| Availability: | |

|---|---|

| Quantity: | |

JN-DPHV-23 1010-BJ

JONENG

8481804090

Stainless Steel Sanitary U Type In-line Diaphragm Valves

The stainless steel sanitary manually welded U-shaped diaphragm valve is designed for high-purity applications in food, pharma, and dairy industries. Its straight-through design ensures smooth, retention-free flow, while welded connections enhance sealing. The manual operation allows easy on-site control, and the diaphragm isolates the actuator from the media, supporting sterile conditions and CIP/SIP cleaning.

Working Principles

This valve operates by manually raising or lowering the diaphragm via a handwheel. Pressing the diaphragm seals the valve; lifting it allows fluid to flow through the U-shaped straight-through path. The diaphragm fully isolates the medium from the actuator, ensuring sterility and supporting CIP/SIP cleaning.

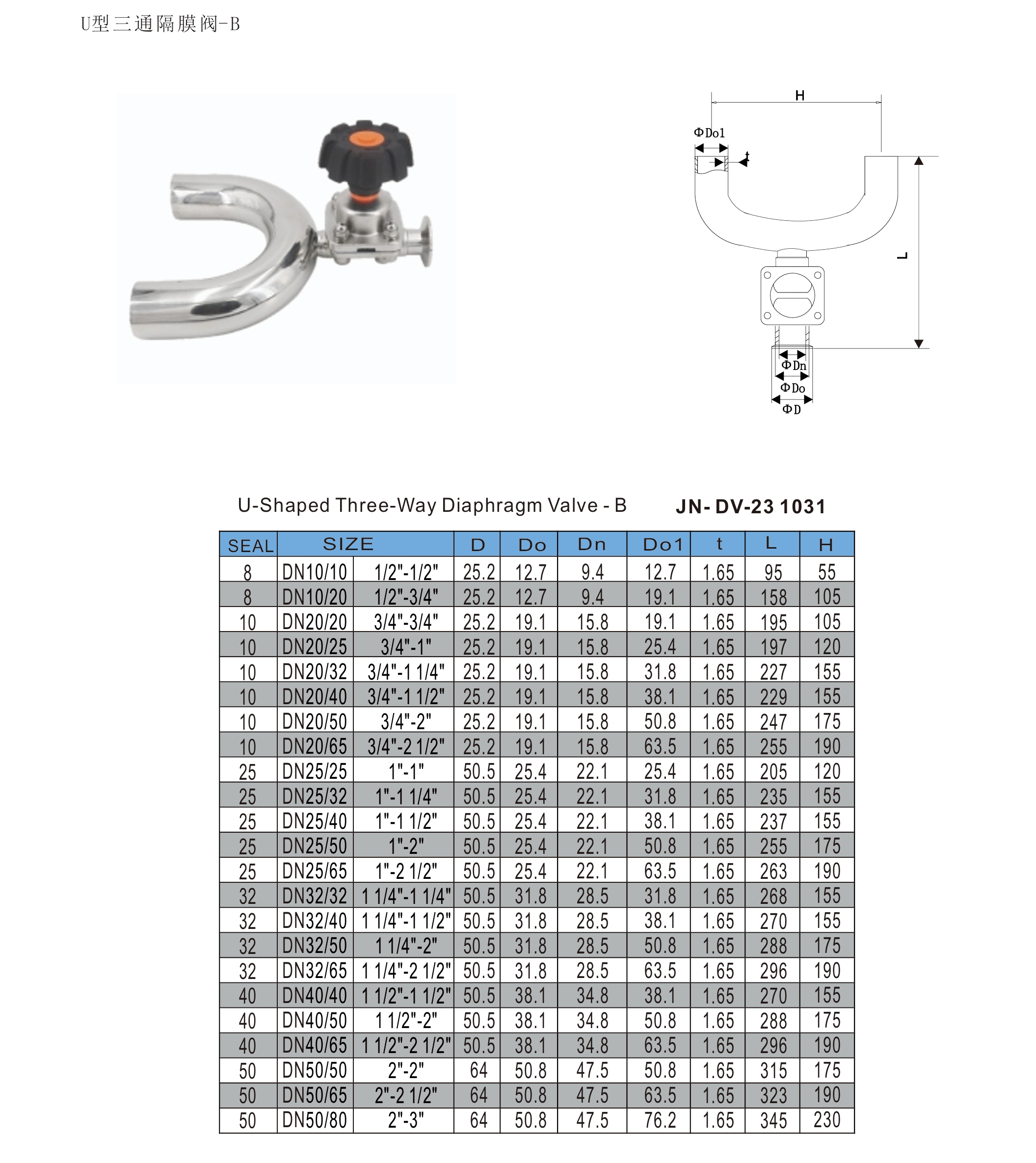

Stainless Steel Diaphragm Valve Specification Chart

Valve Type | Manual Welded U-Type Diaphragm Valve |

Connection Type | Welded Ends |

Nominal Sizes | DN10-DN100/1/2-4” |

Working Pressure | 0-10 bar |

Operating Temperature | -10°C to to 150°C |

Flow Pattern | Straight-through (U-Type) |

Body Surface Finish | Ra ≤ 0.6 μm (inner), Ra ≤ 1.2 μm (outer) |

Cleaning Compatibility | CIP/SIP |

Diaphragm Materials | EPDM, EPDM+PTFE, FPM |

Body Materials | AISI 316L/AISI 304 |

| Handwheel Material | Stainless Steel / Plastic / Aluminum Alloy |

| Mounting Orientation | Horizontal or Vertical |

Features

● Smooth flow path with no dead spots, preventing media stagnation and meeting high-cleanliness process requirements.

● Strong sealing at joints prevents leaks and bacterial growth.

● The diaphragm is adjusted by handwheel to open or close the flow.

● The diaphragm completely isolates the media from the drive mechanism, ensuring a sterile environment.

● Suitable for CIP/SIP cleaning, meeting food and pharmaceutical industry standards.

