| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Sanitary Polished Quick-install Constant Pressure Valve

The stainless steel sanitary quick-install constant pressure valve is designed to provide a fluid control solution that is both efficient and safe for the high-cleanliness industry. This valve is not just a simple control element, it is the crystallization of precision technology and strict hygiene standards. In industries such as food and pharmaceuticals, any slight contamination may cause serious problems in product quality and even endanger consumer health. Therefore, this valve uses high-grade 316L stainless steel material to ensure that it can resist corrosion and keep the fluid pure even in harsh environments. The quick-install design allows the valve to be quickly installed and removed, greatly improving production efficiency. It is also convenient for thorough cleaning and sterilization to meet strict hygiene requirements.

Working Principles

The working principle of the stainless steel sanitary quick-install constant pressure valve is based on the automatic adjustment mechanism of spring or pneumatic control, and the constant pressure in the pipeline is maintained by changing the valve core opening. First, when the fluid enters the valve body, the pressure acts on the diaphragm or piston assembly, pushing the internal spring to compress or release; secondly, the valve core automatically adjusts the opening according to the pressure change-when the pipeline pressure is higher than the set value, the valve core gradually opens and releases excess fluid to reduce pressure; when the pressure is lower than the set value, the spring or pneumatic actuator pushes the valve core to close, reducing the flow and increasing the pipeline pressure; finally, the valve maintains the stability of the set pressure in continuous dynamic adjustment, making the fluid delivery more stable and ensuring the normal operation of downstream equipment or process flow.

The options of the stainless steel sanitary quick-install constant pressure valve include:

Adjustment method: spring adjustment, pneumatic control.

Pressure setting range: different spring stiffness or pneumatic control range are optional.

Interface specification: quick installation (quick-install connector size is optional).

Sealing material: EPDM, PTFE, silicone, etc.

Surface treatment: optional polishing level (Ra value of internal and external surfaces).

Additional functions: with pressure gauge, optional feedback signal output, etc.

