| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary circular normal pressure manhole is a circular opening device designed for high cleanliness environments, usually used for inspection, cleaning and maintenance of closed containers. The stainless steel sanitary circular normal pressure manhole is usually installed on the top or side wall of storage tanks, fermentation tanks, mixing tanks and cleaning tanks in the food, pharmaceutical, brewing, dairy and chemical industries. The top installation is mainly used for personnel to inspect, maintain and clean the inside of the tank, while the side wall installation is convenient for quick discharge of residues or observation of the tank. Common types of stainless steel sanitary circular normal pressure manholes include: top mounted manhole, side wall mounted manhole, manhole with sight glass, manhole with pressure balance valve, quick opening manhole, and seal enhanced manhole.

JONENG

8421219990

Stainless Steel Sanitary Silicone Round Normal Pressure Manhole

The stainless steel sanitary circular normal pressure manhole is designed to meet the special needs of high cleanliness and aseptic environments, especially for those cutting-edge fields with zero tolerance for contamination. Its core purpose is to ensure that there is no residue inside the equipment through a dead angle-free structure, precision welding and polished surface to avoid microbial growth or cross contamination. In addition, the quick opening design and sanitary sealing materials enable it to maintain efficient sealing during frequent opening and closing, reducing downtime. This design not only supports routine inspection and cleaning, but is also particularly suitable for scenes with extremely high cleanliness requirements such as cell culture, genetic engineering, and nanomaterial preparation, ensuring the purity and reliability of the process, while reducing maintenance costs and improving production efficiency.

Working Principles

The working principle of the stainless steel sanitary circular normal pressure manhole is based on mechanical locking and sealing technology to ensure the airtightness of the tank body and provide a convenient opening method. Under normal conditions, the manhole cover is fixed to the tank body by hinges, and the locking device applies uniform pressure to make the sealing ring fit tightly with the tank body to prevent external contaminants from entering or internal materials from leaking. When opening, the operator loosens the locking device, rotates or lifts the manhole cover to separate it from the sealing ring, and then uses the hinge to support the opening of the manhole cover to provide sufficient operating space. When closing, the manhole cover is reset along the hinge to ensure that the sealing ring is fully in contact with the tank flange, and then pressure is applied through the locking device to form a reliable seal.

The options for stainless steel sanitary circular normal pressure manholes include:

Material: 304, 316L, suitable for different corrosive environments

Sealing ring material: silicone, EPDM, PTFE, FKM, suitable for different media

Manhole cover thickness: different thicknesses can be selected to enhance strength or reduce weight

Surface treatment: polishing level can be selected mirror polishing, brushed, electrolytic polishing

Connection method: flange connection, welding connection, bolt fixing, etc.

Manhole cover shape: flat cover, convex cover, low plane design, to meet different applications

Locking method: handwheel locking, quick-open buckle, bolt tightening, suitable for different working conditions

