| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Sanitary constant pressure reversing valve

The stainless steel sanitary constant-pressure directional valve is a multi-way valve designed for high-purity industries such as food, beverage, and pharmaceuticals. It maintains constant outlet pressure despite upstream fluctuations while switching flow paths, ensuring system stability and protecting equipment. Its crevice-free internal structure supports CIP/SIP, allowing hygienic operation without dead zones.

Working Principles

This stainless steel sanitary constant-pressure reversing valve combines a pressure control assembly and flow guide mechanism for automatic regulation and switching. It maintains stable outlet pressure by adjusting the valve core when upstream pressure fluctuates. Flow direction is switched via pneumatic or electric actuation, ensuring precise routing to different pipelines. Ideal for sanitary systems requiring consistent pressure and synchronized flow control.

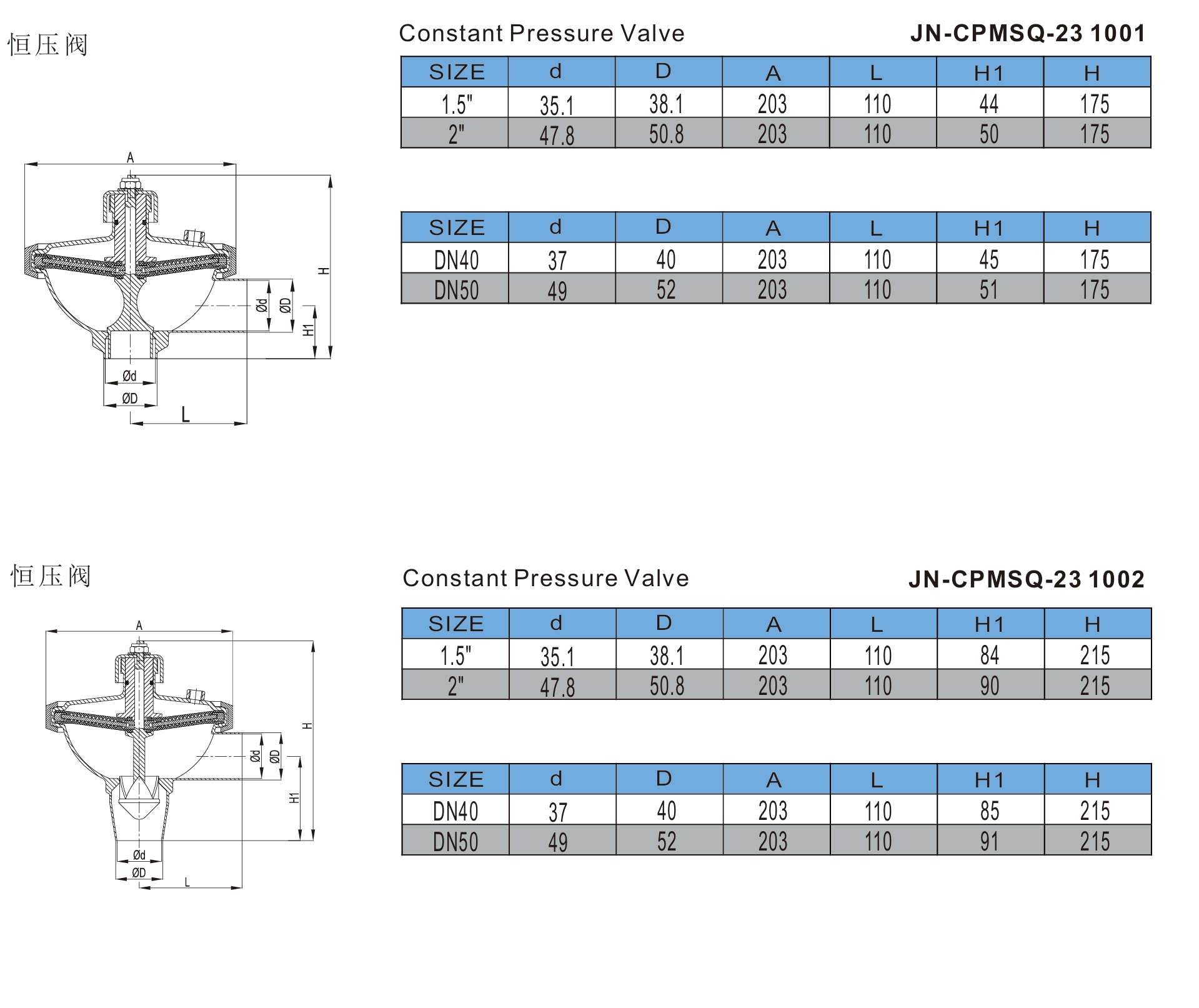

Stainless Steel Constant Pressure Valve Specification Chart

Valve Size | DN25-DN100/1” to 4“ |

Connection Type | Clamp, Weld, Thread |

Working Pressure Range | 0.2 to 6 bar |

Constant Pressure Range | 0.5 to 3.5 bar |

Operating Temperature | -10 °C to 135 °C |

Control Type | Pneumatic or Electric |

Surface Finish | Ra ≤ 0.8 µm |

| Seal Material | EPDM, PTFE, FKM |

| Body Material | SS304 or SS316L |

| Cleaning Compatibility | CIP/SIP |

Features

● A built-in constant pressure mechanism automatically adjusts outlet pressure to ensure stable system pressure and prevent pressure fluctuations from affecting the process.

● The internal flow path of the valve body is smooth and free of stagnant areas, meeting CIP/SIP cleaning requirements and ensuring a sterile production environment.

● The switching action is sensitive, with fast and smooth switching, making it suitable for fluid control processes with frequent changes.

● The modular design facilitates maintenance, upgrades, and flexible configuration for different piping layouts.

● Standard quick-release connectors facilitate assembly and disassembly, saving maintenance time and improving production efficiency.

● Elastic seals and precision machining combine to effectively prevent media leakage and enhance system safety.

Application

