| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary pressure reducing valve is a valve designed for high-cleanliness environments. It is made of stainless steel and has the characteristics of corrosion resistance and high temperature resistance. It ensures stable pressure in the system by accurately adjusting the fluid pressure. Stainless steel sanitary pressure reducing valves are usually used in pipeline systems that require precise control of fluid pressure, especially in high-cleanliness industries such as food, pharmaceuticals, and bioengineering. They are usually installed at the entrance of the pipeline or in the main water supply pipeline. Common types of stainless steel sanitary pressure reducing valves include: spring-loaded pressure reducing valves, diaphragm-type pressure reducing valves, piston-type pressure reducing valves, straight-through pressure reducing valves, angle-type pressure reducing valves, and automatic regulating pressure reducing valves.

JONENG

8481804090

Stainless Steel Sanitary Quick-release Pressure Reducing Valve For Food

The stainless steel sanitary pressure reducing valve is designed to accurately control pressure fluctuations in the pipeline system to ensure the stability and safety of system operation. In a high-cleanliness environment, it not only prevents equipment damage through pressure adjustment, but also avoids negative effects on product quality when fluid pressure fluctuates. For example, in the food or pharmaceutical industry, high pressure may cause damage to the solution quality or premature wear of equipment. The pressure reducing valve protects the long-term operation of the system by maintaining a stable pressure. In addition, the pressure reducing valve can also reduce energy loss and avoid excessive energy consumption caused by excessive pressure, especially in processes that require high-precision pressure control, which can effectively improve production efficiency and ensure the efficient operation and compliance of the entire fluid delivery system.

Working Principles

The working principle of the stainless steel sanitary pressure reducing valve is based on pressure control and automatic adjustment mechanism. First, the fluid enters the pressure reducing valve at high pressure, and the spring or diaphragm in the valve body generates a reaction force through interaction with the fluid pressure. When the fluid pressure is too high, the control element (such as the piston or diaphragm) in the valve will be pushed, pushing the valve open, allowing part of the fluid to pass through the bypass pipe to reduce the fluid pressure. As the pressure decreases, the valve automatically adjusts to maintain a stable output pressure. When the fluid flow increases or the external pressure changes, the regulating element inside the pressure reducing valve will make corresponding adjustments to ensure that the pressure of the fluid output is always kept within the set range.

The options for stainless steel sanitary pressure reducing valves include:

Type: direct-acting, pilot, diaphragm, piston, proportional, back pressure regulating valve.

Pressure range: low pressure, medium pressure, high pressure, to meet the needs of different working conditions.

Connection methods: thread, clamp, flange, welding, to meet different installation requirements.

Material: 304 or 316 stainless steel, 316 has better corrosion resistance.

Surface treatment: polishing, passivation, improve hygiene level and corrosion resistance.

Additional functions: with pressure gauge, adjustable pressure, shockproof design, etc.

