| Availability: | |

|---|---|

| Quantity: | |

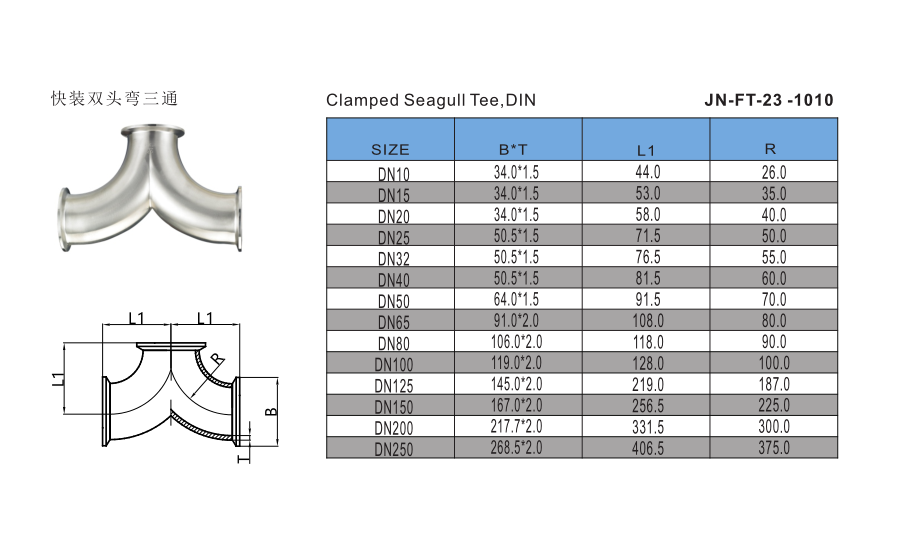

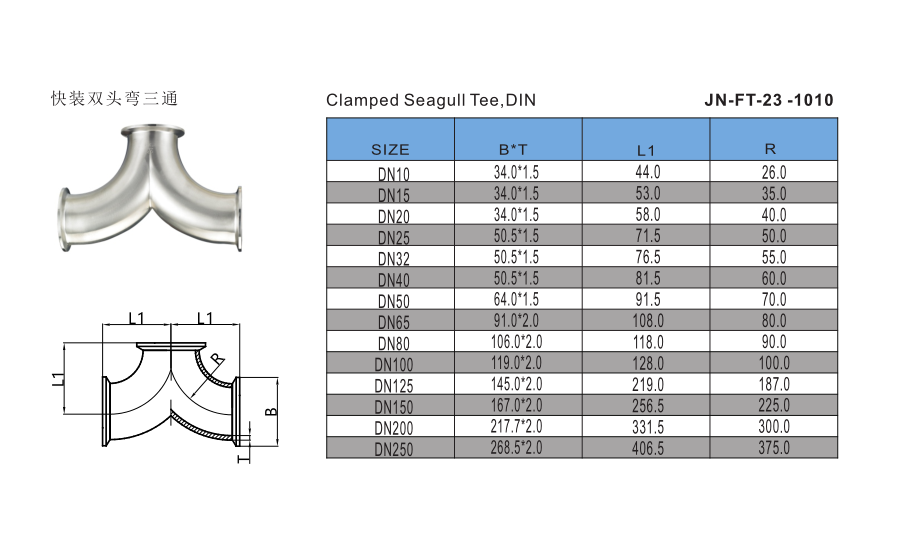

JN-FT-23 -1010

JONENG

7307290000

Stainless Steel Sanitary Y-type Bevel Polished Welding Tee

The stainless steel sanitary Y-type welded tee is designed to optimize the flow path of the fluid in the pipeline system and reduce the turbulence and pressure loss that may occur during the fluid flow. Through the Y-shaped fluid guide structure, this tee can achieve smoother and more stable fluid distribution or convergence, which is particularly suitable for systems that require high-precision flow control and high efficiency. In an environment with high sanitation standards, the tee connected by welding can effectively prevent leakage and fouling and maintain the purity of the fluid. In addition, its unique angle design helps to reduce the fluid resistance caused by turning or changing the flow direction, thereby improving the overall flow efficiency and stability of the pipeline system, and is widely used in the fine management and sanitation requirements of fluid flow in the food, pharmaceutical, chemical and other industries.

Working Principles

The working principle of the stainless steel sanitary Y-type welded tee is based on its unique Y-type structural design, which is designed to guide the fluid to smoothly divert or merge. When the fluid enters the main inlet of the tee, the fluid enters the two branch outlets or confluence ports through the Y-shaped channel of the pipeline, and the fluid direction changes. Due to the small fluid guide angle of the Y-type structure, the fluid is less affected by resistance or turbulence during the flow process, thereby reducing pressure loss and improving flow efficiency. When the fluid is diverted, the Y-type tee ensures that the flow between the various branch pipes is balanced, avoiding excessive fluid concentration in a certain branch. When converging, the convergence path of the fluid transitions smoothly.

