| Availability: | |

|---|---|

| Quantity: | |

JN 1025

JONENG

8481804090

Stainless Steel Sanitary Sterile Flow Diversion Pneumatic Stop Valve

The core of the design of the stainless steel sanitary aseptic pneumatic stop valve is to achieve precise fluid control in a sterile environment while minimizing the risk of cross contamination. Its internal flow channel has been optimized to ensure that there is no stagnation and dead angle in the fluid channel, so that it can quickly empty the residue and avoid microbial growth in the production process with high cleanliness requirements. This valve is particularly suitable for production lines that require high-frequency opening and closing. It can achieve rapid response through pneumatic drive, improve the control accuracy of process fluids, and reduce errors caused by manual operation. Its special sealing structure can maintain long-term stable operation in high temperature, high pressure, and highly corrosive media environments, and is widely used in pharmaceutical, bioengineering, food and beverage and other industries.

Working Principles

The working principle of the stainless steel sanitary aseptic pneumatic stop valve is based on the pneumatic drive mechanism to control the opening and closing of the valve core to achieve precise control of the fluid. During operation, compressed air enters the actuator through the solenoid valve, pushes the piston or diaphragm, moves the valve stem downward, presses the valve core, and thus closes the valve and cuts off the fluid. When the valve needs to be opened, the control system releases the air pressure. Under the action of spring reset or reverse air pressure, the valve stem moves up, and the valve core leaves the valve seat, allowing the fluid to pass smoothly. In order to ensure a sterile environment, the valve adopts a smooth and dead-angle-free flow channel design inside the valve to ensure that the fluid will not be retained when passing through, and supports online cleaning (CIP) and online sterilization (SIP). Some models are equipped with an intelligent control unit that can monitor the valve status in real time, realize automatic adjustment and feedback, and improve the accuracy and stability of production.

The options for stainless steel sanitary aseptic pneumatic stop valves include:

Valve body structure: straight-through, angle seat, double seat, diaphragm

Drive mode: single-acting (normally open/normally closed), double-acting

Seal material: EPDM, PTFE, FKM (fluororubber), Silicone

Control mode: manual emergency function, solenoid valve control, intelligent control unit (with feedback)

