| Availability: | |

|---|---|

| Quantity: | |

JONENG

7307290000

Stainless Steel Sanitary Polishing Butt Weld Pipe Living Union

Stainless steel sanitary fittings are designed to achieve efficient, safe and sustainable fluid connections, especially in industries with extremely high sanitation standards. Its core goal is to ensure that the fittings have excellent corrosion resistance, high temperature resistance and pollution resistance by using stainless steel materials, so as to avoid contamination by any harmful substances or microorganisms and ensure the purity of the fluid. In addition, the design is easy to disassemble, clean and disinfect, which reduces the possibility of bacterial growth, ensures safety and reliability in the production process, and is particularly suitable for pipeline connections in the food processing, pharmaceutical and beverage industries.

Working Principles

The working principle of stainless steel sanitary fittings is based on the sealing of pipeline connections and the pollution-free nature of fluid transmission. The pipes at both ends of the joint are precisely connected and tightly fixed by connection methods such as clamps, welding or threads. The joint part has a specially designed sealing ring to ensure that leakage can be effectively prevented under high pressure or high temperature environment. When the fluid passes through the joint, the sealing ring ensures that there is no leakage, and prevents any microorganisms or contaminants from entering the fluid, ensuring the purity and safety of the fluid.

The options of stainless steel sanitary joints include:

Connection method: clamp, welding, thread, flange.

Sealing material: EPDM, PTFE, Viton.

Size: customized according to the pipe diameter.

Material: 304 stainless steel, 316L stainless steel.

Surface treatment: smooth, brushed, polished.

Type: straight, elbow, tee, reducer.

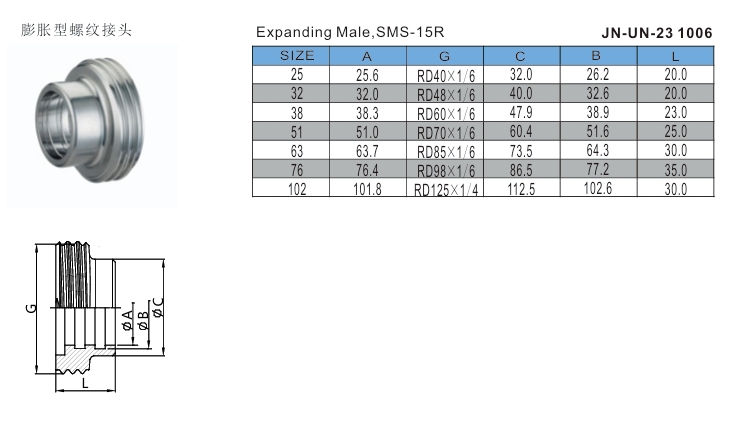

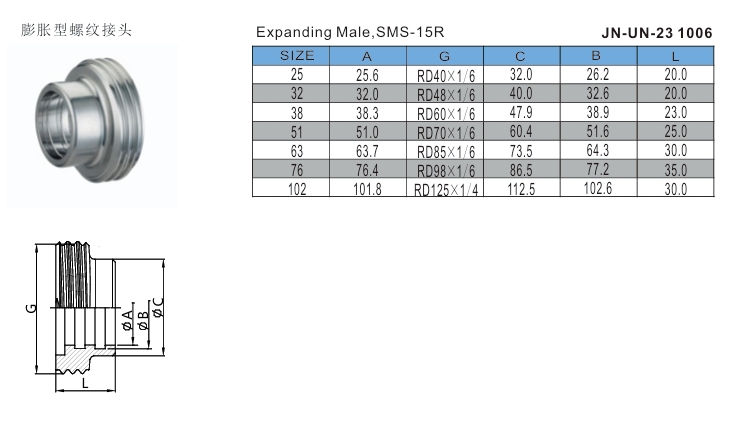

Specification Chart

Size | ½ “ to 6” |

Material | SS304, SS316 |

Gaskets or seals | Silicone, PTFE, EPDM, viton |

Pressure | - 6 to 40 bars |

Temperature | -40C to 150C |

Standard | SMS,DIN, 3A,RJT,BSM,IDF.. |

Features

● The inner wall of the stainless steel sanitary connector is mirror-polished to make the inner surface of the pipe smoother. This treatment can effectively reduce the possibility of bacteria, dirt and sediment adhesion, thereby improving the efficiency of pipe cleaning.