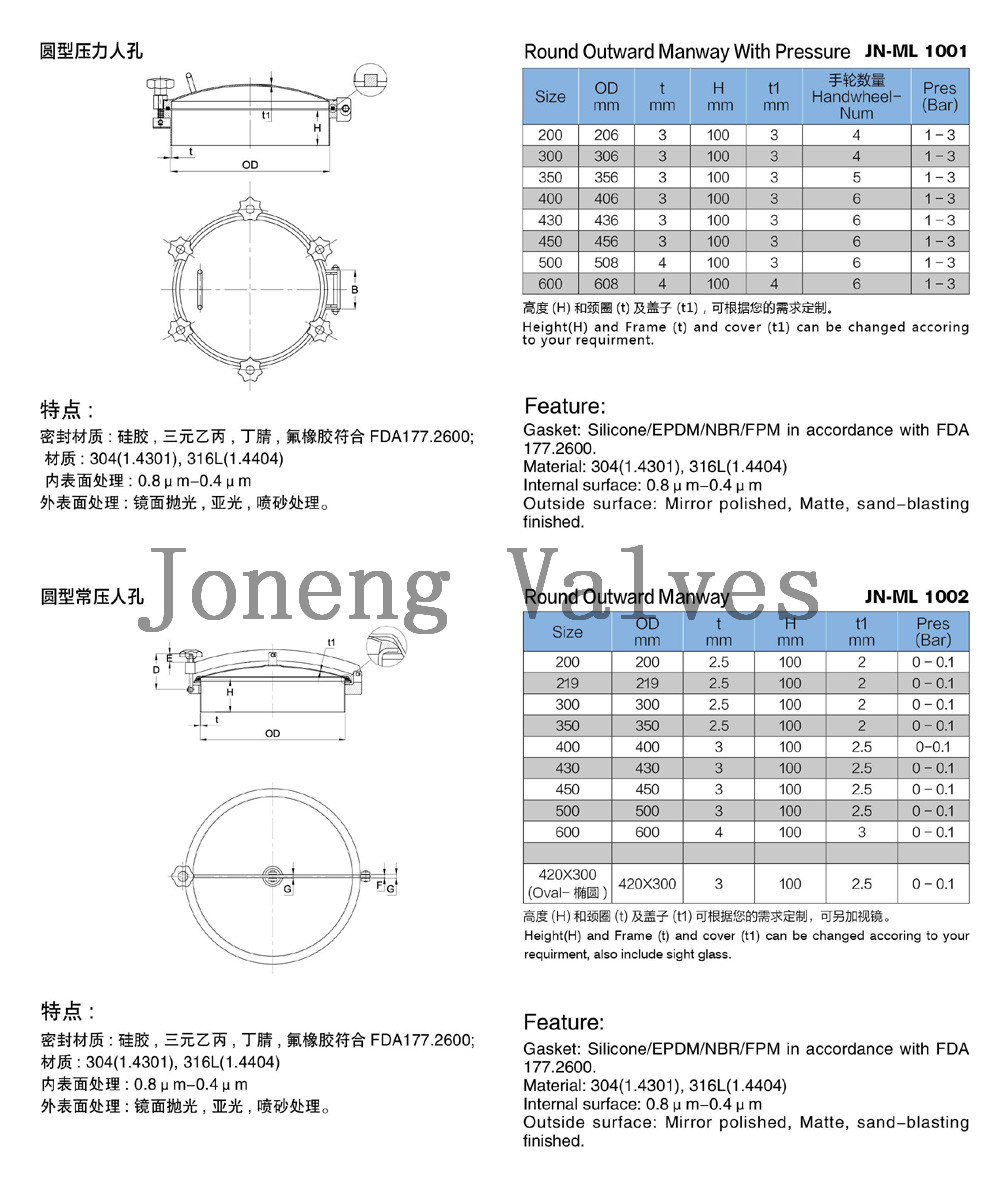

Specification Chart

Size | 200 to 600 mm |

Material | AISI304, AISI316L |

Seal | EPDM, PTFE, silicon |

Height | 100,120,150mm |

Maximum pressure | 10 bar |

Temperature range | -10 °C ~ 120 °C |

Features

● The stainless steel sanitary circular normal pressure manhole adopts a self-sealing design, without the need for additional sealing rings. The contact surface between the valve cover and the valve seat is precisely machined so that it automatically forms a seal when closed.

● The stainless steel sanitary circular normal pressure manhole adopts an optimized pressure bearing structure, which enhances the manhole's pressure resistance and can adapt to different environmental requirements such as high pressure and normal pressure.

● The stainless steel sanitary circular normal pressure manhole adopts a circular design without dead ends, which reduces the area of fluid retention and ensures smooth flow of fluid in any state.

● The connection part of the stainless steel sanitary circular normal pressure manhole adopts integrated welding technology, avoiding the use of threaded or flange interfaces and reducing the risk of contamination at the connection part.

● The inner and outer surfaces of the stainless steel sanitary circular normal pressure manhole are treated with a special coating to enhance corrosion resistance and reduce the adhesion of pollutants.