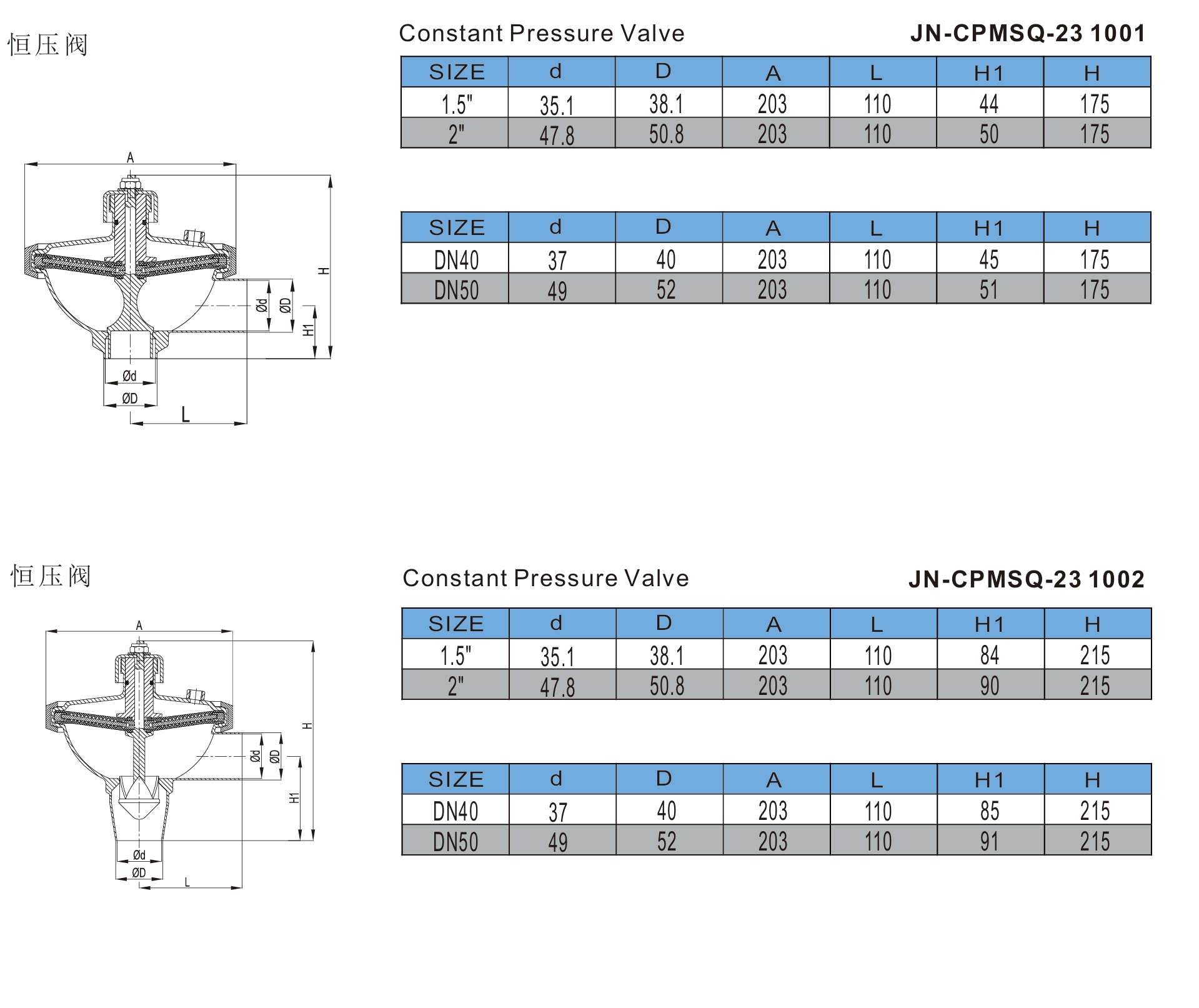

Specification Chart

Size | 1” to 2 ½ “ |

Material | SS304, SS316L |

Max. air pressure | 0 to 8 bar |

Max. product pressure | 0 to 10 bae |

Temperature | -10 °C to 140 °C |

End connections | Welded, threaded connection |

Seals and gasket | PTFE, EPDM,NBR |

Features

● The stainless steel sanitary quick-install constant pressure valve core adopts a fluid dynamics optimization design, which can automatically adjust the fluid channel shape according to the flow rate and pressure changes.

● The stainless steel sanitary quick-install constant pressure valve adopts a special alloy spring with lower hysteresis effect. It can quickly restore the set pressure under frequent switching and pressure fluctuations to ensure stable operation of the system.

● The stainless steel sanitary quick-install constant pressure valve has a back pressure compensation chamber design. When the upstream pressure fluctuates, the valve can instantly adjust the opening to prevent the pipeline pressure from overshooting or dropping.

● The stainless steel sanitary quick-install constant pressure valve is designed with a micron-level pressure relief channel between the valve seat and the valve core, which effectively prevents cavitation caused by sudden pressure drop and prevents bubbles from eroding the valve body and valve core.

● The stainless steel sanitary quick-install constant pressure valve adopts a double-layer diaphragm design, with the inner layer providing the main seal and the outer layer absorbing pressure shock, thereby increasing the life of the diaphragm and avoiding cracks or damage caused by long-term pressure.

● The key components of the stainless steel sanitary quick-install constant pressure valve have undergone nano-level surface treatment, which reduces the friction coefficient by more than 50%, effectively reducing the wear of the valve core and valve seat.