● The stainless steel sanitary connector adopts antibacterial coating technology, which can inhibit the growth of bacteria and mold and reduce pollution caused by long-term use.

● The stainless steel sanitary connector is embedded with an intelligent temperature sensor in the design, which can monitor the temperature changes in the pipe in real time.

● The stainless steel sanitary connector adopts a quick disassembly design and is equipped with convenient clamps or quick-release connectors, which can greatly improve the efficiency of disassembly and maintenance.

● The stainless steel sanitary connector adopts double sealing technology, and sealing devices are respectively provided on the outside and inside to effectively prevent fluid leakage.

● The stainless steel sanitary connector adopts an anti-static design, which reduces the risk of static electricity accumulation by coating a conductive layer on the surface of the connector or using conductive materials.

Application

Stainless steel sanitary life joints are widely used in the following industries: Food processing: connecting pipelines to ensure the purity and safety of food fluids. Pharmaceutical industry: ensuring the sterility and sealing of pipelines during drug production. Beverage industry: used for liquid transportation to avoid pollution and ensure product quality. Cosmetics industry: ensuring that fluid transmission during cosmetics production is pollution-free. Dairy industry: Maintain high hygiene standards during dairy processing. Chemical industry: Avoid cross contamination and corrosion problems during fluid transmission. Water treatment industry: Used for pipe connection during water purification to prevent contamination.

Working Principles

The working principle of stainless steel sanitary fittings is based on the sealing of pipeline connections and the pollution-free nature of fluid transmission. The pipes at both ends of the joint are precisely connected and tightly fixed by connection methods such as clamps, welding or threads. The joint part has a specially designed sealing ring to ensure that leakage can be effectively prevented under high pressure or high temperature environment. When the fluid passes through the joint, the sealing ring ensures that there is no leakage, and prevents any microorganisms or contaminants from entering the fluid, ensuring the purity and safety of the fluid.

The options of stainless steel sanitary joints include:

Connection method: clamp, welding, thread, flange.

Sealing material: EPDM, PTFE, Viton.

Size: customized according to the pipe diameter.

Material: 304 stainless steel, 316L stainless steel.

Surface treatment: smooth, brushed, polished.

Type: straight, elbow, tee, reducer.

Specification Chart

Size | ½ “ to 6” |

Material | SS304, SS316 |

Gaskets or seals | Silicone, PTFE, EPDM, viton |

Pressure | - 6 to 40 bars |

Temperature | -40C to 150C |

Standard | SMS,DIN, 3A,RJT,BSM,IDF.. |

Features

● The inner wall of the stainless steel sanitary connector is mirror-polished to make the inner surface of the pipe smoother. This treatment can effectively reduce the possibility of bacteria, dirt and sediment adhesion, thereby improving the efficiency of pipe cleaning.

● The stainless steel sanitary connector adopts antibacterial coating technology, which can inhibit the growth of bacteria and mold and reduce pollution caused by long-term use.

● The stainless steel sanitary connector is embedded with an intelligent temperature sensor in the design, which can monitor the temperature changes in the pipe in real time.

● The stainless steel sanitary connector adopts a quick disassembly design and is equipped with convenient clamps or quick-release connectors, which can greatly improve the efficiency of disassembly and maintenance.

● The stainless steel sanitary connector adopts double sealing technology, and sealing devices are respectively provided on the outside and inside to effectively prevent fluid leakage.

● The stainless steel sanitary connector adopts an anti-static design, which reduces the risk of static electricity accumulation by coating a conductive layer on the surface of the connector or using conductive materials.

Application

Stainless steel sanitary life joints are widely used in the following industries: Food processing: connecting pipelines to ensure the purity and safety of food fluids. Pharmaceutical industry: ensuring the sterility and sealing of pipelines during drug production. Beverage industry: used for liquid transportation to avoid pollution and ensure product quality. Cosmetics industry: ensuring that fluid transmission during cosmetics production is pollution-free. Dairy industry: Maintain high hygiene standards during dairy processing. Chemical industry: Avoid cross contamination and corrosion problems during fluid transmission. Water treatment industry: Used for pipe connection during water purification to prevent contamination.