Stainless steel sanitary constant pressure directional valves are used in food, dairy, beverage, pharmaceutical, and bioengineering industries. In dairy filling lines, they ensure stable pressure and precise flow switching, supporting accurate filling and hygienic operation.

Working Principles

This stainless steel sanitary constant-pressure reversing valve combines a pressure control assembly and flow guide mechanism for automatic regulation and switching. It maintains stable outlet pressure by adjusting the valve core when upstream pressure fluctuates. Flow direction is switched via pneumatic or electric actuation, ensuring precise routing to different pipelines. Ideal for sanitary systems requiring consistent pressure and synchronized flow control.

Feature and Specification

Stainless Steel Constant Pressure Valve Specification Chart

Valve Size | DN25-DN100/1” to 4“ |

Connection Type | Clamp, Weld, Thread |

Working Pressure Range | 0.2 to 6 bar |

Constant Pressure Range | 0.5 to 3.5 bar |

Operating Temperature | -10 °C to 135 °C |

Control Type | Pneumatic or Electric |

Surface Finish | Ra ≤ 0.8 µm |

| Seal Material | EPDM, PTFE, FKM |

| Body Material | SS304 or SS316L |

| Cleaning Compatibility | CIP/SIP |

Features

● A built-in constant pressure mechanism automatically adjusts outlet pressure to ensure stable system pressure and prevent pressure fluctuations from affecting the process.

● The internal flow path of the valve body is smooth and free of stagnant areas, meeting CIP/SIP cleaning requirements and ensuring a sterile production environment.

● The switching action is sensitive, with fast and smooth switching, making it suitable for fluid control processes with frequent changes.

● The modular design facilitates maintenance, upgrades, and flexible configuration for different piping layouts.

● Standard quick-release connectors facilitate assembly and disassembly, saving maintenance time and improving production efficiency.

● Elastic seals and precision machining combine to effectively prevent media leakage and enhance system safety.

Application

Stainless steel sanitary constant pressure directional valves are used in food, dairy, beverage, pharmaceutical, and bioengineering industries. In dairy filling lines, they ensure stable pressure and precise flow switching, supporting accurate filling and hygienic operation.