| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Sanitary Pipe Straight-through Quick-install Sight Glass

The stainless steel sanitary pipeline straight-through quick-install sight glass is designed to monitor and observe the quality and state of the fluid in the pipeline in real time, especially in an environment with high hygiene requirements. Through the transparent sight glass window, the operator can clearly observe the flow, color and possible abnormalities of the fluid in the pipeline to ensure that the production process meets strict hygiene standards. This sight glass adopts a quick-install design and can be quickly installed and disassembled, reducing the cumbersome steps in the traditional installation process and improving the work efficiency of the production line. In addition, the sight glass can be used to check whether there are impurities, bubbles or sediments in the pipeline, detect problems in advance and deal with them in time, so as to avoid risks such as pipeline blockage and pollution.

Working Principles

The working principle of the stainless steel sanitary pipeline straight-through quick-install sight glass is based on the visual observation of the fluid through the transparent sight glass window. First, the fluid enters the pipeline and flows through the straight-through part of the pipeline. When the fluid passes through the sight glass device, the sight glass window provides a transparent field of view, allowing the operator to clearly see the state, color, flow rate and whether there are impurities in the fluid in the pipeline. The observation window in the sight glass is usually made of corrosion-resistant and high-temperature resistant stainless steel and tempered glass to ensure that long-term use will not affect vision. In order to improve the observation effect, some sight glasses may be equipped with built-in lighting devices to ensure clear visibility even in low-light environments.

The options for the stainless steel sanitary pipe straight-through quick-install sight glass include:

Sight glass material: stainless steel 304/316L

Window material: tempered glass, polycarbonate

Sight glass size: customized according to the pipe diameter (such as DN25-DN150)

