| Availability: | |

|---|---|

| Quantity: | |

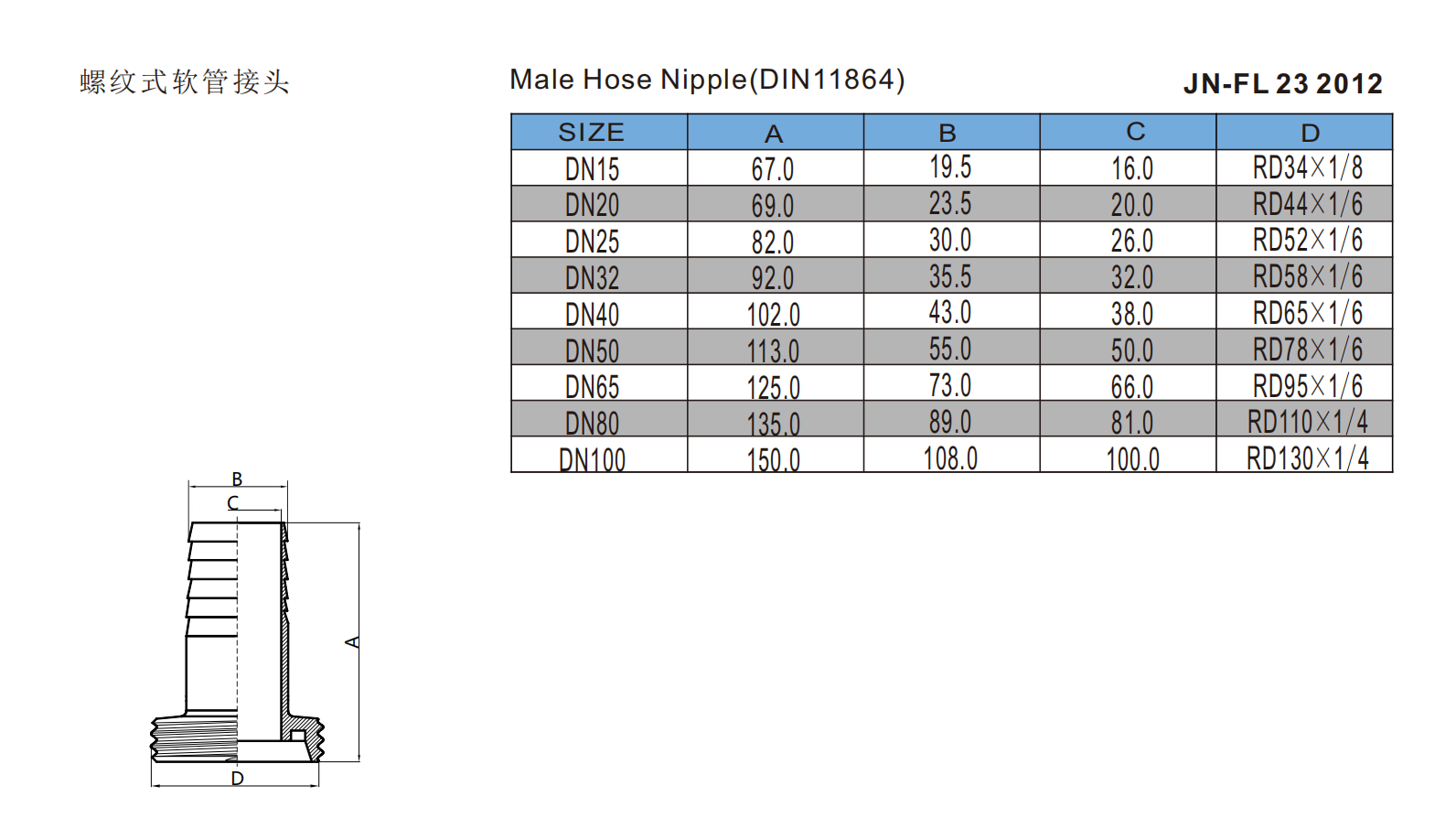

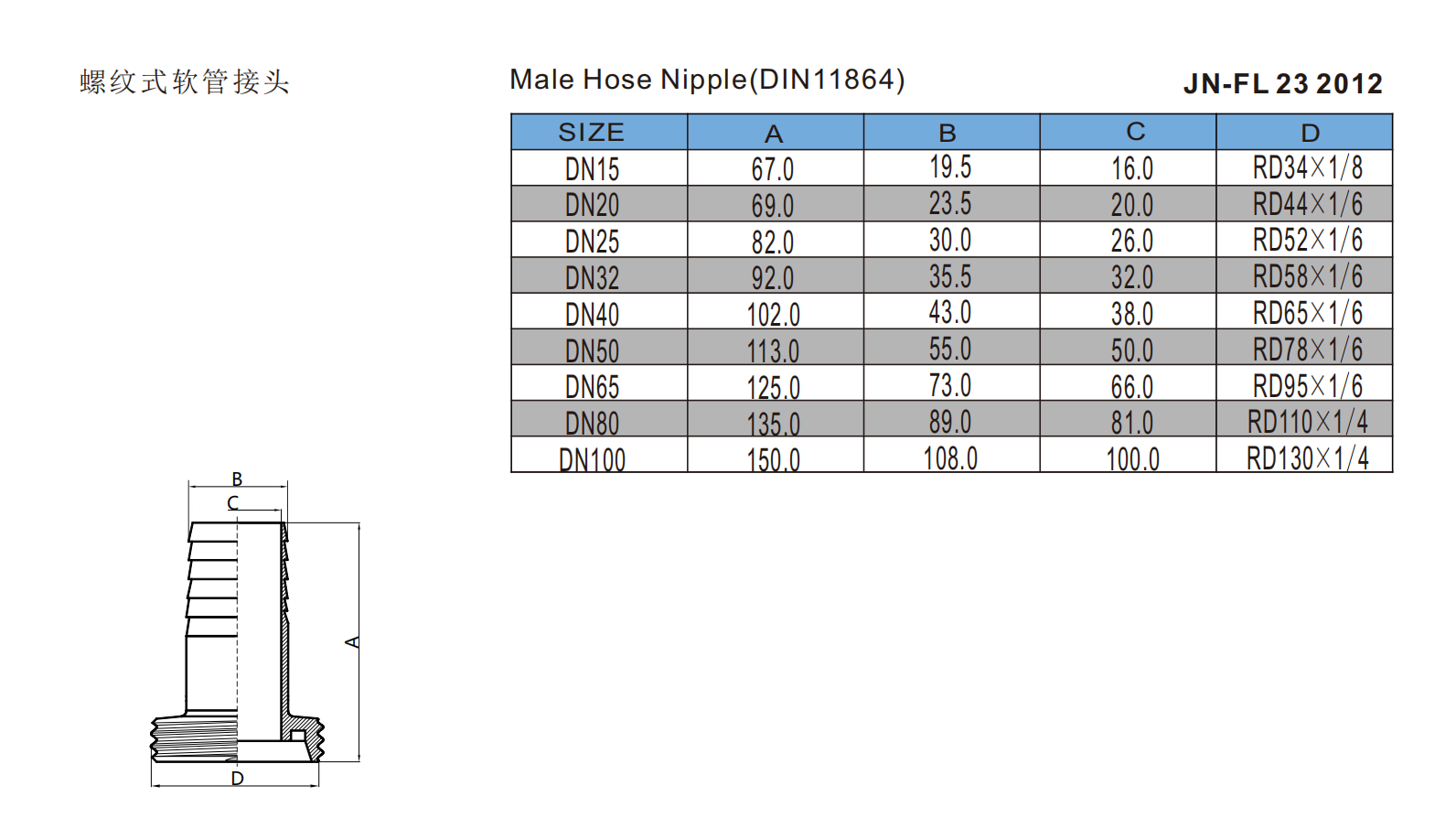

JN-FL 23 2012

JONENG

7307290000

Stainless Steel Sanitary Thread Electrolytic Polishing Hose Nipple Connector

The design purpose of stainless steel sanitary threaded hose connector is to provide a flexible, efficient and safe connection method in the pipeline system. It connects hoses of different specifications or types to pipes, equipment, etc. through threaded connection to achieve transition or conversion between different pipes. This design can cope with the needs of frequent disassembly, cleaning and maintenance, and ensure the hygiene and sealing of the system. The use of adapters ensures the stability of the pipe connection, while avoiding leakage problems caused by size mismatch or irregular interfaces. It is especially suitable for industries with strict hygiene requirements, such as food, pharmaceuticals and chemicals.

Working principle

The working principle of stainless steel sanitary threaded hose connectors is to achieve sealing and conversion between pipes through threaded connection. Align the internal or external thread end of the hose connector with the corresponding thread end of the pipe or equipment, tighten it by rotating to make the threads bite, and connect the other end of the hose connector (such as quick-fit, clamp or flange interface) to another pipe or equipment, ensuring that the interface is aligned and fixed. Through the tight bite of the threads and the action of the sealing ring (if applicable), a sealing structure is formed to prevent medium leakage, thereby achieving a safe and reliable connection between pipes of different specifications or types.

The options for stainless steel sanitary threaded hose connectors include:

Material: 304 or 316L stainless steel, corrosion-resistant.

Interface type: internal thread, external thread, quick-fit, clamp, flange, etc.

Size: multiple specifications, suitable for different pipe sizes.

Sealing method: sealing ring, gasket or no seal design.

Surface treatment: polishing, electrolytic polishing, to improve the sanitation level.

Special design: elbow, tee, etc., to meet complex connection requirements.