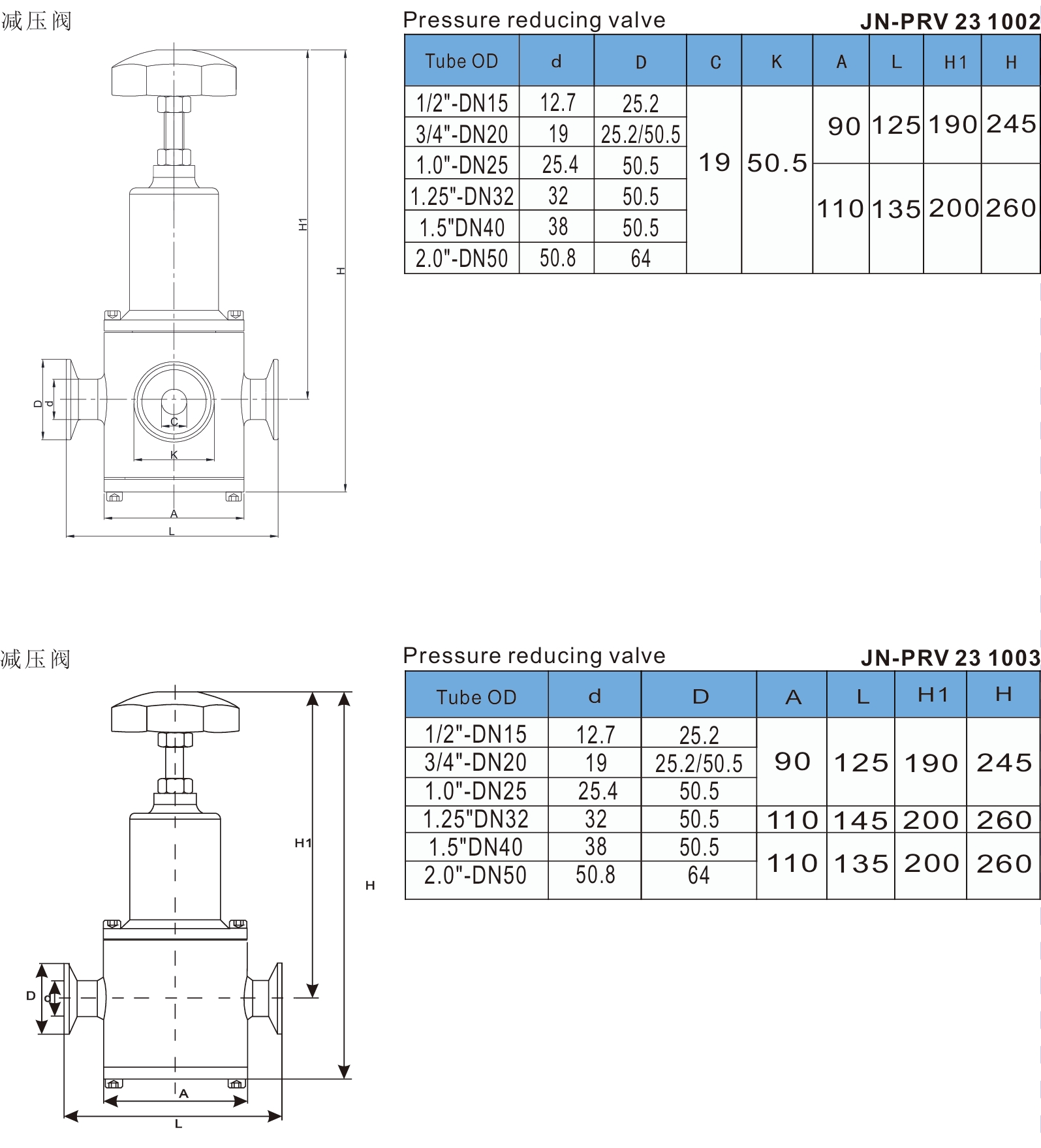

Specification Chart

Material | AISI304, AISI316L |

Size | 1" to 2" |

Seals | PTFE, EPDM, Viton |

End connections | Sanitary clamp |

Maximum pressure | 0 to 10 bar |

Maximum temperature | -15 °C to 148 °C |

Features

● The stainless steel sanitary pressure reducing valve has a built-in micro-filter that can effectively intercept impurities in the fluid and prevent them from entering the valve body and pipeline system.

● The stainless steel sanitary pressure reducing valve has an automatic compensation function, which can adjust the pressure setting value in real time to cope with flow fluctuations or changes in the external environment.

● The stainless steel sanitary pressure reducing valve adopts a double sealing structure, and the inner and outer sealing rings play different protective roles respectively, enhancing the sealing performance of the valve.

● The stainless steel sanitary pressure reducing valve integrates intelligent sensors and control systems, supports remote monitoring of valve status and remote adjustment.

● The stainless steel sanitary pressure reducing valve can adjust the output pressure very accurately through the fine-tuning spiral adjustment device to ensure stability.