Lighting system: built-in LED lighting, no lighting

Connection method: clamp type, thread type

Cleaning function: manual cleaning, automatic cleaning

Pressure level: design to adapt to different pressures

Seal material: silicone, EPDM, Viton

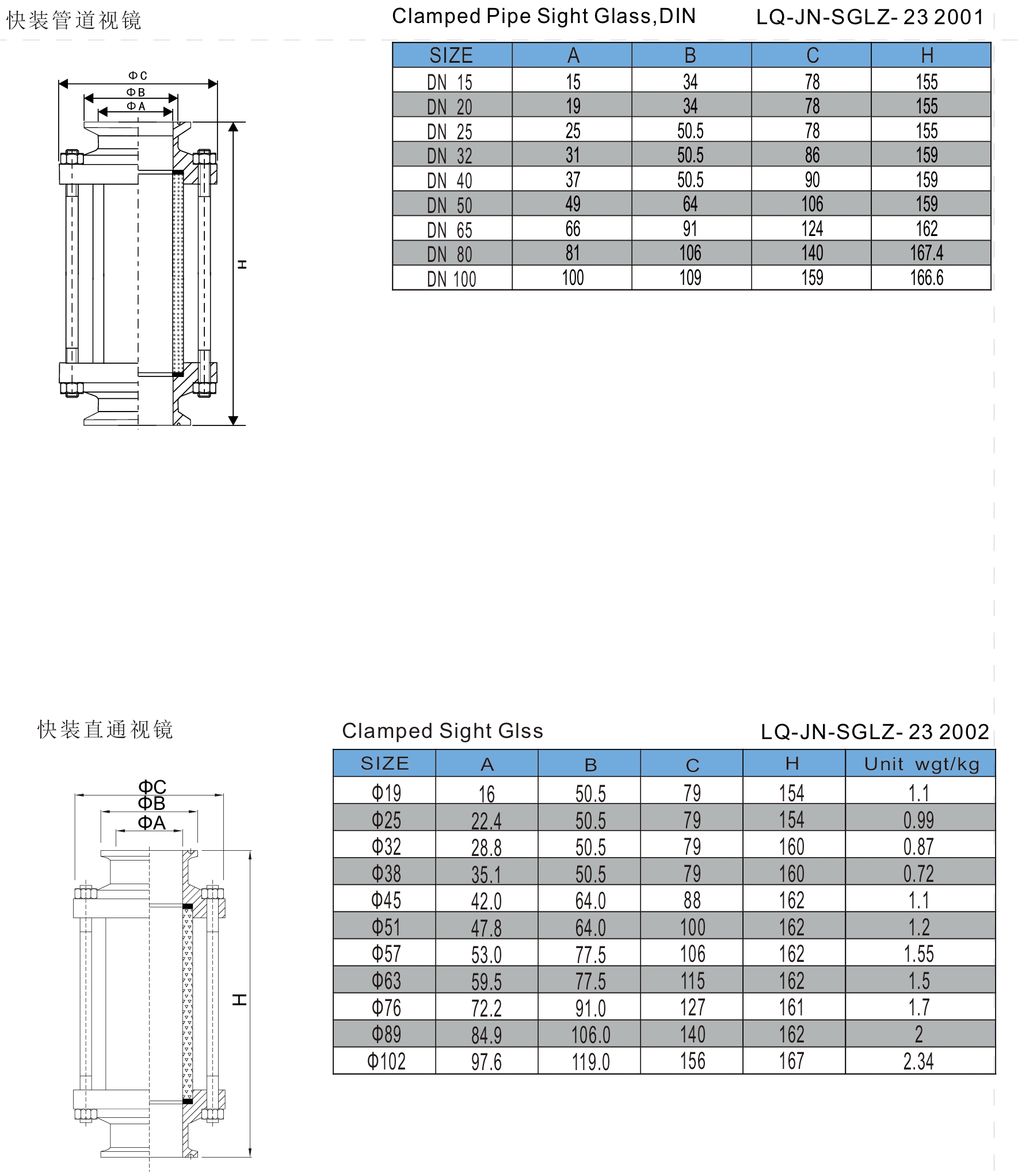

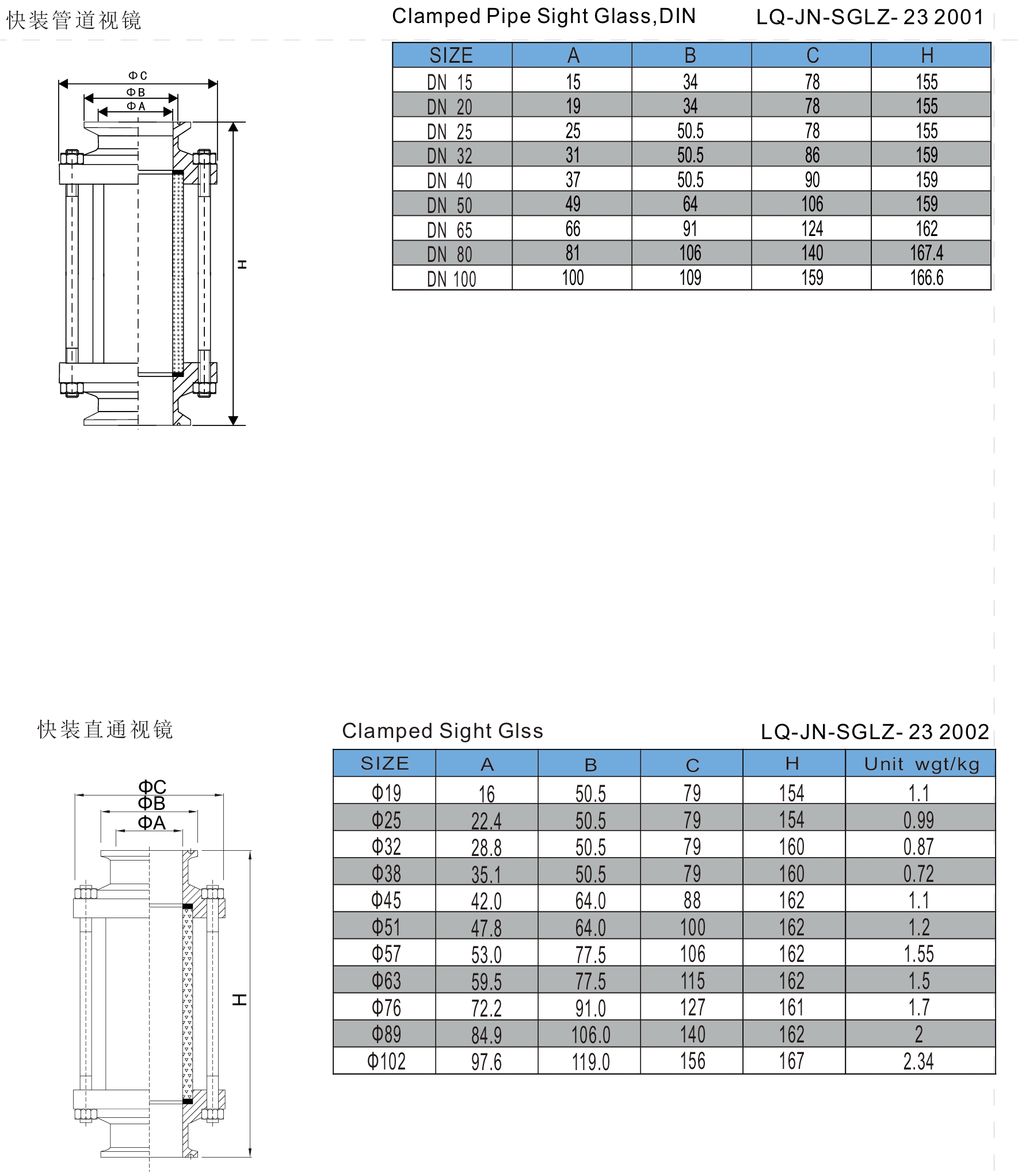

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary pipeline direct quick-install sight glass adopts plasma-assisted magnetron sputtering coating technology to deposit a nano-scale zirconium oxide-diamond-like carbon composite film layer on the surface of the lens.

