| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Sanitary Four-way Spherical Sight Glass for Pipeline

The core of the design of the stainless steel sanitary four-way spherical sight glass is to achieve all-round transparent observation at the sanitary pipeline nodes where multiple flow directions intersect, while taking into account flow direction switching and real-time status monitoring. It is not only a monitoring window, but also a combination of fluid visualization and pipeline layout flexibility. It meets the dynamic judgment of medium color, impurities, and bubbles in the production process, as well as the residual detection needs during the cleaning process, and improves the intuitiveness and timeliness of process safety and quality control.

Working Principles

The working principle of the stainless steel sanitary four-way spherical sight glass is to collect or divert multiple processes or media through a four-way pipeline structure. When the fluid passes through the four-way node, the transparent spherical observation window provides 360° all-round real-time visual monitoring for operators or automatic detection systems. The transparent sphere is usually made of high-strength tempered glass or other pressure-resistant transparent materials, which can withstand a certain pipeline pressure while ensuring that the flow state of media such as liquids, gases or slurries is clearly visible. Through the sight glass, the operator can directly observe the color, transparency, and whether it contains bubbles or impurities.

The options of the stainless steel sanitary four-way spherical sight glass include:

Connection method: quick installation, welding, flange.

Sight glass material: tempered glass, high temperature and high pressure resistant glass.

Surface treatment: mirror polishing, electrolytic polishing.

Built-in lighting: LED light or explosion-proof lamp.

Pressure level: normal pressure type, high pressure type.

Special functions: explosion-proof, anti-fogging, and cleaning nozzles can be added.

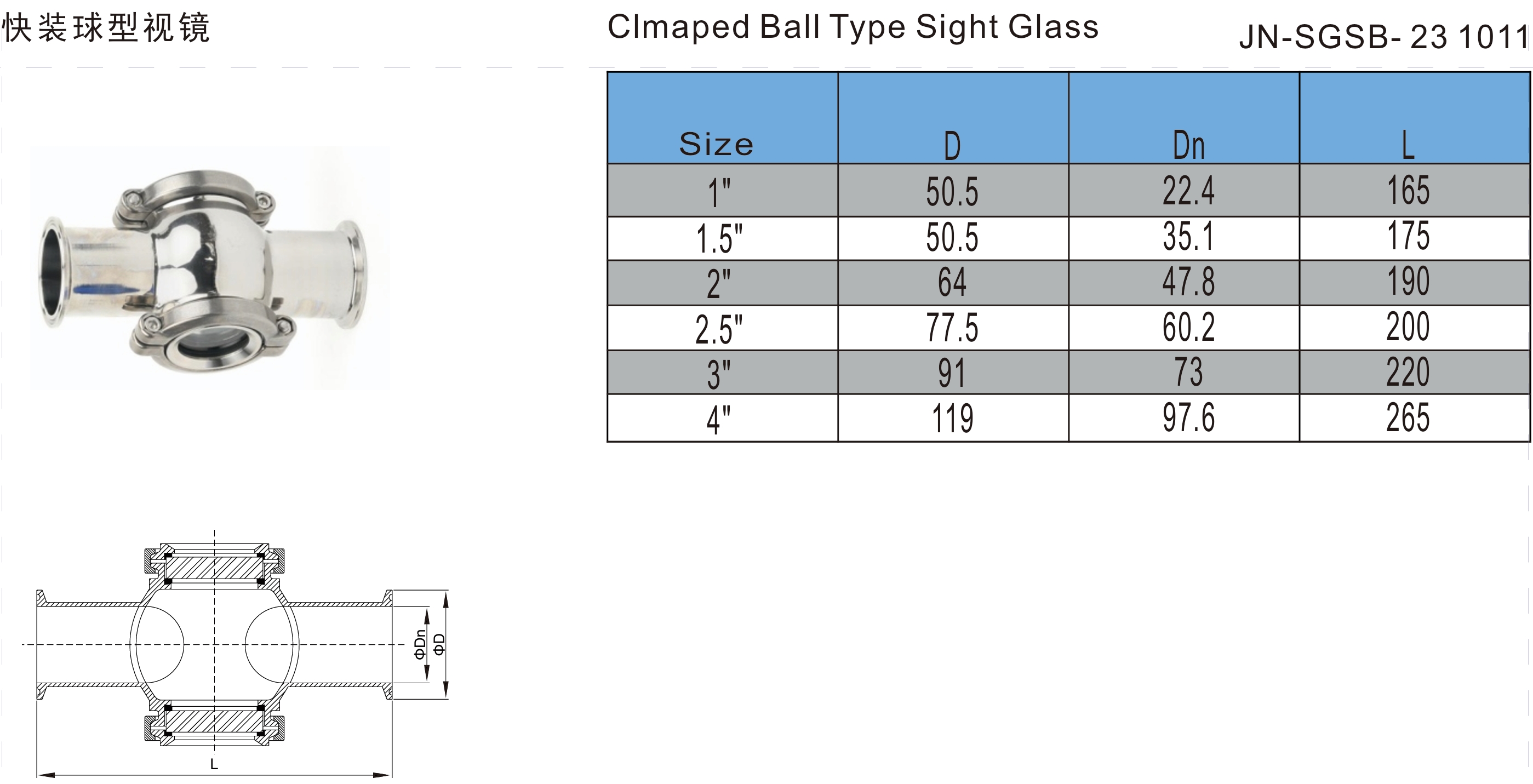

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The transition section inside the stainless steel sanitary four-way spherical sight glass adopts an arc-shaped flow-guiding transition to ensure that no obvious dead corners or vortices are formed when the fluid converges or diverges from four directions.

