| Availability: | |

|---|---|

| Quantity: | |

JN 1005

JONENG

8481804090

Stainless Steel Sanitary EPDM Welded Stop Diverter Valve

The stainless steel sanitary diverter valve is designed to achieve accurate distribution of fluids in the pipeline system. It can effectively divert fluids from the main pipe to multiple branch pipes to meet the needs of different process links. The valve is made of stainless steel, which can ensure stability under frequent cleaning and high-pressure environments and avoid fluid contamination. By controlling the flow rate, flow rate and distribution position, the stainless steel sanitary diverter valve helps to optimize the production process, improve production efficiency and ensure product quality. In these high-standard production environments, diverter valves play a vital role in ensuring efficient, leak-free and stable operation of the entire system.

Working Principles

The working principle of stainless steel sanitary diverter valves is based on the control and distribution of fluids. First, the fluid enters through the inlet of the valve, and the regulating mechanism inside the valve (such as ball, butterfly plate, etc.) adjusts the flow path of the fluid according to the set opening or signal. By adjusting the valve opening, the fluid is distributed to multiple outlet pipes. Manual diverter valves control the flow through manual operation, while electric or pneumatic diverter valves are automatically adjusted through electric or pneumatic drive devices. The design of the valve ensures that the fluid will not be contaminated during the distribution process, and is particularly suitable for industries that require high hygiene standards, such as food, pharmaceuticals, etc.

Common options for stainless steel sanitary diverter valves are as follows, listed briefly:

