| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary screw pump is a volumetric conveying device that uses an eccentric screw and a stator to form a sealed cavity and pushes the fluid through continuous rotation. It not only has the characteristics of smooth and pulsation-free conveying, but also can handle medium containing particles, viscous or shear-sensitive, while maintaining the integrity of the fluid and ensuring hygiene requirements. Stainless steel sanitary screw pumps are usually installed in the conveying pipeline system of industries such as food, pharmaceuticals, cosmetics and fine chemicals. They are generally located at the outlet of the raw material storage tank, and can also be installed at the end of the production line to ensure that high-viscosity products are smoothly conveyed to the packaging equipment. There are mainly the following types of stainless steel sanitary screw pumps: single screw pump, twin screw pump, three screw pump, external meshing screw pump, internal meshing screw pump.

JONENG

8481804090

Stainless Steel Sanitary HIGH Vacuum Positive Displacement Progressive Cavity Pump

The original intention of the design of stainless steel sanitary screw pumps is not just to convey fluids, but to provide a gentle and stable transmission method in the process of conveying materials with high viscosity, instability or susceptible to shear. When handling high-viscosity or particle-containing media, traditional pumps are prone to pulses, uneven flow or material damage, while screw pumps achieve pulsation-free, low-shear conveying through a continuous sealed cavity structure to avoid changes in medium characteristics. Its special stator-rotor combination ensures that the pump can still maintain efficient delivery at low speed, so that sensitive materials such as emulsions, plasma, fermentation broth, etc. can maintain their original activity during long-term delivery. In addition, the pump structure is easy to disassemble and clean, and can meet CIP/SIP requirements, ensuring that each delivery meets high cleanliness standards, reducing material loss, and improving product quality and safety.