● The specially designed anti-leakage system of the stainless steel sanitary circular normal pressure manhole can prevent liquid and gas leakage under extreme conditions and ensure the closed state of the system.

Application

Stainless steel sanitary circular normal pressure manholes are widely used in the following industries: Food industry: used for cleaning, inspection and maintenance operations of storage tanks and reaction tanks. Pharmaceutical industry: meets GMP standards and is used for the inspection and cleaning of pharmaceutical production equipment. Bioengineering: Applicable to the high cleanliness requirements of fermentation tanks and bioreactors. Cosmetics industry: Applicable to the regular cleaning and maintenance of raw material storage tanks. Winemaking industry: Applicable to the inspection, cleaning and process monitoring of wine fermentation tanks. Chemical industry: Applicable to the inspection and maintenance of sanitary storage tanks and pipelines.

Working Principles

The working principle of the stainless steel sanitary circular normal pressure manhole is based on mechanical locking and sealing technology to ensure the airtightness of the tank body and provide a convenient opening method. Under normal conditions, the manhole cover is fixed to the tank body by hinges, and the locking device applies uniform pressure to make the sealing ring fit tightly with the tank body to prevent external contaminants from entering or internal materials from leaking. When opening, the operator loosens the locking device, rotates or lifts the manhole cover to separate it from the sealing ring, and then uses the hinge to support the opening of the manhole cover to provide sufficient operating space. When closing, the manhole cover is reset along the hinge to ensure that the sealing ring is fully in contact with the tank flange, and then pressure is applied through the locking device to form a reliable seal.

The options for stainless steel sanitary circular normal pressure manholes include:

Material: 304, 316L, suitable for different corrosive environments

Sealing ring material: silicone, EPDM, PTFE, FKM, suitable for different media

Manhole cover thickness: different thicknesses can be selected to enhance strength or reduce weight

Surface treatment: polishing level can be selected mirror polishing, brushed, electrolytic polishing

Connection method: flange connection, welding connection, bolt fixing, etc.

Manhole cover shape: flat cover, convex cover, low plane design, to meet different applications

Locking method: handwheel locking, quick-open buckle, bolt tightening, suitable for different working conditions

