| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary quick-install level valve has a simple design, ensuring efficient and accurate liquid level control, and is suitable for food, medicine and other industries. The stainless steel sanitary quick-install level valve is usually used in the pipeline system of the food, beverage, pharmaceutical and other industries, and is installed on the inlet and outlet pipes of liquid storage tanks, reactors, mixing tanks and other equipment. It ensures that the liquid flows within the predetermined range by accurately controlling the liquid level, avoiding the impact of ultra-high or ultra-low liquid levels on the production process. In the pipeline system, the valve can be quickly disassembled and cleaned to ensure hygiene standards, while effectively preventing pollutants from entering the system and ensuring product quality. The stainless steel sanitary quick-install level valve mainly has the following types: float level valve, pressure level valve, electronic level valve, manual level valve.

JONENG

8481804090

Stainless Steel Sanitary Quick-install Level Valve For Chemical Industry

The stainless steel sanitary quick-install level valve is designed to solve the problems of liquid level control and system cleaning in high-demand environments. Its unique quick-install structure makes installation, disassembly and cleaning easier and more efficient, avoiding the cumbersome cleaning and maintenance process of traditional valves, and reducing manual operation and time costs. In the demanding food and pharmaceutical industries, avoiding cross contamination is key, and this valve, with its dead-angle-free design, ensures that no residue accumulates, ensuring the purity and safety of the product. In addition, the liquid level valve accurately controls the flow of liquid, maintains stable operation of the equipment, optimizes the production process, reduces system failures or losses caused by liquid level fluctuations, and further improves production efficiency and product quality.

Working Principles

The working principle of the stainless steel sanitary quick-install liquid level valve usually relies on the float or pressure sensing principle. Taking the float type liquid level valve as an example, when the liquid flows in a storage tank or pipeline, the float will float up and down as the liquid level changes. When the liquid level rises, the float rises with it, pushing the valve to close or adjust; when the liquid level drops, the float sinks, and the valve opens or adjusts to the desired state. During the whole process, the valve automatically adjusts the opening and closing according to the action of the float to ensure that the liquid level is always kept within the predetermined range to prevent liquid overflow or too low a level.

The options for the stainless steel sanitary quick-install liquid level valve include:

Connection method: You can choose quick-install clamp connection, threaded connection, etc.

Float material: stainless steel, polypropylene and other materials.

Valve body design: spherical, angular and other different structural designs.

Control method: float control, pressure control, electronic control, etc.

Size and pressure level: customized according to system requirements.

Sealing material: silicone, PTFE, etc. to ensure sealing effect.

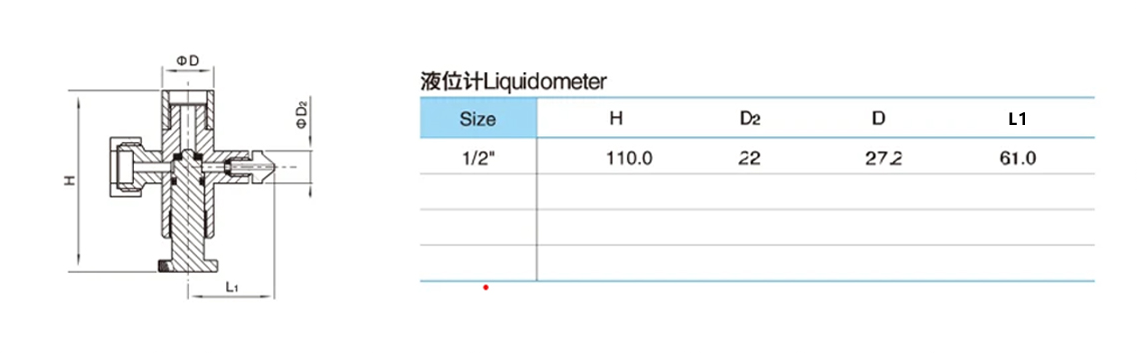

Specification Chart

Size | ½ "to ¾ " |

Material | AISI 304, AISI316L |

End connections | Threaded, clamp |

Max temprature | -20 °C to 135 °C |

Max pressure | Vaccum to 10 bar |

Seals and gasket | Silicon, EPDM |

Features

● The stainless steel sanitary quick-install level valve adopts a double sealing structure to provide additional sealing protection between the valve body and the float. This design can effectively prevent liquid leakage, improve the safety of the valve, ensure the long-term stable operation of the system, and reduce the frequency of maintenance.

● The stainless steel sanitary quick-install level valve is designed with a unique self-cleaning structure inside, which can automatically flush the inner wall of the valve when the liquid flows, effectively avoiding dirt accumulation. This reduces cleaning time and labor costs, and improves production efficiency and hygiene standards.

● The surface of the stainless steel sanitary quick-install level valve is treated with a special high-temperature anti-corrosion coating, which can be used for a long time in a high temperature environment without corrosion. It increases the service life under extreme working conditions and reduces maintenance costs.

● The unique float pressure adjustment system of the stainless steel sanitary quick-install level valve allows users to adjust the buoyancy of the float according to needs and optimize the accuracy of liquid level control. This technology improves the adaptability of the system and can handle a variety of liquids with different viscosities and pressures.

● The stainless steel sanitary quick-install level valve body and connection parts adopt a dead-angle-free design to ensure that every part can be completely cleaned. The no-dead-angle design reduces health risks, avoids bacteria or material residues, and improves the safety of the entire pipeline system.