● The stainless steel sanitary pressure reducing valve adopts a specially designed flow channel and shock absorbing device to significantly reduce the noise of the valve under low flow conditions.

Application

Stainless steel sanitary pressure reducing valves are widely used in the following industries: Food industry: ensure fluid stability, prevent pollution, and meet hygiene requirements. Pharmaceutical industry: accurately control pressure, ensure a sterile environment, and ensure product quality. Bioengineering: stabilize pressure and adapt to high cleanliness and special process requirements. Chemical industry: prevent high pressure from causing pipeline rupture, ensure safety and stability. Beverage industry: control fluid pressure to prevent affecting beverage quality and production process. Dairy industry: stabilize pipeline pressure, ensure fluid safety, and do not affect product quality. Medical industry: Ensure stable pipeline pressure to avoid contamination or equipment damage.

Working Principles

The working principle of the stainless steel sanitary pressure reducing valve is based on pressure control and automatic adjustment mechanism. First, the fluid enters the pressure reducing valve at high pressure, and the spring or diaphragm in the valve body generates a reaction force through interaction with the fluid pressure. When the fluid pressure is too high, the control element (such as the piston or diaphragm) in the valve will be pushed, pushing the valve open, allowing part of the fluid to pass through the bypass pipe to reduce the fluid pressure. As the pressure decreases, the valve automatically adjusts to maintain a stable output pressure. When the fluid flow increases or the external pressure changes, the regulating element inside the pressure reducing valve will make corresponding adjustments to ensure that the pressure of the fluid output is always kept within the set range.

The options for stainless steel sanitary pressure reducing valves include:

Type: direct-acting, pilot, diaphragm, piston, proportional, back pressure regulating valve.

Pressure range: low pressure, medium pressure, high pressure, to meet the needs of different working conditions.

Connection methods: thread, clamp, flange, welding, to meet different installation requirements.

Material: 304 or 316 stainless steel, 316 has better corrosion resistance.

Surface treatment: polishing, passivation, improve hygiene level and corrosion resistance.

Additional functions: with pressure gauge, adjustable pressure, shockproof design, etc.