Surface treatment: polishing (Ra≤0.4μm), electrolytic polishing

Connection mode: quick-install (quick-install), welding, thread, flange

Valve body material: 304, 316L

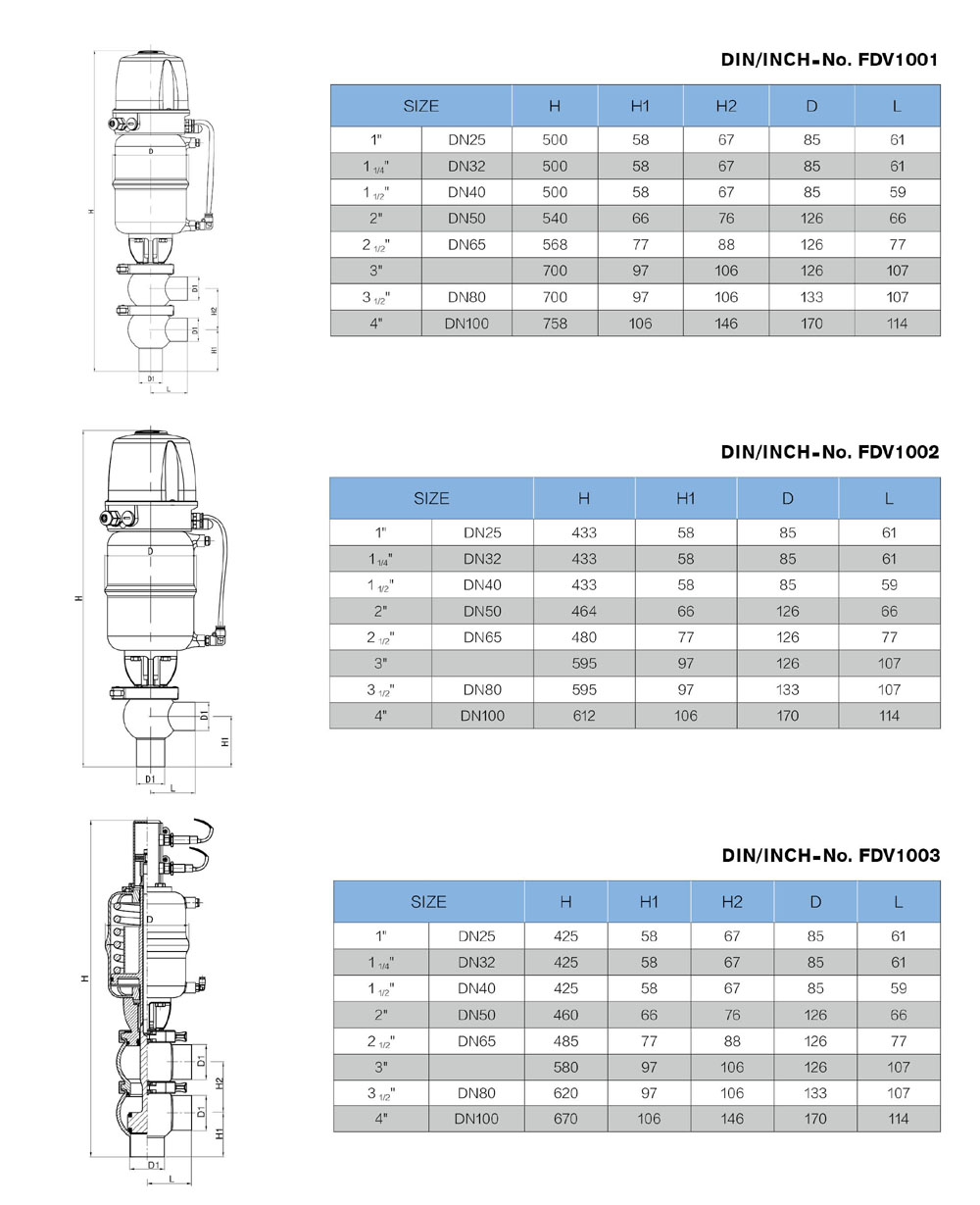

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary aseptic pneumatic stop valve adopts the intelligent adjustment system of the pneumatic actuator, which automatically adjusts the opening force according to the fluid pressure, reduces the gas source consumption and improves energy efficiency.

● The stainless steel sanitary aseptic pneumatic stop valve reduces the vacuum bubbles formed by high-speed fluid inside the valve by optimizing the curvature and flow area of the fluid channel.

● The stainless steel sanitary aseptic pneumatic stop valve adopts reinforced spring components and low-friction sealing materials, so that the valve can complete high-frequency switching operations in a short time.

● The stainless steel sanitary aseptic pneumatic stop valve adds a pressure relief cavity in the valve core structure, so that the valve can evenly disperse the pressure at the moment of closing to avoid water hammer impact.

● The bottom of the stainless steel sanitary aseptic pneumatic stop valve body adopts a specific inclination design, which can completely drain the fluid during shutdown or cleaning, prevent residue retention, and reduce the risk of microbial growth.

● The stainless steel sanitary aseptic pneumatic stop valve adopts self-lubricating and wear-resistant sealing materials, so that the seals can maintain a low wear state during long-term operation and reduce the risk of leakage caused by seal aging.

Application

Stainless steel sanitary aseptic pneumatic stop valves are widely used in the following industries: Pharmaceutical industry: used for aseptic drug production, transportation and isolation to ensure that the drugs are contaminated. Bioengineering: processing culture media and biological preparations to meet aseptic environment requirements. Food industry: high-cleanliness food processing and filling to prevent cross contamination. Beverage industry: aseptic beverage production and packaging to ensure product hygiene and safety. Cosmetics industry: high-purity raw material transportation and isolation to ensure product quality. Dairy industry: aseptic processing of milk and yogurt to extend shelf life. Winemaking industry: aseptic filling of wine and liquor to maintain pure flavor.

Working Principles

The working principle of the stainless steel sanitary aseptic pneumatic stop valve is based on the pneumatic drive mechanism to control the opening and closing of the valve core to achieve precise control of the fluid. During operation, compressed air enters the actuator through the solenoid valve, pushes the piston or diaphragm, moves the valve stem downward, presses the valve core, and thus closes the valve and cuts off the fluid. When the valve needs to be opened, the control system releases the air pressure. Under the action of spring reset or reverse air pressure, the valve stem moves up, and the valve core leaves the valve seat, allowing the fluid to pass smoothly. In order to ensure a sterile environment, the valve adopts a smooth and dead-angle-free flow channel design inside the valve to ensure that the fluid will not be retained when passing through, and supports online cleaning (CIP) and online sterilization (SIP). Some models are equipped with an intelligent control unit that can monitor the valve status in real time, realize automatic adjustment and feedback, and improve the accuracy and stability of production.

The options for stainless steel sanitary aseptic pneumatic stop valves include:

Valve body structure: straight-through, angle seat, double seat, diaphragm

Drive mode: single-acting (normally open/normally closed), double-acting

Seal material: EPDM, PTFE, FKM (fluororubber), Silicone

Control mode: manual emergency function, solenoid valve control, intelligent control unit (with feedback)