● The stainless steel sanitary pipeline direct quick-install sight glass is designed with a micro-spiral guide channel in the sealing ring groove, which will produce a local eddy current effect when the medium flows through.

● The stainless steel sanitary pipeline direct quick-install sight glass adopts a multi-layer composite sapphire-alumina ceramic material manufactured by a gradient sintering process, with a high-toughness matrix as the inner layer and an ultra-hard wear-resistant layer as the outer layer.

● The stainless steel sanitary pipeline direct quick-install sight glass integrates a micro-piezoelectric ceramic vibrator inside the sight glass body, and the lens produces nano-level amplitude vibration through ultrasonic vibration of a specific frequency.

● The stainless steel sanitary pipeline direct quick-install sight glass adopts an intelligent sealing ring made of shape memory alloy (SMA), which can automatically adjust the compression amount when the temperature changes.

● The stainless steel sanitary pipeline direct quick-install sight glass has a dual-channel argon protection system, which forms an inert gas barrier in the sight glass cavity, preventing both oxidation of the medium and fogging of the lens.

Application

Stainless steel sanitary pipeline straight-through quick-install sight glasses are widely used in the following industries: Food processing: monitor the state of food fluids to ensure that the production process is pollution-free. Beverage production: observe the flow of juice, dairy products, carbonated beverages, etc. Dairy industry: check the flow quality of dairy products such as milk and yogurt. Pharmaceutical industry: monitor the pipeline transportation process of liquid medicine, injection liquid, etc. Cosmetic manufacturing: observe the transportation status of pastes, emulsions and other materials. Fine chemicals: monitor the flow of high-purity chemical solutions. Biological fermentation: observe the flow of fermentation liquid and control the culture environment of bacteria.

Working Principles

The working principle of the stainless steel sanitary pipeline straight-through quick-install sight glass is based on the visual observation of the fluid through the transparent sight glass window. First, the fluid enters the pipeline and flows through the straight-through part of the pipeline. When the fluid passes through the sight glass device, the sight glass window provides a transparent field of view, allowing the operator to clearly see the state, color, flow rate and whether there are impurities in the fluid in the pipeline. The observation window in the sight glass is usually made of corrosion-resistant and high-temperature resistant stainless steel and tempered glass to ensure that long-term use will not affect vision. In order to improve the observation effect, some sight glasses may be equipped with built-in lighting devices to ensure clear visibility even in low-light environments.

The options for the stainless steel sanitary pipe straight-through quick-install sight glass include:

Sight glass material: stainless steel 304/316L

Window material: tempered glass, polycarbonate

Sight glass size: customized according to the pipe diameter (such as DN25-DN150)

Lighting system: built-in LED lighting, no lighting

Connection method: clamp type, thread type

Cleaning function: manual cleaning, automatic cleaning

Pressure level: design to adapt to different pressures

Seal material: silicone, EPDM, Viton

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary pipeline direct quick-install sight glass adopts plasma-assisted magnetron sputtering coating technology to deposit a nano-scale zirconium oxide-diamond-like carbon composite film layer on the surface of the lens.

● The stainless steel sanitary pipeline direct quick-install sight glass is designed with a micro-spiral guide channel in the sealing ring groove, which will produce a local eddy current effect when the medium flows through.

● The stainless steel sanitary pipeline direct quick-install sight glass adopts a multi-layer composite sapphire-alumina ceramic material manufactured by a gradient sintering process, with a high-toughness matrix as the inner layer and an ultra-hard wear-resistant layer as the outer layer.

● The stainless steel sanitary pipeline direct quick-install sight glass integrates a micro-piezoelectric ceramic vibrator inside the sight glass body, and the lens produces nano-level amplitude vibration through ultrasonic vibration of a specific frequency.

● The stainless steel sanitary pipeline direct quick-install sight glass adopts an intelligent sealing ring made of shape memory alloy (SMA), which can automatically adjust the compression amount when the temperature changes.

● The stainless steel sanitary pipeline direct quick-install sight glass has a dual-channel argon protection system, which forms an inert gas barrier in the sight glass cavity, preventing both oxidation of the medium and fogging of the lens.

Application

Stainless steel sanitary pipeline straight-through quick-install sight glasses are widely used in the following industries: Food processing: monitor the state of food fluids to ensure that the production process is pollution-free. Beverage production: observe the flow of juice, dairy products, carbonated beverages, etc. Dairy industry: check the flow quality of dairy products such as milk and yogurt. Pharmaceutical industry: monitor the pipeline transportation process of liquid medicine, injection liquid, etc. Cosmetic manufacturing: observe the transportation status of pastes, emulsions and other materials. Fine chemicals: monitor the flow of high-purity chemical solutions. Biological fermentation: observe the flow of fermentation liquid and control the culture environment of bacteria.