● Made of 316L stainless steel, it is adaptable to a variety of media and operating conditions.

Application

Stainless steel sanitary U-shaped diaphragm valves are used in food, pharma, dairy, and beverage industries. In dairy processing, they control milk flow, ensure sterile pipelines, and prevent contamination to meet hygiene standards.

Working Principles

This valve operates by manually raising or lowering the diaphragm via a handwheel. Pressing the diaphragm seals the valve; lifting it allows fluid to flow through the U-shaped straight-through path. The diaphragm fully isolates the medium from the actuator, ensuring sterility and supporting CIP/SIP cleaning.

Stainless Steel Diaphragm Valve Specification Chart

Valve Type | Manual Welded U-Type Diaphragm Valve |

Connection Type | Welded Ends |

Nominal Sizes | DN10-DN100/1/2-4” |

Working Pressure | 0-10 bar |

Operating Temperature | -10°C to to 150°C |

Flow Pattern | Straight-through (U-Type) |

Body Surface Finish | Ra ≤ 0.6 μm (inner), Ra ≤ 1.2 μm (outer) |

Cleaning Compatibility | CIP/SIP |

Diaphragm Materials | EPDM, EPDM+PTFE, FPM |

Body Materials | AISI 316L/AISI 304 |

| Handwheel Material | Stainless Steel / Plastic / Aluminum Alloy |

| Mounting Orientation | Horizontal or Vertical |

Features

● Smooth flow path with no dead spots, preventing media stagnation and meeting high-cleanliness process requirements.

● Strong sealing at joints prevents leaks and bacterial growth.

● The diaphragm is adjusted by handwheel to open or close the flow.

● The diaphragm completely isolates the media from the drive mechanism, ensuring a sterile environment.

● Suitable for CIP/SIP cleaning, meeting food and pharmaceutical industry standards.

● Made of 316L stainless steel, it is adaptable to a variety of media and operating conditions.

Application

Stainless steel sanitary U-shaped diaphragm valves are used in food, pharma, dairy, and beverage industries. In dairy processing, they control milk flow, ensure sterile pipelines, and prevent contamination to meet hygiene standards.