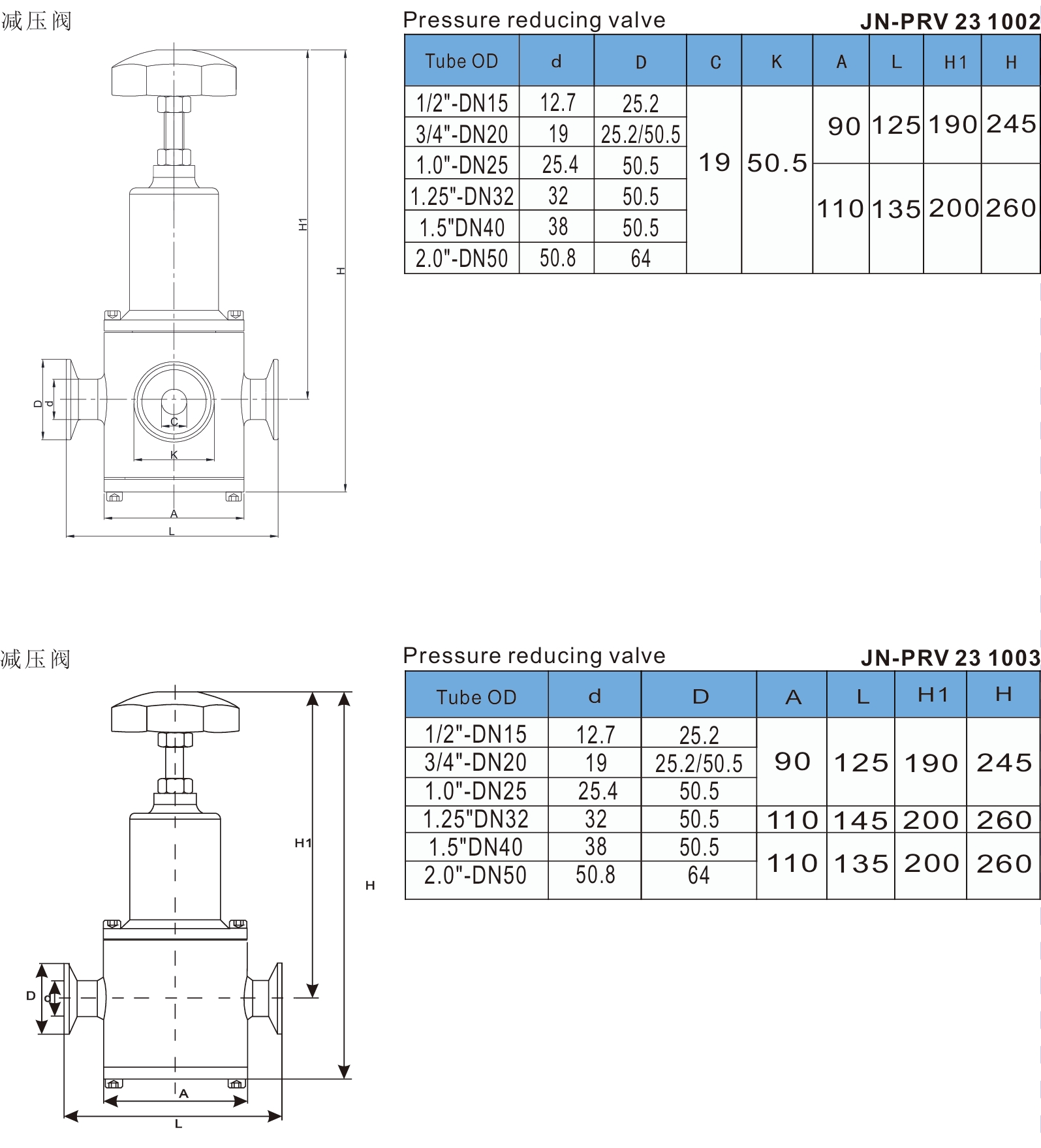

Specification Chart

Material | AISI304, AISI316L |

Size | 1" to 2" |

Seals | PTFE, EPDM, Viton |

End connections | Sanitary clamp |

Maximum pressure | 0 to 10 bar |

Maximum temperature | -15 °C to 148 °C |

Features

● The stainless steel sanitary pressure reducing valve has a built-in micro-filter that can effectively intercept impurities in the fluid and prevent them from entering the valve body and pipeline system.

● The stainless steel sanitary pressure reducing valve has an automatic compensation function, which can adjust the pressure setting value in real time to cope with flow fluctuations or changes in the external environment.

● The stainless steel sanitary pressure reducing valve adopts a double sealing structure, and the inner and outer sealing rings play different protective roles respectively, enhancing the sealing performance of the valve.

● The stainless steel sanitary pressure reducing valve integrates intelligent sensors and control systems, supports remote monitoring of valve status and remote adjustment.

● The stainless steel sanitary pressure reducing valve can adjust the output pressure very accurately through the fine-tuning spiral adjustment device to ensure stability.

● The stainless steel sanitary pressure reducing valve adopts a specially designed flow channel and shock absorbing device to significantly reduce the noise of the valve under low flow conditions.

Application

Stainless steel sanitary pressure reducing valves are widely used in the following industries: Food industry: ensure fluid stability, prevent pollution, and meet hygiene requirements. Pharmaceutical industry: accurately control pressure, ensure a sterile environment, and ensure product quality. Bioengineering: stabilize pressure and adapt to high cleanliness and special process requirements. Chemical industry: prevent high pressure from causing pipeline rupture, ensure safety and stability. Beverage industry: control fluid pressure to prevent affecting beverage quality and production process. Dairy industry: stabilize pipeline pressure, ensure fluid safety, and do not affect product quality. Medical industry: Ensure stable pipeline pressure to avoid contamination or equipment damage.