Specification Chart

| Material | SS304, SS316L | |

| Diameter | 1 "to 24" | |

| Length | 95mm to 265mm | |

| Standard | DIN, ISO, ASTM | |

| Max pressure | up to 10 bar | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Working temperatur | -15℃ to +160℃ | |

| End connections | Flanged, Threaded | |

| Gasket or seals | Viton, PTFEE | |

Features

● The stainless steel sanitary threaded hose connector adopts a high-precision thread cutting process to ensure that the thread and the pipe or equipment connector are perfectly matched to avoid leakage caused by misalignment of the thread.

● The design of the stainless steel sanitary threaded hose connector can achieve seamless connection between pipes of different specifications and types, meeting the adaptation requirements from internal threads to external threads or pipes of different sizes.

● The special material and structural design of the stainless steel sanitary threaded hose connector can withstand long-term use in high temperature environments and prevent the hose connector from loosening due to thermal expansion or thermal deformation.

● The stainless steel sanitary threaded hose connector adopts a quick loading and unloading design, which is convenient for operators to quickly connect or remove the hose when needed, reducing operation time.

● The stainless steel sanitary threaded hose connector adopts specially treated stainless steel material, which has strong chemical corrosion resistance and is suitable for the flow of various acidic and alkaline media.

● The inner and outer surfaces of the stainless steel sanitary threaded hose connector are treated with low friction to reduce the resistance and wear of the fluid when passing through, ensuring the smooth flow of the fluid.

Application

Stainless steel sanitary threaded hose connectors are widely used in the following industries: Food industry: ensure hygiene and sealing during food fluid transportation. Pharmaceutical industry: ensure the sterility and stability of the pipeline system during drug production. Beverage industry: ensure contamination-free fluid transportation in beverage production lines. Chemical industry: suitable for stable transportation of chemical substances and corrosion resistance. Dairy industry: ensure the purity and safety of fluids in dairy production. Biopharmaceutical industry: ensure high-precision fluid transportation to avoid cross contamination. Cosmetics industry: Suitable for high requirements on fluid hygiene in the cosmetics production process.

Working principle

The working principle of stainless steel sanitary threaded hose connectors is to achieve sealing and conversion between pipes through threaded connection. Align the internal or external thread end of the hose connector with the corresponding thread end of the pipe or equipment, tighten it by rotating to make the threads bite, and connect the other end of the hose connector (such as quick-fit, clamp or flange interface) to another pipe or equipment, ensuring that the interface is aligned and fixed. Through the tight bite of the threads and the action of the sealing ring (if applicable), a sealing structure is formed to prevent medium leakage, thereby achieving a safe and reliable connection between pipes of different specifications or types.

The options for stainless steel sanitary threaded hose connectors include:

Material: 304 or 316L stainless steel, corrosion-resistant.

Interface type: internal thread, external thread, quick-fit, clamp, flange, etc.

Size: multiple specifications, suitable for different pipe sizes.

Sealing method: sealing ring, gasket or no seal design.

Surface treatment: polishing, electrolytic polishing, to improve the sanitation level.

Special design: elbow, tee, etc., to meet complex connection requirements.

Specification Chart

| Material | SS304, SS316L | |

| Diameter | 1 "to 24" | |

| Length | 95mm to 265mm | |

| Standard | DIN, ISO, ASTM | |

| Max pressure | up to 10 bar | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Working temperatur | -15℃ to +160℃ | |

| End connections | Flanged, Threaded | |

| Gasket or seals | Viton, PTFEE | |

Features

● The stainless steel sanitary threaded hose connector adopts a high-precision thread cutting process to ensure that the thread and the pipe or equipment connector are perfectly matched to avoid leakage caused by misalignment of the thread.

● The design of the stainless steel sanitary threaded hose connector can achieve seamless connection between pipes of different specifications and types, meeting the adaptation requirements from internal threads to external threads or pipes of different sizes.

● The special material and structural design of the stainless steel sanitary threaded hose connector can withstand long-term use in high temperature environments and prevent the hose connector from loosening due to thermal expansion or thermal deformation.

● The stainless steel sanitary threaded hose connector adopts a quick loading and unloading design, which is convenient for operators to quickly connect or remove the hose when needed, reducing operation time.

● The stainless steel sanitary threaded hose connector adopts specially treated stainless steel material, which has strong chemical corrosion resistance and is suitable for the flow of various acidic and alkaline media.

● The inner and outer surfaces of the stainless steel sanitary threaded hose connector are treated with low friction to reduce the resistance and wear of the fluid when passing through, ensuring the smooth flow of the fluid.

Application

Stainless steel sanitary threaded hose connectors are widely used in the following industries: Food industry: ensure hygiene and sealing during food fluid transportation. Pharmaceutical industry: ensure the sterility and stability of the pipeline system during drug production. Beverage industry: ensure contamination-free fluid transportation in beverage production lines. Chemical industry: suitable for stable transportation of chemical substances and corrosion resistance. Dairy industry: ensure the purity and safety of fluids in dairy production. Biopharmaceutical industry: ensure high-precision fluid transportation to avoid cross contamination. Cosmetics industry: Suitable for high requirements on fluid hygiene in the cosmetics production process.