● The stainless steel sanitary four-way spherical sight glass adopts a 360° equidistant fine polishing process inside and outside, and the finish is below Ra0.2μm.

● The stainless steel sanitary four-way spherical sight glass adopts a floating seal design between the sphere and the stainless steel body. When the pipeline expands and contracts or the pressure fluctuates instantly, the sealing ring can deform slightly adaptively.

● The stainless steel sanitary four-way spherical sight glass has multiple micro-temperature sensor installation channels reserved between the cavity of the sight glass sphere and the four-way wall thickness, which can simultaneously monitor the temperature difference of fluids in different flow directions.

● The stainless steel sanitary four-way spherical sight glass is equipped with a micro-sampling or negative pressure sampling port on the top or side wall of the spherical sight glass, and trace liquid samples inside the pipeline can be extracted without disassembly.

● The stainless steel sanitary four-way spherical sight glass is designed with a micro-guide groove at the junction of the sight glass and the body, which automatically collects and discharges the condensate by using the surface tension difference of the condensate.

Application

Stainless steel sanitary four-way spherical sight glasses are widely used in the following industries: Food and beverage industry: visual monitoring of raw materials and finished liquids to ensure quality. Pharmaceutical and biological industry: real-time observation and online detection of water pipelines. Cosmetics and personal care industry: monitoring material mixing uniformity and impurities. Fine chemical industry: monitoring liquid color changes and transparency during production. Electronic semiconductor industry: ensuring liquid pollution-free, suitable for high standards of clean workshops. New energy industry: monitoring the status of key material delivery and mixing processes. Environmental water treatment industry: visual monitoring of high-purity water, reverse osmosis water, and ultrafiltration liquids.

Working Principles

The working principle of the stainless steel sanitary four-way spherical sight glass is to collect or divert multiple processes or media through a four-way pipeline structure. When the fluid passes through the four-way node, the transparent spherical observation window provides 360° all-round real-time visual monitoring for operators or automatic detection systems. The transparent sphere is usually made of high-strength tempered glass or other pressure-resistant transparent materials, which can withstand a certain pipeline pressure while ensuring that the flow state of media such as liquids, gases or slurries is clearly visible. Through the sight glass, the operator can directly observe the color, transparency, and whether it contains bubbles or impurities.

The options of the stainless steel sanitary four-way spherical sight glass include:

Connection method: quick installation, welding, flange.

Sight glass material: tempered glass, high temperature and high pressure resistant glass.

Surface treatment: mirror polishing, electrolytic polishing.

Built-in lighting: LED light or explosion-proof lamp.

Pressure level: normal pressure type, high pressure type.

Special functions: explosion-proof, anti-fogging, and cleaning nozzles can be added.

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The transition section inside the stainless steel sanitary four-way spherical sight glass adopts an arc-shaped flow-guiding transition to ensure that no obvious dead corners or vortices are formed when the fluid converges or diverges from four directions.

● The stainless steel sanitary four-way spherical sight glass adopts a 360° equidistant fine polishing process inside and outside, and the finish is below Ra0.2μm.

● The stainless steel sanitary four-way spherical sight glass adopts a floating seal design between the sphere and the stainless steel body. When the pipeline expands and contracts or the pressure fluctuates instantly, the sealing ring can deform slightly adaptively.

● The stainless steel sanitary four-way spherical sight glass has multiple micro-temperature sensor installation channels reserved between the cavity of the sight glass sphere and the four-way wall thickness, which can simultaneously monitor the temperature difference of fluids in different flow directions.

● The stainless steel sanitary four-way spherical sight glass is equipped with a micro-sampling or negative pressure sampling port on the top or side wall of the spherical sight glass, and trace liquid samples inside the pipeline can be extracted without disassembly.

● The stainless steel sanitary four-way spherical sight glass is designed with a micro-guide groove at the junction of the sight glass and the body, which automatically collects and discharges the condensate by using the surface tension difference of the condensate.

Application

Stainless steel sanitary four-way spherical sight glasses are widely used in the following industries: Food and beverage industry: visual monitoring of raw materials and finished liquids to ensure quality. Pharmaceutical and biological industry: real-time observation and online detection of water pipelines. Cosmetics and personal care industry: monitoring material mixing uniformity and impurities. Fine chemical industry: monitoring liquid color changes and transparency during production. Electronic semiconductor industry: ensuring liquid pollution-free, suitable for high standards of clean workshops. New energy industry: monitoring the status of key material delivery and mixing processes. Environmental water treatment industry: visual monitoring of high-purity water, reverse osmosis water, and ultrafiltration liquids.