● The stainless steel sanitary quick-install level valve is combined with precision electronic sensors to monitor liquid level changes in real time and provide feedback. This technology makes liquid level control more accurate, avoids errors in manual operation, and improves the level of automation of operation.

Application

Stainless steel sanitary quick-install level valves are usually used in the following industries: Food industry: ensure accurate liquid level control, avoid contamination, and meet hygiene standards. Beverage industry: maintain stable liquid level, improve production efficiency, and ensure beverage quality. Pharmaceutical industry: precise liquid level control, prevent cross contamination, and ensure safe drug production. Chemical industry: strong corrosion resistance, adapt to complex liquid environments, and ensure safe production. Dairy industry: prevent liquid leakage, ensure stable liquid level, and meet hygiene requirements. Cosmetics industry: ensure accurate control of raw material liquid level to meet high hygiene requirements.

Working Principles

The working principle of the stainless steel sanitary quick-install liquid level valve usually relies on the float or pressure sensing principle. Taking the float type liquid level valve as an example, when the liquid flows in a storage tank or pipeline, the float will float up and down as the liquid level changes. When the liquid level rises, the float rises with it, pushing the valve to close or adjust; when the liquid level drops, the float sinks, and the valve opens or adjusts to the desired state. During the whole process, the valve automatically adjusts the opening and closing according to the action of the float to ensure that the liquid level is always kept within the predetermined range to prevent liquid overflow or too low a level.

The options for the stainless steel sanitary quick-install liquid level valve include:

Connection method: You can choose quick-install clamp connection, threaded connection, etc.

Float material: stainless steel, polypropylene and other materials.

Valve body design: spherical, angular and other different structural designs.

Control method: float control, pressure control, electronic control, etc.

Size and pressure level: customized according to system requirements.

Sealing material: silicone, PTFE, etc. to ensure sealing effect.

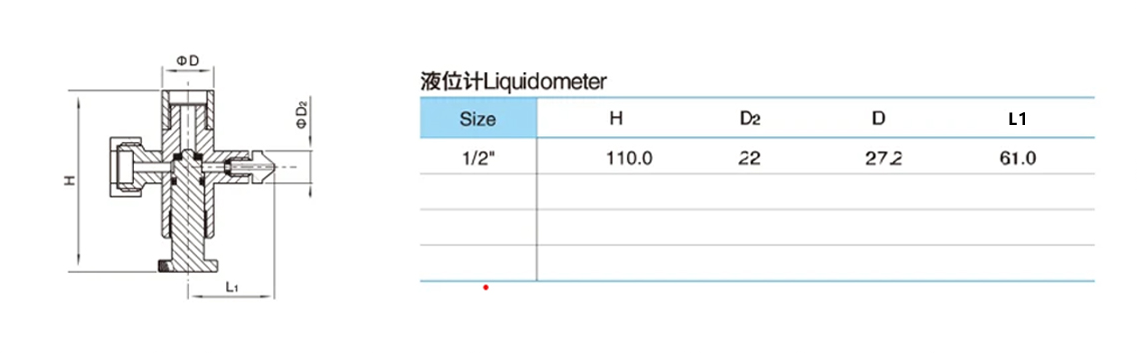

Specification Chart

Size | ½ "to ¾ " |

Material | AISI 304, AISI316L |

End connections | Threaded, clamp |

Max temprature | -20 °C to 135 °C |

Max pressure | Vaccum to 10 bar |

Seals and gasket | Silicon, EPDM |

Features

● The stainless steel sanitary quick-install level valve adopts a double sealing structure to provide additional sealing protection between the valve body and the float. This design can effectively prevent liquid leakage, improve the safety of the valve, ensure the long-term stable operation of the system, and reduce the frequency of maintenance.

● The stainless steel sanitary quick-install level valve is designed with a unique self-cleaning structure inside, which can automatically flush the inner wall of the valve when the liquid flows, effectively avoiding dirt accumulation. This reduces cleaning time and labor costs, and improves production efficiency and hygiene standards.

● The surface of the stainless steel sanitary quick-install level valve is treated with a special high-temperature anti-corrosion coating, which can be used for a long time in a high temperature environment without corrosion. It increases the service life under extreme working conditions and reduces maintenance costs.

● The unique float pressure adjustment system of the stainless steel sanitary quick-install level valve allows users to adjust the buoyancy of the float according to needs and optimize the accuracy of liquid level control. This technology improves the adaptability of the system and can handle a variety of liquids with different viscosities and pressures.

● The stainless steel sanitary quick-install level valve body and connection parts adopt a dead-angle-free design to ensure that every part can be completely cleaned. The no-dead-angle design reduces health risks, avoids bacteria or material residues, and improves the safety of the entire pipeline system.

● The stainless steel sanitary quick-install level valve is combined with precision electronic sensors to monitor liquid level changes in real time and provide feedback. This technology makes liquid level control more accurate, avoids errors in manual operation, and improves the level of automation of operation.

Application

Stainless steel sanitary quick-install level valves are usually used in the following industries: Food industry: ensure accurate liquid level control, avoid contamination, and meet hygiene standards. Beverage industry: maintain stable liquid level, improve production efficiency, and ensure beverage quality. Pharmaceutical industry: precise liquid level control, prevent cross contamination, and ensure safe drug production. Chemical industry: strong corrosion resistance, adapt to complex liquid environments, and ensure safe production. Dairy industry: prevent liquid leakage, ensure stable liquid level, and meet hygiene requirements. Cosmetics industry: ensure accurate control of raw material liquid level to meet high hygiene requirements.