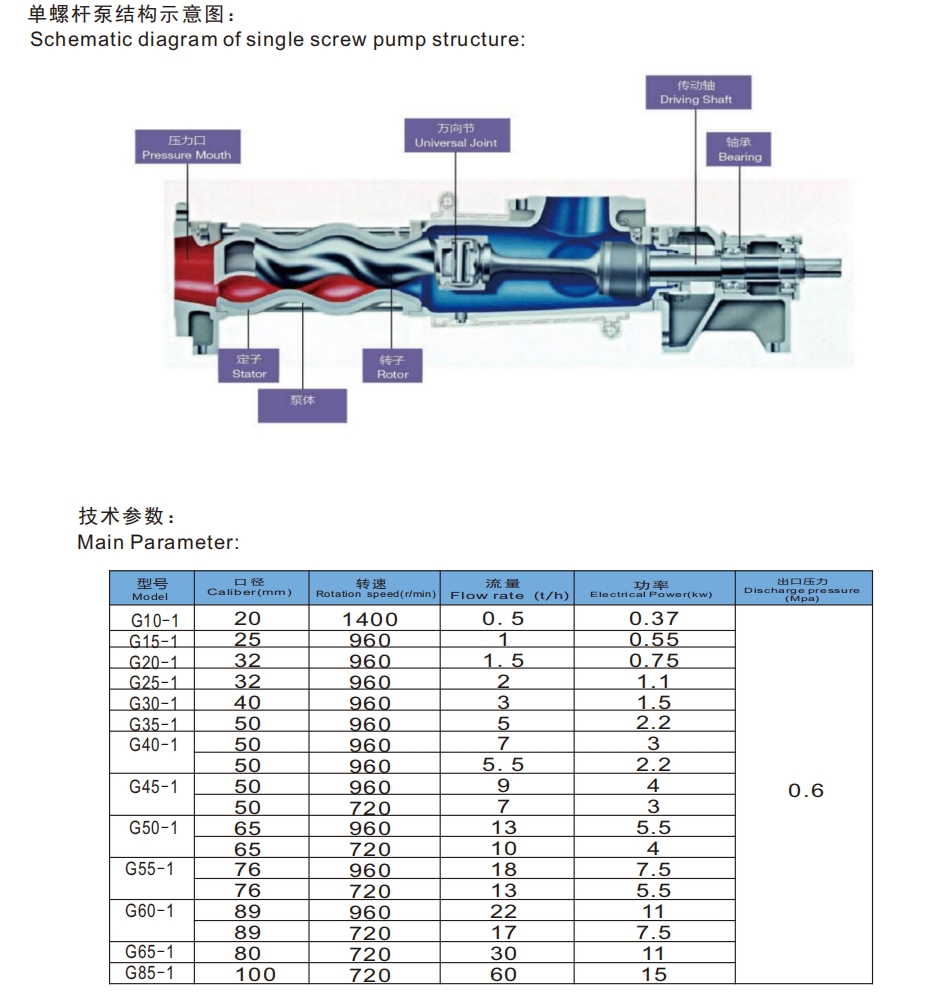

Working Principles

The working principle of the stainless steel sanitary screw pump is based on the principle of a positive displacement pump, and the fluid is transported through a sealed cavity between the rotor and the stator. First, when the pump is started, the spiral rotor begins to rotate, and with the cooperation of the stator, a series of closed cavities are formed. As the rotor rotates, the fluid is sucked into the pump cavity and gradually pushed along the spiral groove. The rotation of the rotor causes the fluid to move in the spiral groove, forming a steady flow pattern, avoiding the generation of pulsation and shear force. This process ensures that the fluid is smoothly delivered to the outlet of the pump, which is particularly suitable for materials with high viscosity or particles. In high-viscosity media, the low-speed operation of the pump reduces fluid damage, and can also effectively cope with the needs of high pressure and large flow. In this process, each spiral structure in the pump plays a role in reducing pressure fluctuations and improving conveying efficiency, ensuring the stability and integrity of the fluid during the conveying process.

Options for stainless steel sanitary screw pumps include:

Seal type: mechanical seal, lip seal, etc.

Drive mode: electric, pneumatic drive.

Flow control method: variable frequency speed regulation, manual adjustment.

Rotor material: different types of stainless steel (such as 304, 316L).

Installation method: horizontal installation or vertical installation.

Temperature adaptability: high temperature or low temperature adaptability options.

Protection level: optional protection level (such as IP65) to adapt to different environments.

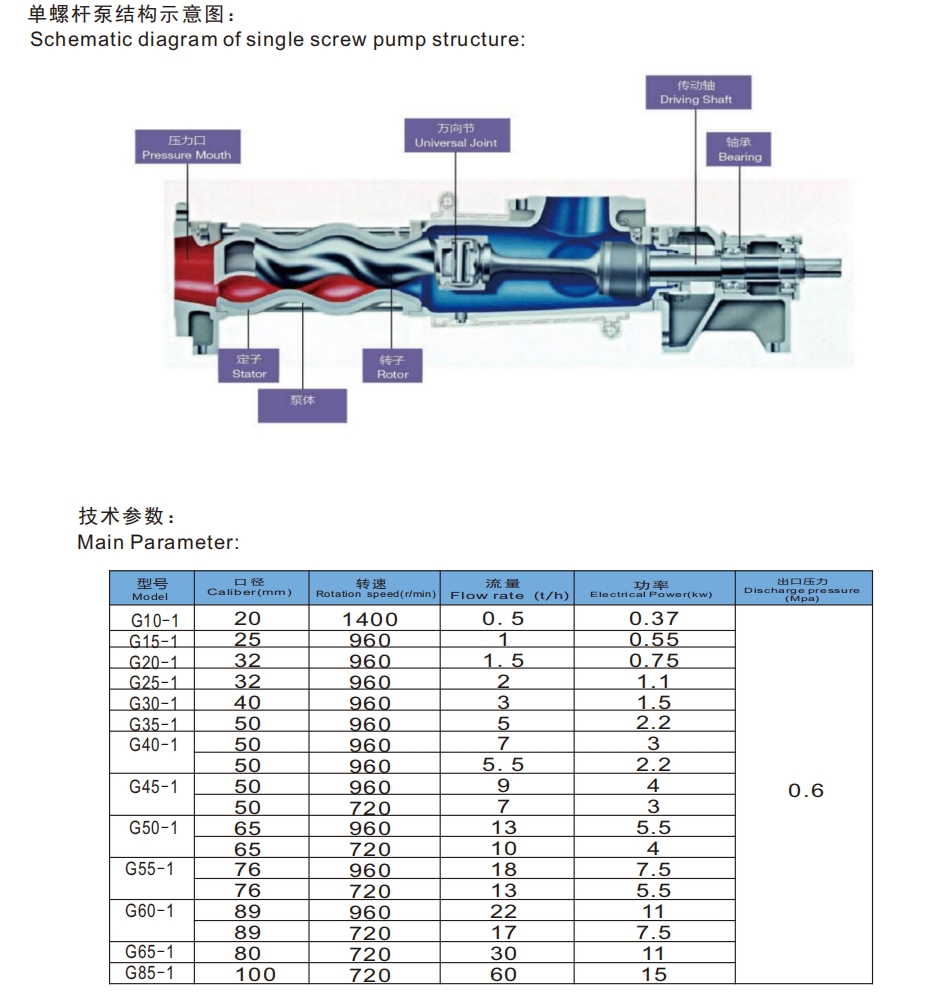

Specification Chart

Investment casting pump body | AISI 304/316L |

Gaskets | EPDM |

Mechanical sealing | C/SiC/EPDM |

Internal surface finish | Ra<=0.6mm |

External surface finish | mirror polished |

Max. speed | 720RPM |

Max. pressure | up to 12 bar |

Max. flow | 60m3/h |

Max. temp | up to 350oC |

Features

● The internal meshing design of the stainless steel sanitary screw pump ensures more uniform and stable fluid delivery, avoiding the instability caused by flow fluctuations in traditional single screw pumps.

● The stainless steel sanitary screw pump uses the volumetric working principle of the screw to reduce the shear force on the fluid, which is especially suitable for high shear sensitive media such as biological products.