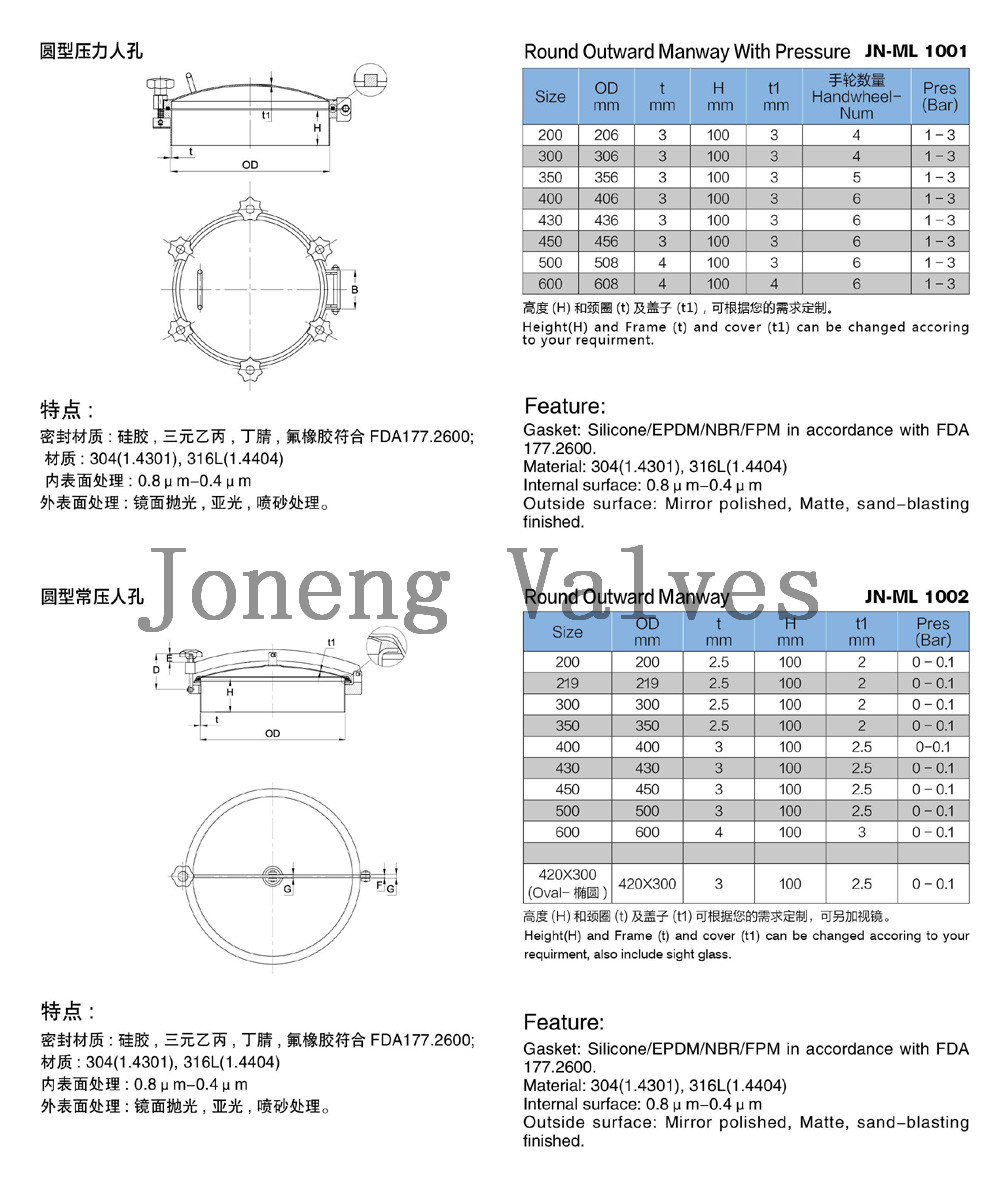

Specification Chart

Size | 200 to 600 mm |

Material | AISI304, AISI316L |

Seal | EPDM, PTFE, silicon |

Height | 100,120,150mm |

Maximum pressure | 10 bar |

Temperature range | -10 °C ~ 120 °C |

Features

● The stainless steel sanitary circular normal pressure manhole adopts a self-sealing design, without the need for additional sealing rings. The contact surface between the valve cover and the valve seat is precisely machined so that it automatically forms a seal when closed.

● The stainless steel sanitary circular normal pressure manhole adopts an optimized pressure bearing structure, which enhances the manhole's pressure resistance and can adapt to different environmental requirements such as high pressure and normal pressure.

● The stainless steel sanitary circular normal pressure manhole adopts a circular design without dead ends, which reduces the area of fluid retention and ensures smooth flow of fluid in any state.

● The connection part of the stainless steel sanitary circular normal pressure manhole adopts integrated welding technology, avoiding the use of threaded or flange interfaces and reducing the risk of contamination at the connection part.

● The inner and outer surfaces of the stainless steel sanitary circular normal pressure manhole are treated with a special coating to enhance corrosion resistance and reduce the adhesion of pollutants.

● The specially designed anti-leakage system of the stainless steel sanitary circular normal pressure manhole can prevent liquid and gas leakage under extreme conditions and ensure the closed state of the system.

Application

Stainless steel sanitary circular normal pressure manholes are widely used in the following industries: Food industry: used for cleaning, inspection and maintenance operations of storage tanks and reaction tanks. Pharmaceutical industry: meets GMP standards and is used for the inspection and cleaning of pharmaceutical production equipment. Bioengineering: Applicable to the high cleanliness requirements of fermentation tanks and bioreactors. Cosmetics industry: Applicable to the regular cleaning and maintenance of raw material storage tanks. Winemaking industry: Applicable to the inspection, cleaning and process monitoring of wine fermentation tanks. Chemical industry: Applicable to the inspection and maintenance of sanitary storage tanks and pipelines.