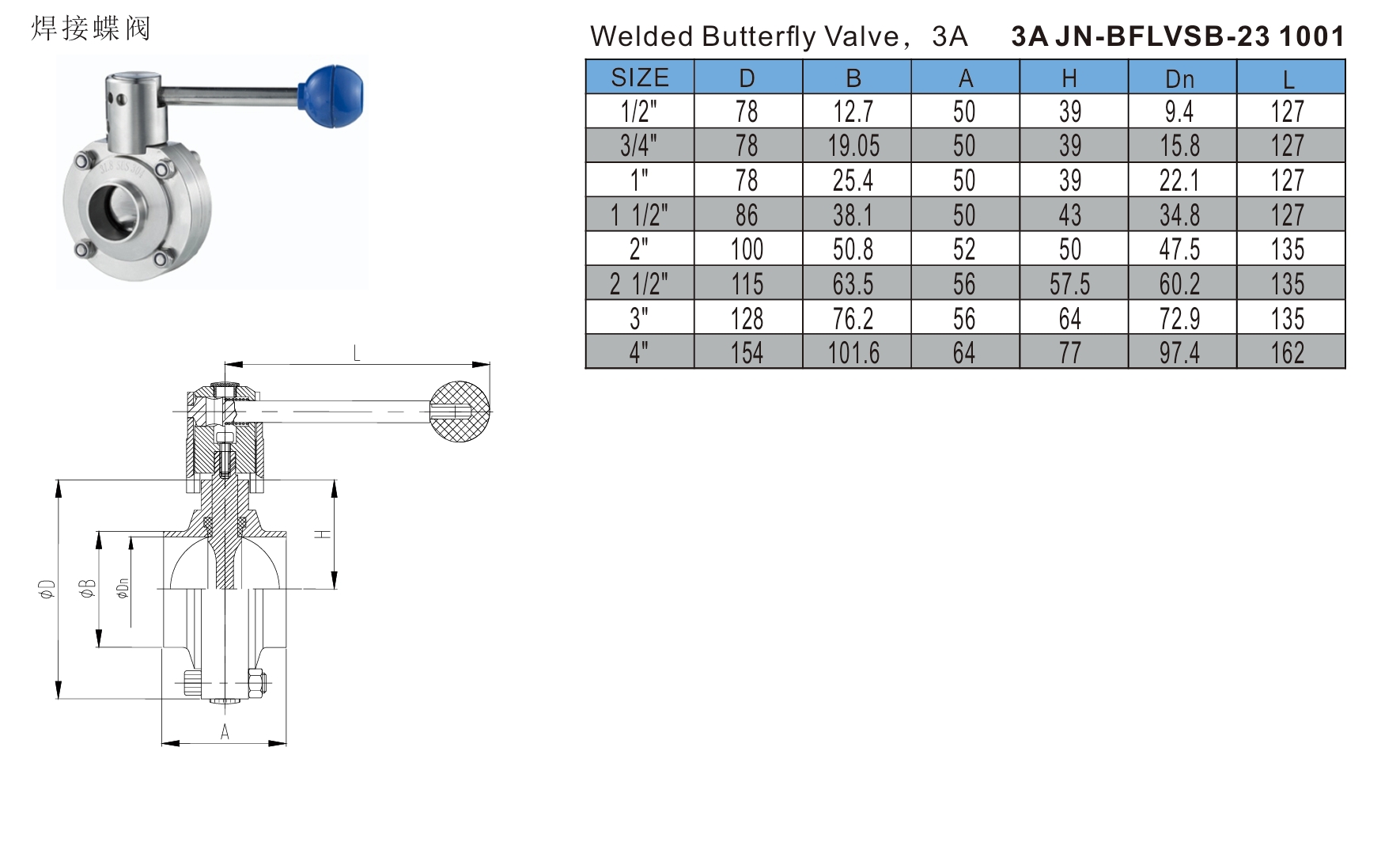

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● The stainless steel sanitary welded duckbill manual butterfly valve adopts a duckbill sealing structure to effectively prevent fluid leakage and ensure the sealing of the system.