● The stainless steel sanitary screw pump controls the pump speed through a frequency converter or manual adjustment, providing flexible flow regulation functions to adapt to different production needs.

● The stainless steel sanitary screw pump adopts a standardized design, and the components of the screw and stator can be interchanged according to different application requirements.

● The internal structure design of the stainless steel sanitary screw pump has a self-cleaning function to prevent high-viscosity materials from carbonizing or precipitating in the pump cavity.

● The corrosion-resistant coating is used inside the stainless steel sanitary screw pump body to further enhance the pump body's resistance to strong acids, strong alkalis and solvents.

Application

Stainless steel sanitary screw pumps are widely used in the following industries: Food industry: conveying juice, milk, sauces and other fluids with high hygiene requirements. Pharmaceutical industry: used for the transmission of sterile media such as liquid medicine and vaccines. Cosmetic industry: conveying high-viscosity products such as emulsions and essences. Chemical industry: handling corrosive chemicals and high-viscosity materials. Environmental protection industry: conveying sewage, sludge and other high-solid content media. Petroleum industry: used for transporting high-viscosity oil products such as crude oil and fuel oil. Papermaking industry: used for transporting high-viscosity raw materials such as pulp and glue. Construction industry: used for transporting viscous materials such as asphalt and paint.

Working Principles

The working principle of the stainless steel sanitary screw pump is based on the principle of a positive displacement pump, and the fluid is transported through a sealed cavity between the rotor and the stator. First, when the pump is started, the spiral rotor begins to rotate, and with the cooperation of the stator, a series of closed cavities are formed. As the rotor rotates, the fluid is sucked into the pump cavity and gradually pushed along the spiral groove. The rotation of the rotor causes the fluid to move in the spiral groove, forming a steady flow pattern, avoiding the generation of pulsation and shear force. This process ensures that the fluid is smoothly delivered to the outlet of the pump, which is particularly suitable for materials with high viscosity or particles. In high-viscosity media, the low-speed operation of the pump reduces fluid damage, and can also effectively cope with the needs of high pressure and large flow. In this process, each spiral structure in the pump plays a role in reducing pressure fluctuations and improving conveying efficiency, ensuring the stability and integrity of the fluid during the conveying process.

Options for stainless steel sanitary screw pumps include:

Seal type: mechanical seal, lip seal, etc.

Drive mode: electric, pneumatic drive.

Flow control method: variable frequency speed regulation, manual adjustment.

Rotor material: different types of stainless steel (such as 304, 316L).

Installation method: horizontal installation or vertical installation.

Temperature adaptability: high temperature or low temperature adaptability options.

Protection level: optional protection level (such as IP65) to adapt to different environments.

Specification Chart

Max. flow rate | 50m3/h |

Max viscosity | 100000Cps |

Power supply | 0.75kw to 22kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

| Motor type | variable frequency motor, fixed speed motor |

Max. flow rate | 50m3/h |

Frequency | 50HZ/60HZ |

Max. pressure | 8 bar |

Max. temperature | 110°C |

Material | SS304/SS316L |

| Inlet/outlet connection | Clamp, Weld, Flange |

| Inlet/outlet size | 1”-3” |

| Diaphragm | PTFE, PTFE with white back, EPDM, white EPDM, white NBR |

| Driving way | Air or Motor |

Features

● The internal meshing design of the stainless steel sanitary screw pump ensures more uniform and stable fluid delivery, avoiding the instability caused by flow fluctuations in traditional single screw pumps.

● The stainless steel sanitary screw pump uses the volumetric working principle of the screw to reduce the shear force on the fluid, which is especially suitable for high shear sensitive media such as biological products.

● The stainless steel sanitary screw pump controls the pump speed through a frequency converter or manual adjustment, providing flexible flow regulation functions to adapt to different production needs.

● The stainless steel sanitary screw pump adopts a standardized design, and the components of the screw and stator can be interchanged according to different application requirements.

● The internal structure design of the stainless steel sanitary screw pump has a self-cleaning function to prevent high-viscosity materials from carbonizing or precipitating in the pump cavity.

● The corrosion-resistant coating is used inside the stainless steel sanitary screw pump body to further enhance the pump body's resistance to strong acids, strong alkalis and solvents.

Application

Stainless steel sanitary screw pumps are widely used in the following industries: Food industry: conveying juice, milk, sauces and other fluids with high hygiene requirements. Pharmaceutical industry: used for the transmission of sterile media such as liquid medicine and vaccines. Cosmetic industry: conveying high-viscosity products such as emulsions and essences. Chemical industry: handling corrosive chemicals and high-viscosity materials. Environmental protection industry: conveying sewage, sludge and other high-solid content media. Petroleum industry: used for transporting high-viscosity oil products such as crude oil and fuel oil. Papermaking industry: used for transporting high-viscosity raw materials such as pulp and glue. Construction industry: used for transporting viscous materials such as asphalt and paint.