Surface treatment: polishing (Ra≤0.4μm), electrolytic polishing

Connection mode: quick-install (quick-install), welding, thread, flange

Valve body material: 304, 316L

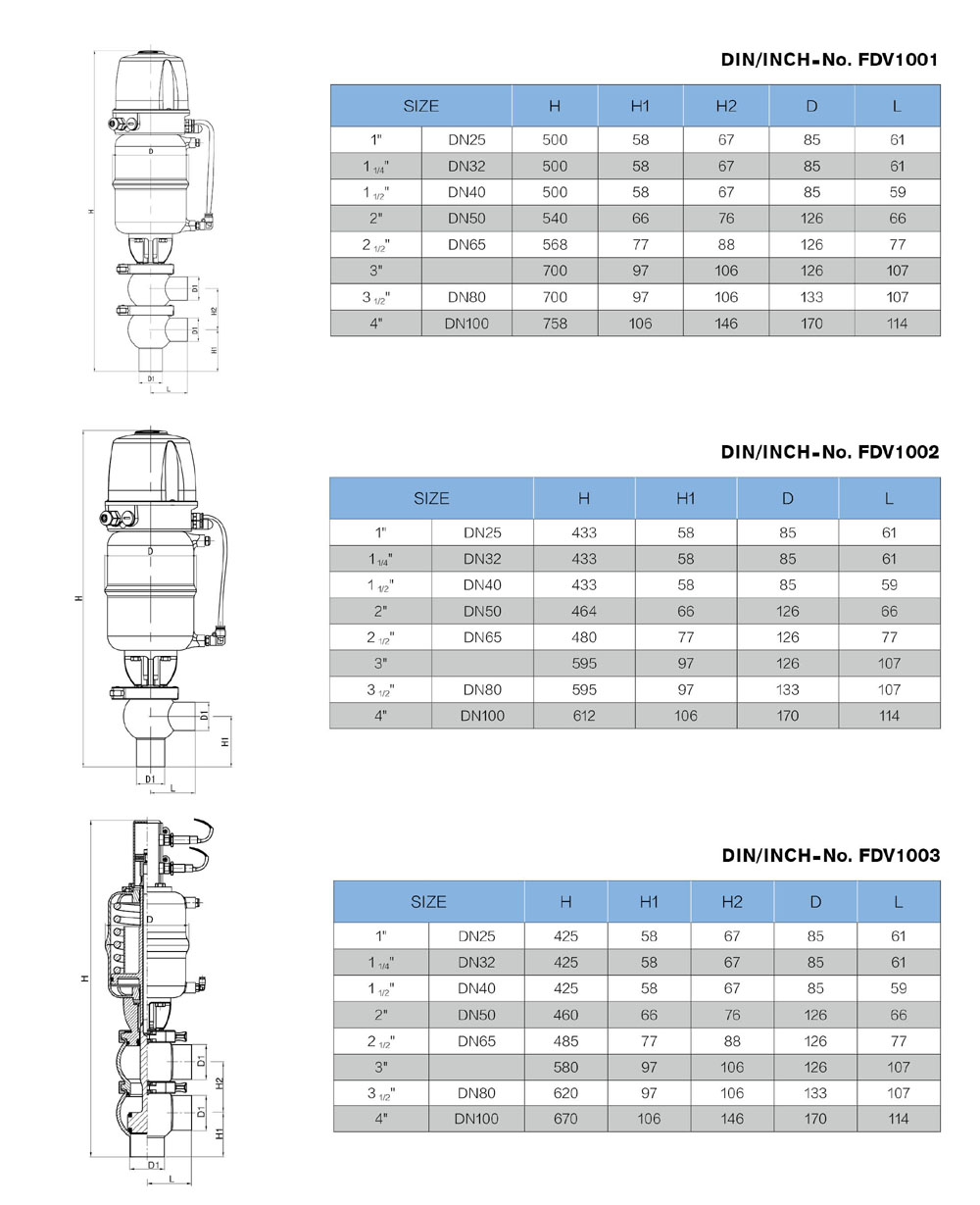

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary aseptic pneumatic stop valve adopts the intelligent adjustment system of the pneumatic actuator, which automatically adjusts the opening force according to the fluid pressure, reduces the gas source consumption and improves energy efficiency.

● The stainless steel sanitary aseptic pneumatic stop valve reduces the vacuum bubbles formed by high-speed fluid inside the valve by optimizing the curvature and flow area of the fluid channel.

● The stainless steel sanitary aseptic pneumatic stop valve adopts reinforced spring components and low-friction sealing materials, so that the valve can complete high-frequency switching operations in a short time.

● The stainless steel sanitary aseptic pneumatic stop valve adds a pressure relief cavity in the valve core structure, so that the valve can evenly disperse the pressure at the moment of closing to avoid water hammer impact.

● The bottom of the stainless steel sanitary aseptic pneumatic stop valve body adopts a specific inclination design, which can completely drain the fluid during shutdown or cleaning, prevent residue retention, and reduce the risk of microbial growth.

● The stainless steel sanitary aseptic pneumatic stop valve adopts self-lubricating and wear-resistant sealing materials, so that the seals can maintain a low wear state during long-term operation and reduce the risk of leakage caused by seal aging.

Application

Stainless steel sanitary aseptic pneumatic stop valves are widely used in the following industries: Pharmaceutical industry: used for aseptic drug production, transportation and isolation to ensure that the drugs are contaminated. Bioengineering: processing culture media and biological preparations to meet aseptic environment requirements. Food industry: high-cleanliness food processing and filling to prevent cross contamination. Beverage industry: aseptic beverage production and packaging to ensure product hygiene and safety. Cosmetics industry: high-purity raw material transportation and isolation to ensure product quality. Dairy industry: aseptic processing of milk and yogurt to extend shelf life. Winemaking industry: aseptic filling of wine and liquor to maintain pure flavor.