| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Sanitary Quick-install Pipe Straight-through Sight Glass

The stainless steel sanitary quick-install pipe straight-through sight glass is designed to solve the problem that the fluid state cannot be observed intuitively in traditional pipeline inspections. It allows operators to directly observe the flow, color, bubbles and other characteristics of the fluid in the pipeline through a transparent window, and promptly detect problems such as blockage, leakage or contamination that may exist in the pipeline. In addition, the quick-install design makes installation and disassembly more efficient, especially suitable for environments that require frequent cleaning, maintenance or inspection, to ensure product quality and stability of the production process.

Working Principles

The working principle of the stainless steel sanitary quick-install pipe straight-through sight glass mainly relies on its transparent window and quick installation design. The sight glass is installed at the reserved interface of the pipeline system and is quickly connected through the quick-install clamp. When the fluid flows in the pipeline, the operator can observe the color, bubbles, impurities and other characteristics of the fluid through the window to judge the state of the fluid. With this design, the operator can promptly detect abnormal fluid flow and take timely measures to adjust it to ensure the stability of the production process and the quality of the fluid.

The options of the stainless steel sanitary quick-install pipe straight-through sight glass include:

Transparent window material: glass or polycarbonate.

Built-in lighting system: LED light or fiber optic lighting.

Protective cover: metal or plastic protective cover.

Angle adjustment: adjustable window angle.

Built-in valve: valve can be equipped to isolate pipeline fluid.