Connection method: quick installation, thread, welding

Drive mode: manual, electric, pneumatic

Valve body structure: three-way, four-way, L-type, T-type

Sealing material: EPDM, PTFE, silicone

Surface treatment: internal and external polishing, pickling and passivation

Control accessories: positioner, limit switch, feedback device

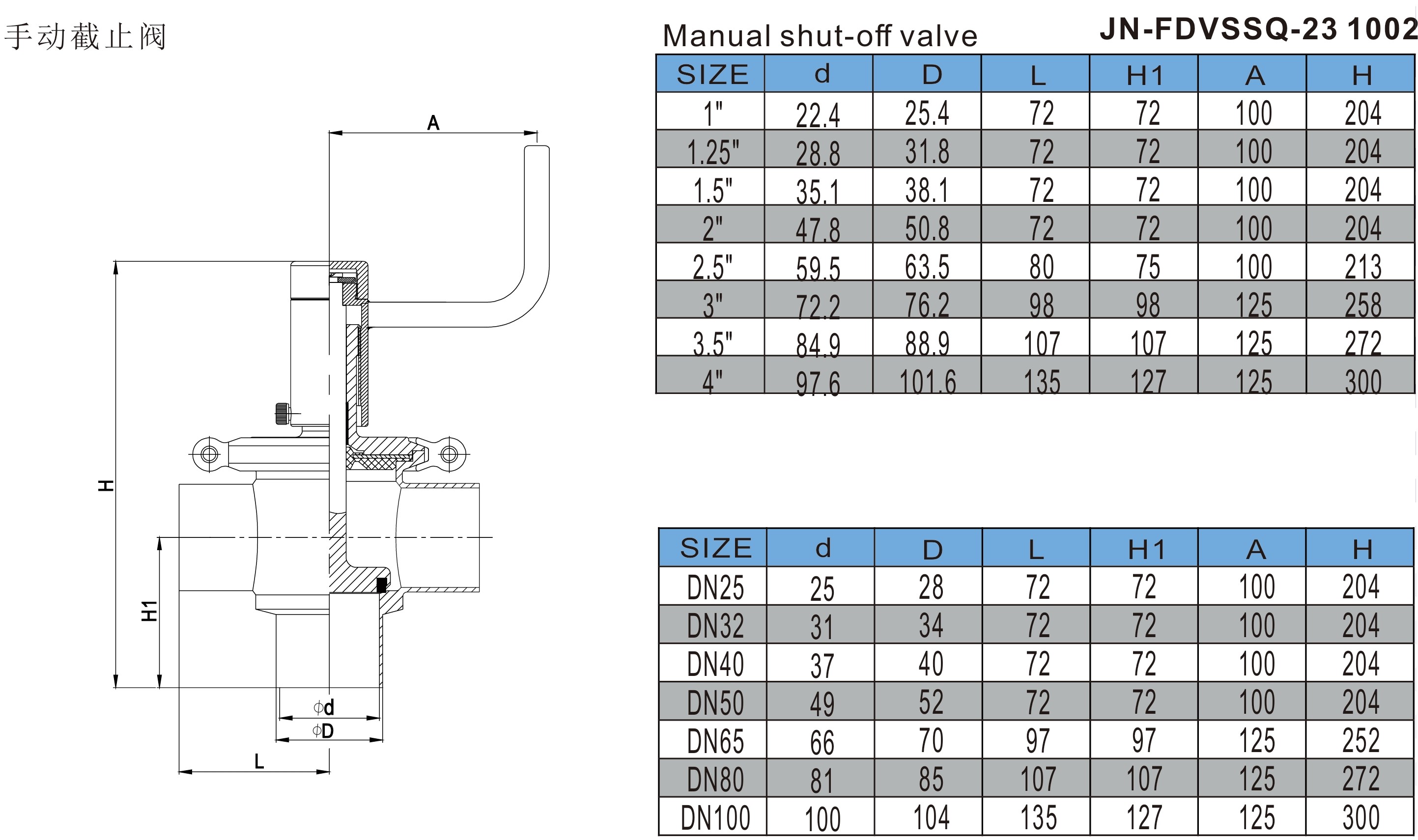

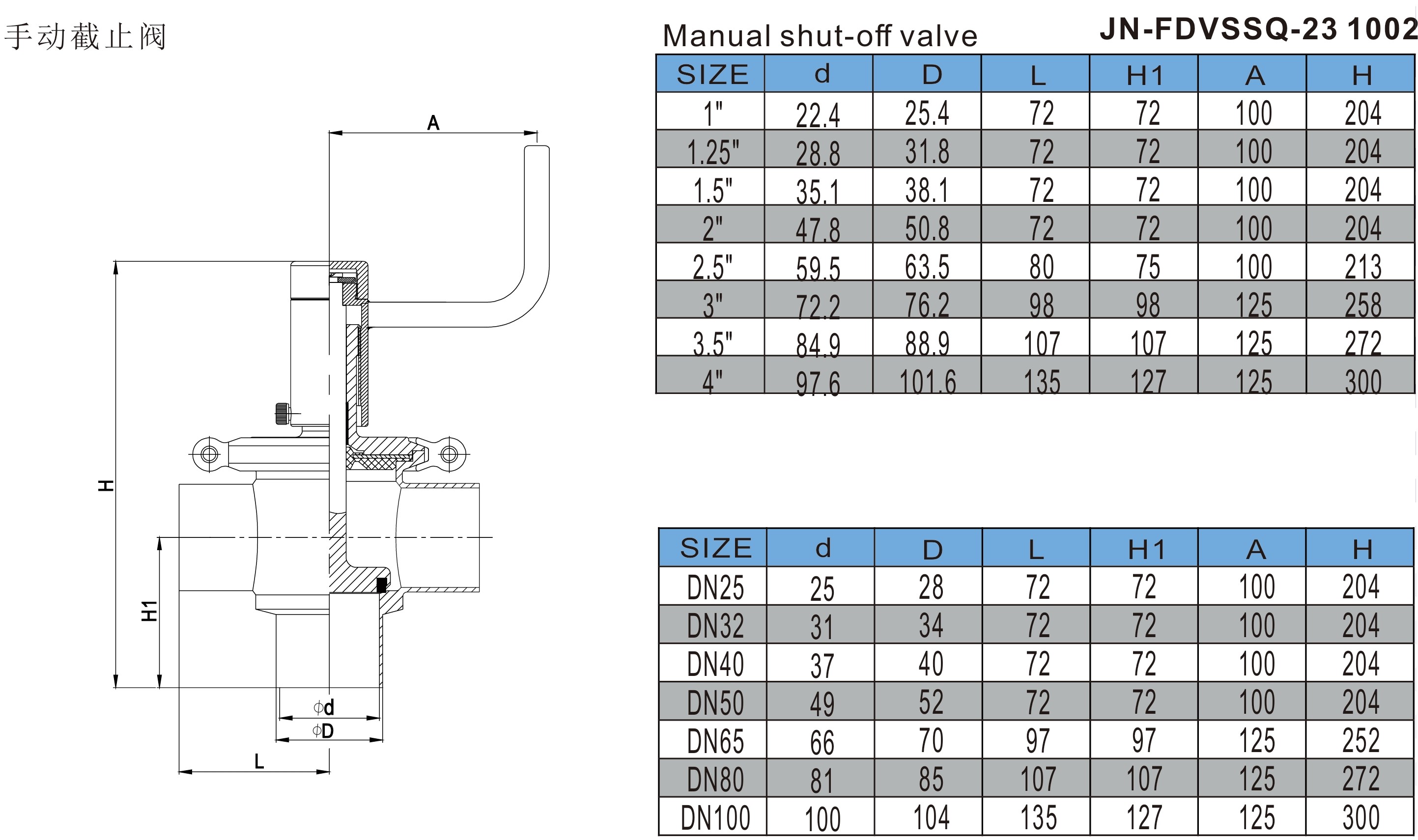

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The inner cavity of the stainless steel sanitary diverter valve body adopts an asymmetric flow guide structure optimized by computational fluid dynamics (CFD), which forms controllable turbulence during diversion and makes the medium mixing more uniform.