Application

Stainless steel sanitary quick-install constant pressure valve is widely used in the following industries: Food and beverage: constant pressure delivery system for dairy products, juice, and carbonated beverages. Pharmaceutical industry: pressure control of sterile liquid, injection, and purified water systems. Bioengineering: constant pressure regulation of fermentation tanks and culture medium delivery pipelines. Cosmetics industry: uniform delivery systems for emulsions, flavors, gels, etc. Fine chemicals: constant pressure delivery and reflux control of high-purity reagents, solvents, etc. Beer brewing: stable pressure of wort, fermentation liquid, and filtration systems.

Working Principles

The working principle of the stainless steel sanitary quick-install constant pressure valve is based on the automatic adjustment mechanism of spring or pneumatic control, and the constant pressure in the pipeline is maintained by changing the valve core opening. First, when the fluid enters the valve body, the pressure acts on the diaphragm or piston assembly, pushing the internal spring to compress or release; secondly, the valve core automatically adjusts the opening according to the pressure change-when the pipeline pressure is higher than the set value, the valve core gradually opens and releases excess fluid to reduce pressure; when the pressure is lower than the set value, the spring or pneumatic actuator pushes the valve core to close, reducing the flow and increasing the pipeline pressure; finally, the valve maintains the stability of the set pressure in continuous dynamic adjustment, making the fluid delivery more stable and ensuring the normal operation of downstream equipment or process flow.

The options of the stainless steel sanitary quick-install constant pressure valve include:

Adjustment method: spring adjustment, pneumatic control.

Pressure setting range: different spring stiffness or pneumatic control range are optional.

Interface specification: quick installation (quick-install connector size is optional).

Sealing material: EPDM, PTFE, silicone, etc.

Surface treatment: optional polishing level (Ra value of internal and external surfaces).

Additional functions: with pressure gauge, optional feedback signal output, etc.