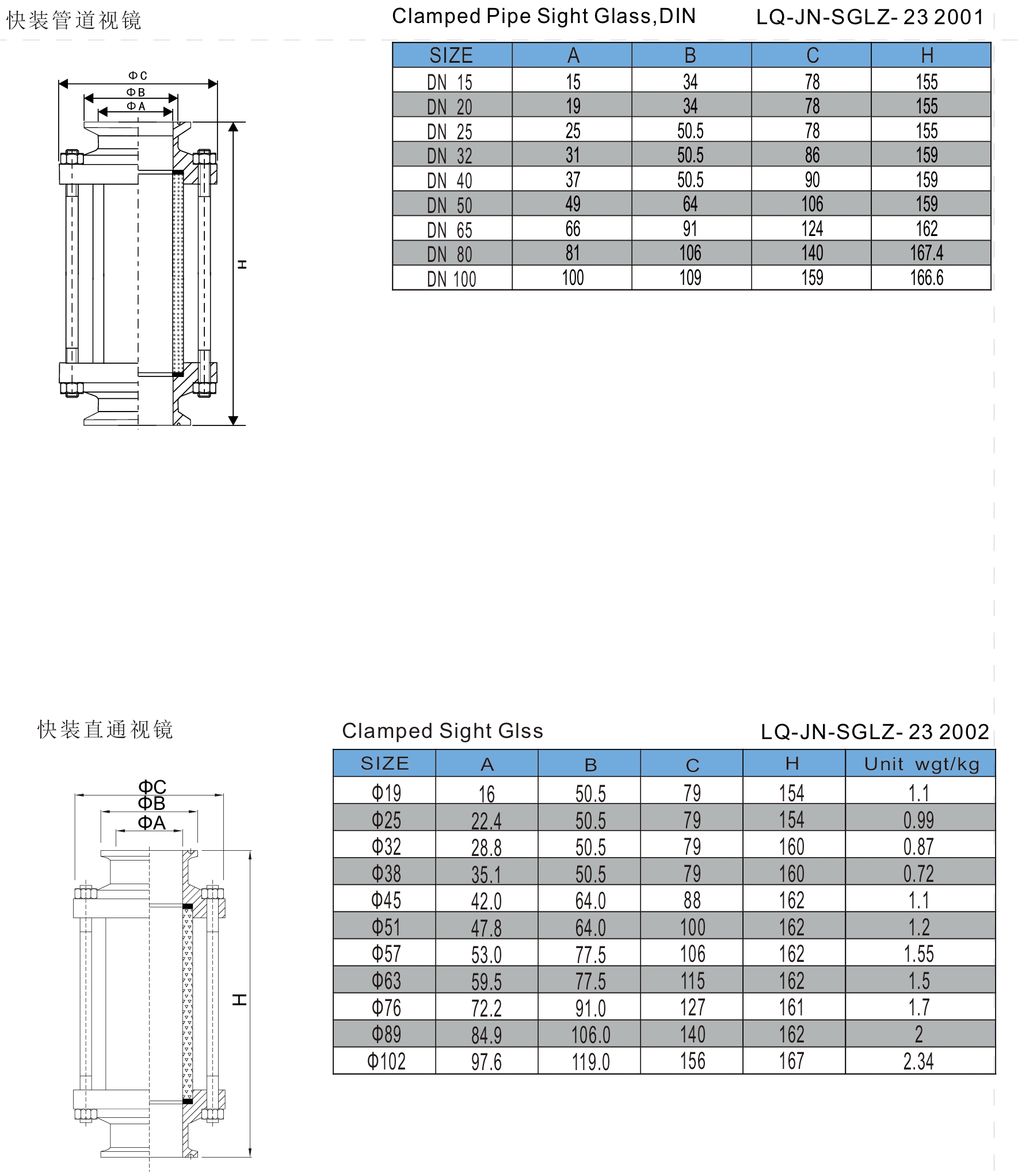

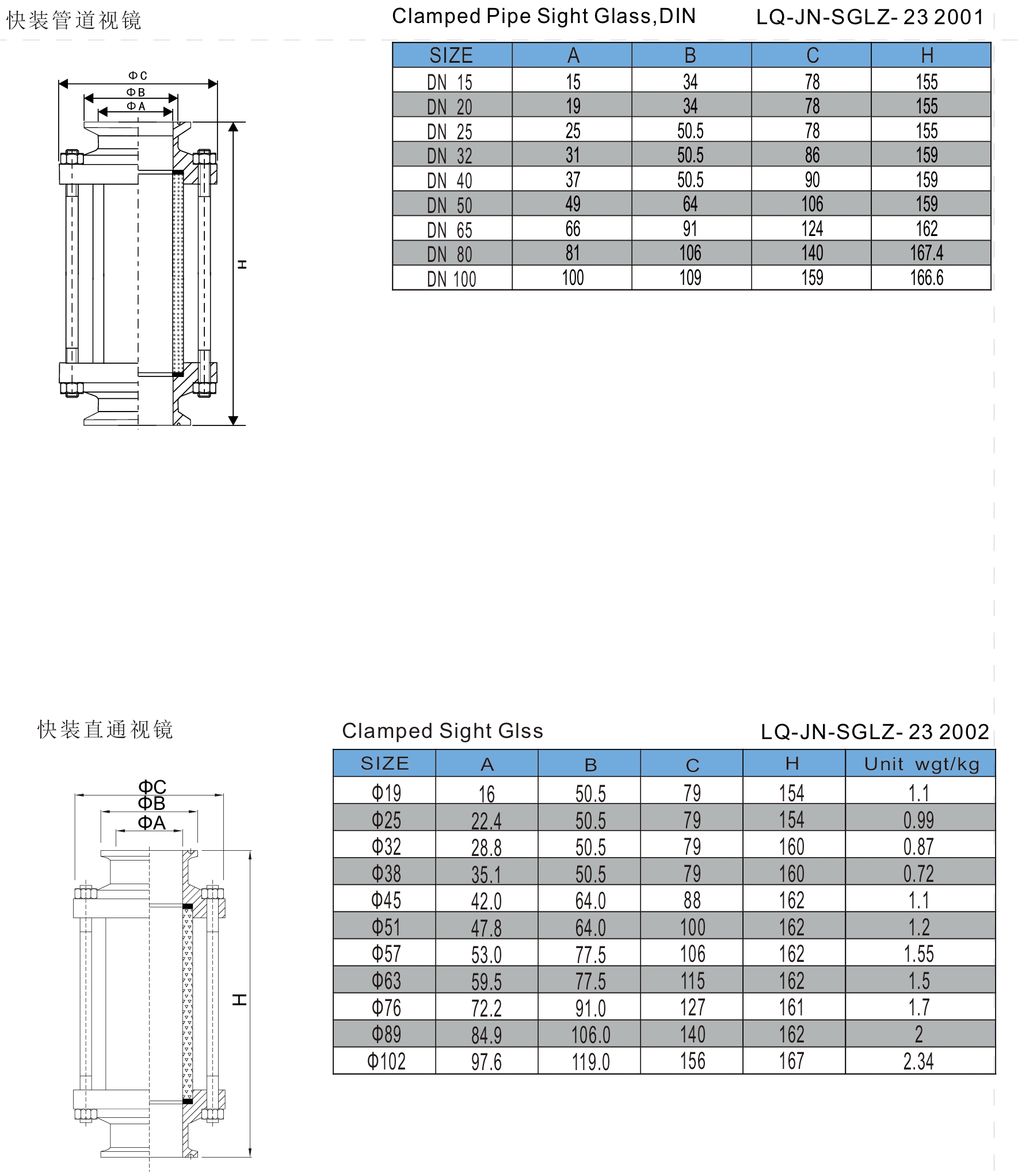

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary quick-install pipe straight-through sight glass can be equipped with a built-in automatic cleaning system to regularly clean the window through air flow or liquid flow to prevent the accumulation of dirt, grease or other substances.