● The stainless steel sanitary welded duckbill manual butterfly valve adopts welding connection, which reduces the leakage problem that may occur at the threaded connection.

● The stainless steel sanitary welded duckbill manual butterfly valve body, valve disc and sealing components are all made of 304 or 316L stainless steel, which has strong corrosion resistance.

● The stainless steel sanitary welded duckbill manual butterfly valve adopts a manual butterfly valve design, which is easy to operate and suitable for simple adjustment and control of fluid flow.

● The flow channel in the body of the stainless steel sanitary welded duckbill manual butterfly valve is streamlined, which reduces fluid resistance and improves flow efficiency.

● The stainless steel sanitary welded duckbill manual butterfly valve has a compact design and occupies a small space, which is suitable for installation in narrow or limited spaces.

Application

The industries where stainless steel sanitary welded duckbill manual butterfly valves are applied are mainly the following: Food industry: used to control the flow and flow of liquids during food processing. Beverage industry: control the flow of fluids in beverage production lines to ensure hygiene requirements. Pharmaceutical industry: regulate the flow of fluids in drug production to ensure clean standards. Dairy industry: ensure the control and sealing of fluids in dairy production. Chemical industry: used for switch control of chemical fluids to prevent leakage and contamination. Water treatment industry: Accurately adjust the flow rate during water treatment to ensure treatment effect.

Working Principles

The working principle of the stainless steel sanitary welded duckbill manual butterfly valve is to control the flow of fluid based on the rotation of the valve disc. When the valve stem is manually operated, the valve disc rotates around its axis. Its key feature is the "duckbill seal design". A duckbill seal structure is used between the edge of the valve disc and the pipe. When the valve is fully closed, the valve disc and the valve body are tightly sealed to ensure that the fluid does not leak. Using a stainless steel sanitary welded duckbill manual butterfly valve can ensure a stable flow of fluid and avoid system failures caused by flow fluctuations.

The options of the stainless steel sanitary welded duckbill manual butterfly valve include:

Valve body material: 304 stainless steel, 316L stainless steel.

Sealing material: EPDM, PTFE, silicone.

Connection method: welding connection.

Valve disc type: flat valve disc, duckbill valve disc.

Operation method: manual operation, with locking device.

Size selection: customized according to the pipe diameter.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Features

● The stainless steel sanitary welded duckbill manual butterfly valve adopts a duckbill sealing structure to effectively prevent fluid leakage and ensure the sealing of the system.

● The stainless steel sanitary welded duckbill manual butterfly valve adopts welding connection, which reduces the leakage problem that may occur at the threaded connection.

● The stainless steel sanitary welded duckbill manual butterfly valve body, valve disc and sealing components are all made of 304 or 316L stainless steel, which has strong corrosion resistance.

● The stainless steel sanitary welded duckbill manual butterfly valve adopts a manual butterfly valve design, which is easy to operate and suitable for simple adjustment and control of fluid flow.

● The flow channel in the body of the stainless steel sanitary welded duckbill manual butterfly valve is streamlined, which reduces fluid resistance and improves flow efficiency.

● The stainless steel sanitary welded duckbill manual butterfly valve has a compact design and occupies a small space, which is suitable for installation in narrow or limited spaces.

Application

The industries where stainless steel sanitary welded duckbill manual butterfly valves are applied are mainly the following: Food industry: used to control the flow and flow of liquids during food processing. Beverage industry: control the flow of fluids in beverage production lines to ensure hygiene requirements. Pharmaceutical industry: regulate the flow of fluids in drug production to ensure clean standards. Dairy industry: ensure the control and sealing of fluids in dairy production. Chemical industry: used for switch control of chemical fluids to prevent leakage and contamination. Water treatment industry: Accurately adjust the flow rate during water treatment to ensure treatment effect.