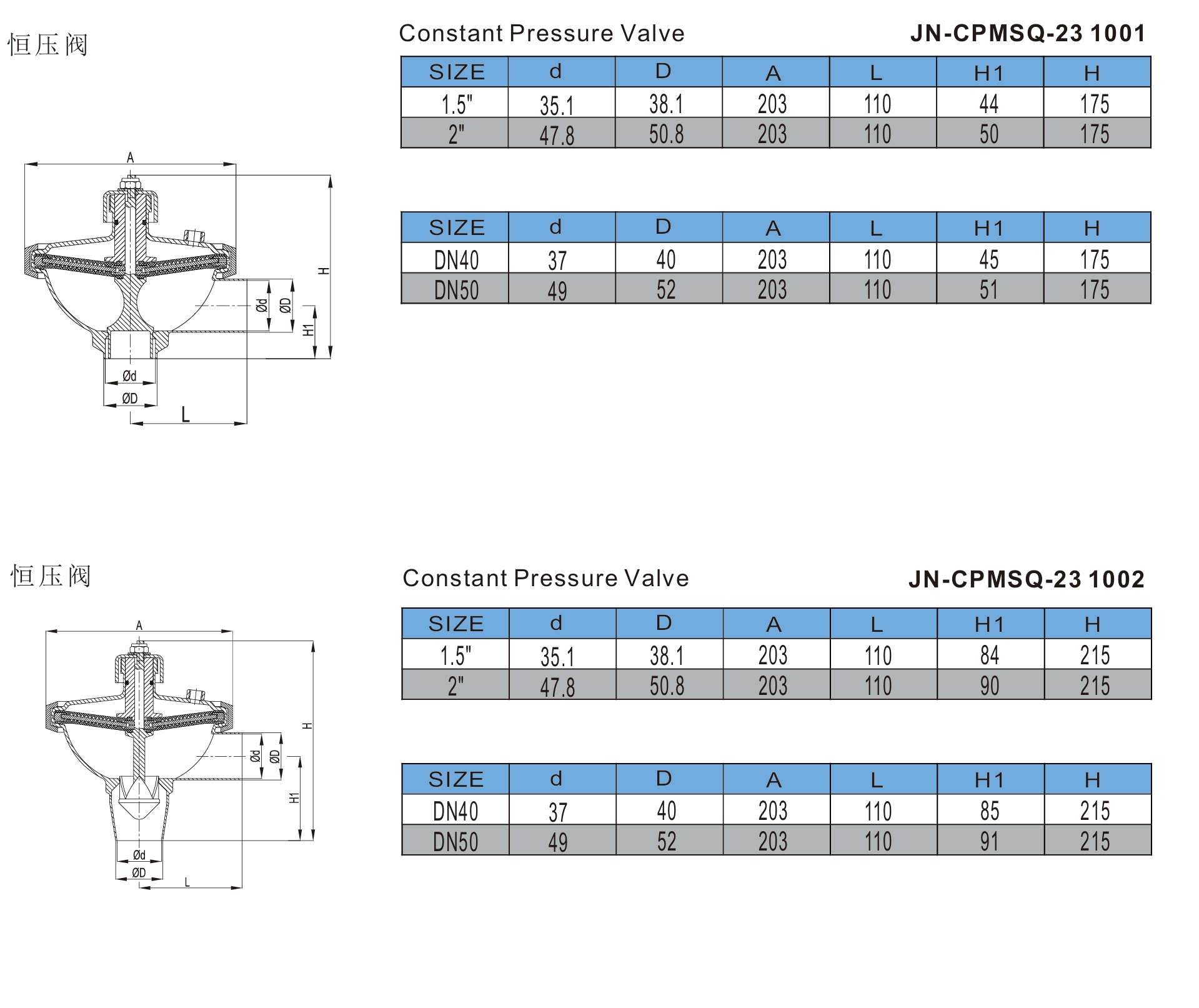

Specification Chart

Size | 1” to 2 ½ “ |

Material | SS304, SS316L |

Max. air pressure | 0 to 8 bar |

Max. product pressure | 0 to 10 bae |

Temperature | -10 °C to 140 °C |

End connections | Welded, threaded connection |

Seals and gasket | PTFE, EPDM,NBR |

Features

● The stainless steel sanitary quick-install constant pressure valve core adopts a fluid dynamics optimization design, which can automatically adjust the fluid channel shape according to the flow rate and pressure changes.

● The stainless steel sanitary quick-install constant pressure valve adopts a special alloy spring with lower hysteresis effect. It can quickly restore the set pressure under frequent switching and pressure fluctuations to ensure stable operation of the system.

● The stainless steel sanitary quick-install constant pressure valve has a back pressure compensation chamber design. When the upstream pressure fluctuates, the valve can instantly adjust the opening to prevent the pipeline pressure from overshooting or dropping.

● The stainless steel sanitary quick-install constant pressure valve is designed with a micron-level pressure relief channel between the valve seat and the valve core, which effectively prevents cavitation caused by sudden pressure drop and prevents bubbles from eroding the valve body and valve core.

● The stainless steel sanitary quick-install constant pressure valve adopts a double-layer diaphragm design, with the inner layer providing the main seal and the outer layer absorbing pressure shock, thereby increasing the life of the diaphragm and avoiding cracks or damage caused by long-term pressure.

● The key components of the stainless steel sanitary quick-install constant pressure valve have undergone nano-level surface treatment, which reduces the friction coefficient by more than 50%, effectively reducing the wear of the valve core and valve seat.

Application

Stainless steel sanitary quick-install constant pressure valve is widely used in the following industries: Food and beverage: constant pressure delivery system for dairy products, juice, and carbonated beverages. Pharmaceutical industry: pressure control of sterile liquid, injection, and purified water systems. Bioengineering: constant pressure regulation of fermentation tanks and culture medium delivery pipelines. Cosmetics industry: uniform delivery systems for emulsions, flavors, gels, etc. Fine chemicals: constant pressure delivery and reflux control of high-purity reagents, solvents, etc. Beer brewing: stable pressure of wort, fermentation liquid, and filtration systems.