● The stainless steel sanitary quick-install pipe straight-through sight glass uses special UV-resistant materials, which can effectively block UV radiation and avoid adverse effects on the fluid due to UV radiation.

● The stainless steel sanitary quick-install pipe straight-through sight glass integrates a temperature monitoring system, which can monitor the temperature of the fluid in the pipeline in real time, and the temperature data can be fed back to the central control system.

● The angle of the stainless steel sanitary quick-install pipe straight-through sight glass can be adjusted according to needs to adapt to different installation environments and observation angles.

● The structure of the stainless steel sanitary quick-install pipe straight-through sight glass adopts a reinforced design to withstand the high-pressure environment in the pipeline system and ensure the safety and stability of the system.

● The stainless steel sanitary quick-install pipe straight-through sight glass uses multi-layer explosion-proof glass material to prevent the window from breaking under high pressure environment and provide additional safety protection.

Application

Stainless steel sanitary bracket with base is widely used in the following industries: Food industry: ensure that the fluid in the production process meets the hygiene requirements and avoids contamination. Pharmaceutical industry: monitor the quality of liquid medicine to ensure that the production environment is pollution-free and meets the standards. Beverage industry: check the flow state of beverages to ensure that there are no foreign matter and impurities. Cosmetic industry: observe the quality of fluids in the production process of cosmetics to ensure that there is no contamination. Chemical industry: monitor the chemical reaction process to ensure that the chemicals flow normally. Water treatment industry: observe the flow of water quality and monitor the status of the water treatment system.

Working Principles

The working principle of the stainless steel sanitary quick-install pipe straight-through sight glass mainly relies on its transparent window and quick installation design. The sight glass is installed at the reserved interface of the pipeline system and is quickly connected through the quick-install clamp. When the fluid flows in the pipeline, the operator can observe the color, bubbles, impurities and other characteristics of the fluid through the window to judge the state of the fluid. With this design, the operator can promptly detect abnormal fluid flow and take timely measures to adjust it to ensure the stability of the production process and the quality of the fluid.

The options of the stainless steel sanitary quick-install pipe straight-through sight glass include:

Transparent window material: glass or polycarbonate.

Built-in lighting system: LED light or fiber optic lighting.

Protective cover: metal or plastic protective cover.

Angle adjustment: adjustable window angle.

Built-in valve: valve can be equipped to isolate pipeline fluid.

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary quick-install pipe straight-through sight glass can be equipped with a built-in automatic cleaning system to regularly clean the window through air flow or liquid flow to prevent the accumulation of dirt, grease or other substances.

● The stainless steel sanitary quick-install pipe straight-through sight glass uses special UV-resistant materials, which can effectively block UV radiation and avoid adverse effects on the fluid due to UV radiation.

● The stainless steel sanitary quick-install pipe straight-through sight glass integrates a temperature monitoring system, which can monitor the temperature of the fluid in the pipeline in real time, and the temperature data can be fed back to the central control system.

● The angle of the stainless steel sanitary quick-install pipe straight-through sight glass can be adjusted according to needs to adapt to different installation environments and observation angles.

● The structure of the stainless steel sanitary quick-install pipe straight-through sight glass adopts a reinforced design to withstand the high-pressure environment in the pipeline system and ensure the safety and stability of the system.

● The stainless steel sanitary quick-install pipe straight-through sight glass uses multi-layer explosion-proof glass material to prevent the window from breaking under high pressure environment and provide additional safety protection.

Application

Stainless steel sanitary bracket with base is widely used in the following industries: Food industry: ensure that the fluid in the production process meets the hygiene requirements and avoids contamination. Pharmaceutical industry: monitor the quality of liquid medicine to ensure that the production environment is pollution-free and meets the standards. Beverage industry: check the flow state of beverages to ensure that there are no foreign matter and impurities. Cosmetic industry: observe the quality of fluids in the production process of cosmetics to ensure that there is no contamination. Chemical industry: monitor the chemical reaction process to ensure that the chemicals flow normally. Water treatment industry: observe the flow of water quality and monitor the status of the water treatment system.