Stainless Steel Sanitary Mini Threaded exhaust Safety Relief Valve

Stainless Steel Sanitary Mini Threaded Exhaust Safety Relief Valve is a compact valve designed to release excess pressure safely in sanitary systems. Its threaded connection allows easy installation, while the stainless steel construction ensures durability, corrosion resistance, and hygienic operation in high-pressure applications

Working Principles

The working principle of a Stainless Steel Sanitary Mini Threaded Exhaust Safety Relief Valve is based on automatically releasing excess pressure to protect sanitary systems. When the system pressure exceeds the pre-set limit, the valve spring is compressed, lifting the valve disc from the seat and allowing fluid or gas to escape through the outlet. Once the pressure drops below the set value, the spring pushes the disc back onto the seat, sealing the system and preventing leakage. The threaded connection allows easy installation, while the stainless steel construction ensures corrosion resistance, durability, and hygienic operation in food, beverage, pharmaceutical, or other sanitary applications

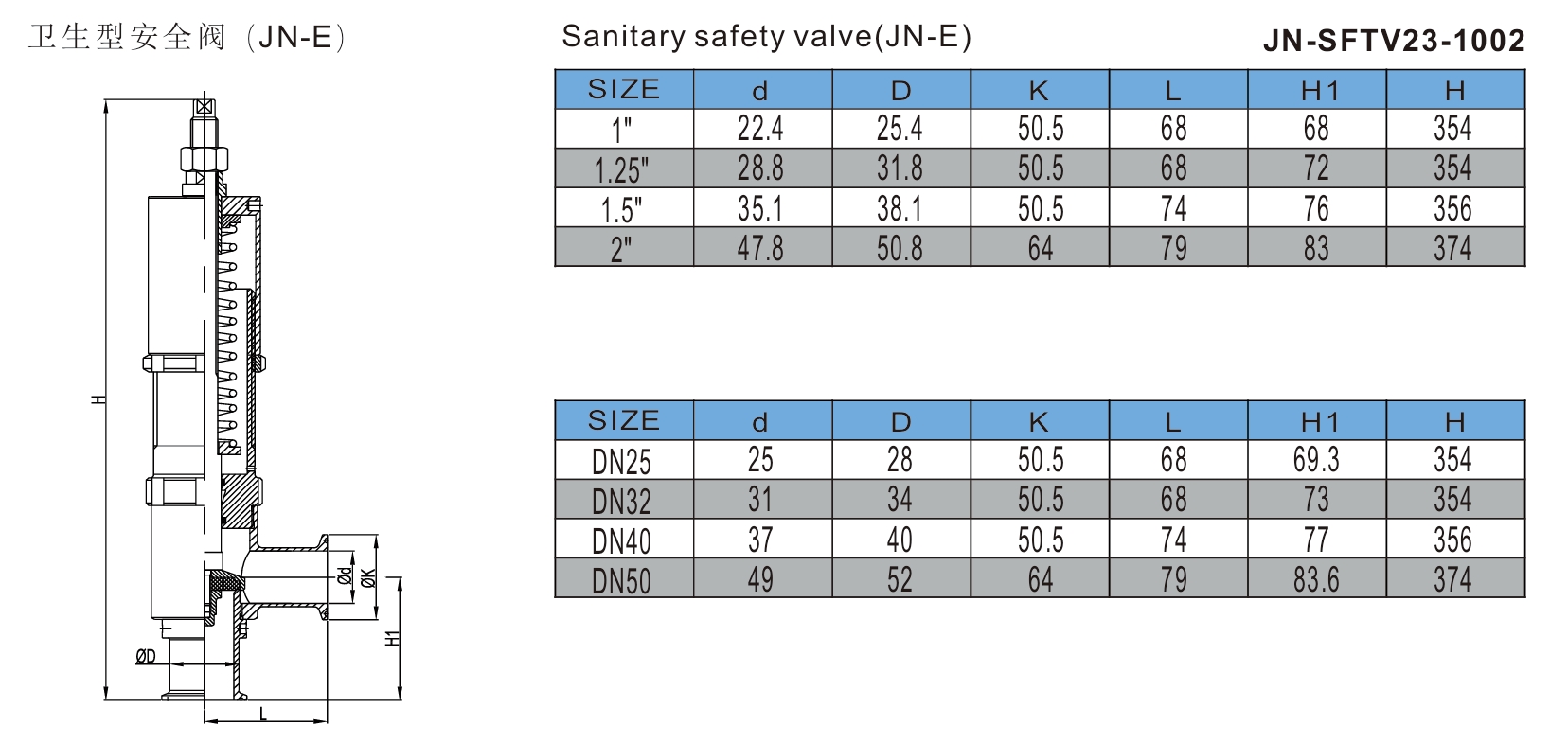

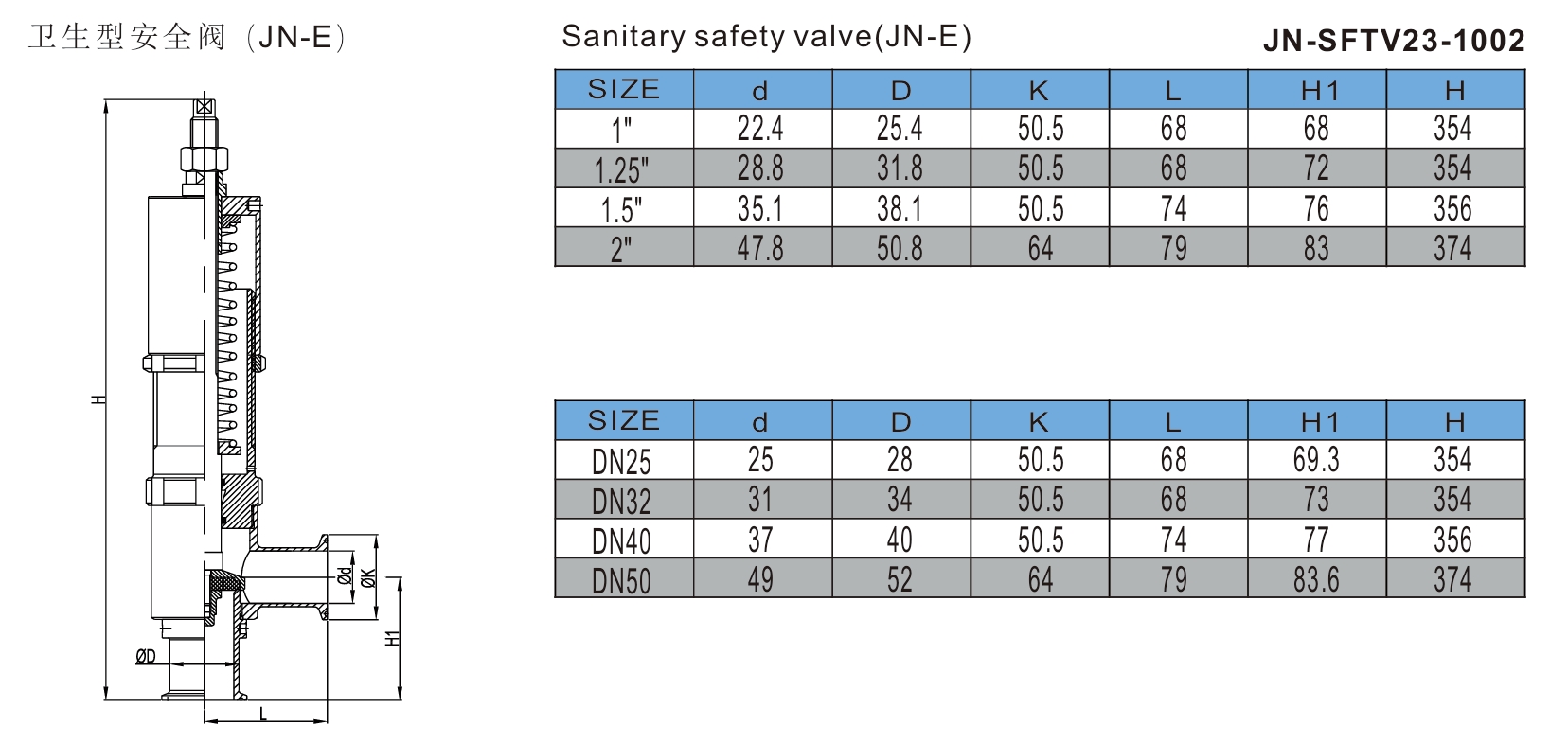

Stainless Steel Safety Valve Specification Chart

Type

|

Ball type, line type

|

Working Pressure |

0bar-10bar

|

Working Temperature

|

-10°C ~ +121°C

|

Connection end

|

welded,clamped , threaded, union type |

Connection Standards

|

DIN, SMS, 3A, ISO

|

Size |

1”-4”, DN25-DN100

|