The options for stainless steel sanitary Y-type welded tees include:

Connection method: welding, quick installation

Size: selected according to the pipe diameter

Angle design: right angle, bevel

Seal material: EPDM, PTFE

Surface treatment: polishing, sandblasting

Pressure level: customized according to system requirements

Special design: variable diameter, reinforced design

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The flow channel design of the stainless steel sanitary Y-type welded tee adopts a streamlined shape with a smooth inner wall and no dead angles, which can effectively reduce the turbulence phenomenon during the flow of the fluid and ensure a smooth transition of the fluid.

● The stainless steel sanitary Y-type welded tee reduces the flow resistance of the fluid through the precisely calculated angle and outlet design, especially when the flow rate or high-speed fluid is transmitted.

● The internal coating of the stainless steel sanitary Y-type welded tee adopts advanced anti-corrosion materials, which can maintain good performance even in a highly corrosive fluid environment.

● The stainless steel sanitary Y-type welded tee adopts precision welding technology to ensure the uniformity and strength of the welding points and avoid welding defects.

● The inner and outer surfaces of the stainless steel sanitary Y-type welded tee adopt advanced no-dead-angle polishing technology to reduce the accumulation of microorganisms and impurities.

● The stainless steel sanitary Y-type welded tee adopts seamless welding technology to avoid the risk of leakage caused by traditional connection methods and provide higher sealing.

Application

Stainless steel sanitary Y-type welded tees are widely used in the following industries: Food and beverage industry: used for diversion or mixing process pipelines to ensure no residue hygiene standards. Pharmaceutical industry: purified water, liquid medicine distribution system, meet GMP aseptic requirements. Bioengineering: cell culture, fermentation tank pipelines, avoid cross contamination risks. Dairy industry: Milk and ingredient delivery pipelines, corrosion-resistant and easy to clean and disinfect. Cosmetics industry: High-viscosity raw material delivery, ensuring chemical compatibility. Semiconductor industry: Ultrapure water and chemical distribution, in line with clean room cleanliness levels.

Working Principles

The working principle of the stainless steel sanitary Y-type welded tee is based on its unique Y-type structural design, which is designed to guide the fluid to smoothly divert or merge. When the fluid enters the main inlet of the tee, the fluid enters the two branch outlets or confluence ports through the Y-shaped channel of the pipeline, and the fluid direction changes. Due to the small fluid guide angle of the Y-type structure, the fluid is less affected by resistance or turbulence during the flow process, thereby reducing pressure loss and improving flow efficiency. When the fluid is diverted, the Y-type tee ensures that the flow between the various branch pipes is balanced, avoiding excessive fluid concentration in a certain branch. When converging, the convergence path of the fluid transitions smoothly.

The options for stainless steel sanitary Y-type welded tees include:

Connection method: welding, quick installation

Size: selected according to the pipe diameter

Angle design: right angle, bevel

Seal material: EPDM, PTFE

Surface treatment: polishing, sandblasting

Pressure level: customized according to system requirements

Special design: variable diameter, reinforced design

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The flow channel design of the stainless steel sanitary Y-type welded tee adopts a streamlined shape with a smooth inner wall and no dead angles, which can effectively reduce the turbulence phenomenon during the flow of the fluid and ensure a smooth transition of the fluid.

● The stainless steel sanitary Y-type welded tee reduces the flow resistance of the fluid through the precisely calculated angle and outlet design, especially when the flow rate or high-speed fluid is transmitted.

● The internal coating of the stainless steel sanitary Y-type welded tee adopts advanced anti-corrosion materials, which can maintain good performance even in a highly corrosive fluid environment.

● The stainless steel sanitary Y-type welded tee adopts precision welding technology to ensure the uniformity and strength of the welding points and avoid welding defects.

● The inner and outer surfaces of the stainless steel sanitary Y-type welded tee adopt advanced no-dead-angle polishing technology to reduce the accumulation of microorganisms and impurities.

● The stainless steel sanitary Y-type welded tee adopts seamless welding technology to avoid the risk of leakage caused by traditional connection methods and provide higher sealing.

Application

Stainless steel sanitary Y-type welded tees are widely used in the following industries: Food and beverage industry: used for diversion or mixing process pipelines to ensure no residue hygiene standards. Pharmaceutical industry: purified water, liquid medicine distribution system, meet GMP aseptic requirements. Bioengineering: cell culture, fermentation tank pipelines, avoid cross contamination risks. Dairy industry: Milk and ingredient delivery pipelines, corrosion-resistant and easy to clean and disinfect. Cosmetics industry: High-viscosity raw material delivery, ensuring chemical compatibility. Semiconductor industry: Ultrapure water and chemical distribution, in line with clean room cleanliness levels.