● The stainless steel sanitary diverter valve uses a nickel-titanium alloy memory metal spring as the valve disc drive element, which automatically adjusts the sealing pressure when the temperature changes, and can still maintain a constant clamping force after high-temperature sterilization, solving the problem of thermal aging of traditional elastomer seals.

● The stainless steel sanitary diverter valve injects nano-scale magnetic fluid into the valve stem to form a liquid sealing barrier under the action of an external magnetic field, completely eliminating the dynamic leakage of rotating parts.

● The surface of the stainless steel sanitary diverter valve seat is inlaid with a micron-level pyramid-shaped ceramic array, which produces a micro-shearing effect when the valve is opened and closed to prevent the crystallization and deposition of protein or sugar media on the sealing surface.

● The stainless steel sanitary diverter valve body integrates a PZT piezoelectric sensor array to monitor the flow fluctuations of each branch in real time and display it through the HMI, far exceeding the ±5% accuracy of traditional mechanical flow meters.

● The surface of the stainless steel sanitary diverter valve flow channel is treated with plasma enhanced chemical vapor deposition to form a nanostructured super-hydrophobic layer similar to the lotus leaf effect, with a contact angle of >150°.

Application

Stainless steel sanitary diverter valves are widely used in the following industries, each of which has high requirements for its hygiene, safety and corrosion resistance: Food processing industry: used to control the flow direction and distribution of beverages, dairy products, sauces, etc. Dairy industry: used for clean delivery and pipeline switching of milk, yogurt, etc. Biopharmaceutical industry: used for fluid diversion in high-cleanliness systems such as liquid medicine and injection. Daily chemical products industry: suitable for distribution pipelines for products such as shampoo, shower gel, and skin care products. Beer and beverage industry: switch fluid direction in filling and conveying lines of alcohol, carbonated beverages, juices, etc.

Working Principles

The working principle of stainless steel sanitary diverter valves is based on the control and distribution of fluids. First, the fluid enters through the inlet of the valve, and the regulating mechanism inside the valve (such as ball, butterfly plate, etc.) adjusts the flow path of the fluid according to the set opening or signal. By adjusting the valve opening, the fluid is distributed to multiple outlet pipes. Manual diverter valves control the flow through manual operation, while electric or pneumatic diverter valves are automatically adjusted through electric or pneumatic drive devices. The design of the valve ensures that the fluid will not be contaminated during the distribution process, and is particularly suitable for industries that require high hygiene standards, such as food, pharmaceuticals, etc.

Common options for stainless steel sanitary diverter valves are as follows, listed briefly:

Connection method: quick installation, thread, welding

Drive mode: manual, electric, pneumatic

Valve body structure: three-way, four-way, L-type, T-type

Sealing material: EPDM, PTFE, silicone

Surface treatment: internal and external polishing, pickling and passivation

Control accessories: positioner, limit switch, feedback device

Feature and Specification

Stainless Steel Flow Diversion Valve Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The inner cavity of the stainless steel sanitary diverter valve body adopts an asymmetric flow guide structure optimized by computational fluid dynamics (CFD), which forms controllable turbulence during diversion and makes the medium mixing more uniform.

● The stainless steel sanitary diverter valve uses a nickel-titanium alloy memory metal spring as the valve disc drive element, which automatically adjusts the sealing pressure when the temperature changes, and can still maintain a constant clamping force after high-temperature sterilization, solving the problem of thermal aging of traditional elastomer seals.

● The stainless steel sanitary diverter valve injects nano-scale magnetic fluid into the valve stem to form a liquid sealing barrier under the action of an external magnetic field, completely eliminating the dynamic leakage of rotating parts.

● The surface of the stainless steel sanitary diverter valve seat is inlaid with a micron-level pyramid-shaped ceramic array, which produces a micro-shearing effect when the valve is opened and closed to prevent the crystallization and deposition of protein or sugar media on the sealing surface.

● The stainless steel sanitary diverter valve body integrates a PZT piezoelectric sensor array to monitor the flow fluctuations of each branch in real time and display it through the HMI, far exceeding the ±5% accuracy of traditional mechanical flow meters.

● The surface of the stainless steel sanitary diverter valve flow channel is treated with plasma enhanced chemical vapor deposition to form a nanostructured super-hydrophobic layer similar to the lotus leaf effect, with a contact angle of >150°.

Application

Stainless steel sanitary diverter valves are widely used in the following industries, each of which has high requirements for its hygiene, safety and corrosion resistance: Food processing industry: used to control the flow direction and distribution of beverages, dairy products, sauces, etc. Dairy industry: used for clean delivery and pipeline switching of milk, yogurt, etc. Biopharmaceutical industry: used for fluid diversion in high-cleanliness systems such as liquid medicine and injection. Daily chemical products industry: suitable for distribution pipelines for products such as shampoo, shower gel, and skin care products. Beer and beverage industry: switch fluid direction in filling and conveying lines of alcohol, carbonated beverages, juices, etc.