Material

|

SS304, SS316L from solid bar raw material

|

| With internal finishing Ra16<0.4micron |

Surface finish | Sand blasting type, or mirror type |

Seal Material | FDA approved EPDM, VITION, NBR, SILICOME |

| Adjusting pressure | 0.5bar/unit |

| Manually adjustable to keep the system safety |

Lock can be available for settling the relief pressure |

Features

Constructed from high-quality stainless steel, providing excellent corrosion resistance and long-lasting durability in sanitary systems.

Miniature threaded design allows compact installation and easy integration into small pipelines or equipment.

Safety relief function automatically releases excess pressure to protect equipment and maintain safe operation.

Hygienic polished surfaces minimize contamination risk and support clean-in-place (CIP) procedures.

Spring-loaded mechanism ensures reliable, repeatable performance with fast response to overpressure conditions.

Application

Stainless Steel Sanitary Mini Threaded Exhaust Safety Relief Valves are widely used in pharmaceutical and biotechnology industries to protect small-scale reactors, fermenters, or pipelines from overpressure. They are also applied in food and beverage production, such as dairy or juice processing, where maintaining safe operating pressure is critical. Their compact size, threaded connection, and hygienic stainless steel construction make them ideal for systems requiring precise pressure control, easy installation, and compliance with sanitary standards.