| Availability: | |

|---|---|

| Quantity: | |

A stainless steel centrifugal pump is a mechanical device that moves liquids by converting rotational energy into kinetic energy. Made from stainless steel, it has excellent resistance to corrosion, rust and chemical damage, making it suitable for a wide range of applications in harsh environments. The pump uses a rotating impeller to create centrifugal force, which pushes the liquid outward into the discharge pipe as liquid enters through the pump's inlet. This type of pump is widely used due to its durability, efficiency and ability to handle high temperatures and pressures.

JONENG

8481804090

The stainless steel centrifugal pump uses a rotating impeller to generate centrifugal force to transport liquid from the inlet to the discharge pipe. It is made of corrosion-resistant stainless steel and has an impeller that generates centrifugal force to push the fluid through the system. It is currently the most widely used type of pump in industry.

Working Principles

The working principle of a stainless steel centrifugal pump is to convert mechanical energy into fluid energy. The pump consists of an impeller mounted in a casing. As the impeller rotates, the stainless steel centrifugal pump transfers kinetic energy to the liquid, which creates a centrifugal force. This force pushes the fluid outward, increasing the fluid's velocity. As the fluid leaves the impeller, its pressure increases and is directed to the pump's discharge pipe. The pump's inlet draws in more fluid to replace the discharged fluid, maintaining a continuous flow rate.

Stainless Steel Lobe Pump Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Max pressur | 7bar |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

Frequency | 50HZ/60HZ |

Features

● Corrosion resistance: The pump is made of stainless steel.

● Durability: Stainless steel has excellent strength and longevity.

● Hygienic design: Stainless steel has a smooth, non-porous surface and is easy to clean.

● Efficiency: The pump consumes little energy to operate.

● Versatility: It can handle a wide range of liquids.

● Low maintenance: It requires little maintenance and is easy to inspect and clean.

● High performance: It can provide stable flow and pressure for a long time.

● High temperature resistance: Stainless steel can withstand high temperatures.

Application

Stainless steel centrifugal pumps are widely used in various industries due to their durability, corrosion resistance and efficiency. The main application areas include: food and beverage industry, pharmaceutical industry, chemical processing industry, water treatment, cosmetics, agriculture, oil and gas, HVAC systems, marine.

Working Principles

The working principle of a stainless steel centrifugal pump is to convert mechanical energy into fluid energy. The pump consists of an impeller mounted in a casing. As the impeller rotates, the stainless steel centrifugal pump transfers kinetic energy to the liquid, which creates a centrifugal force. This force pushes the fluid outward, increasing the fluid's velocity. As the fluid leaves the impeller, its pressure increases and is directed to the pump's discharge pipe. The pump's inlet draws in more fluid to replace the discharged fluid, maintaining a continuous flow rate.

Specification

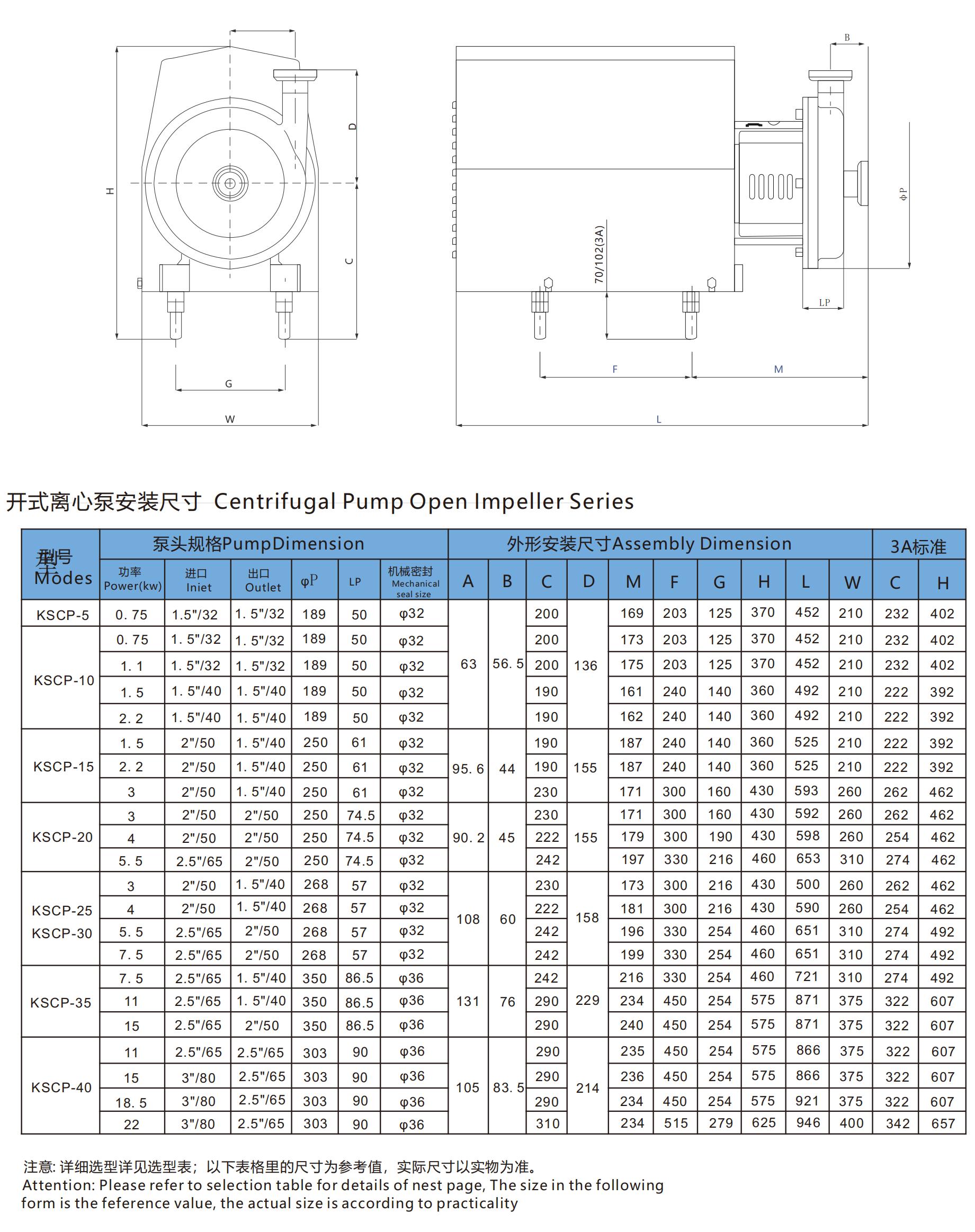

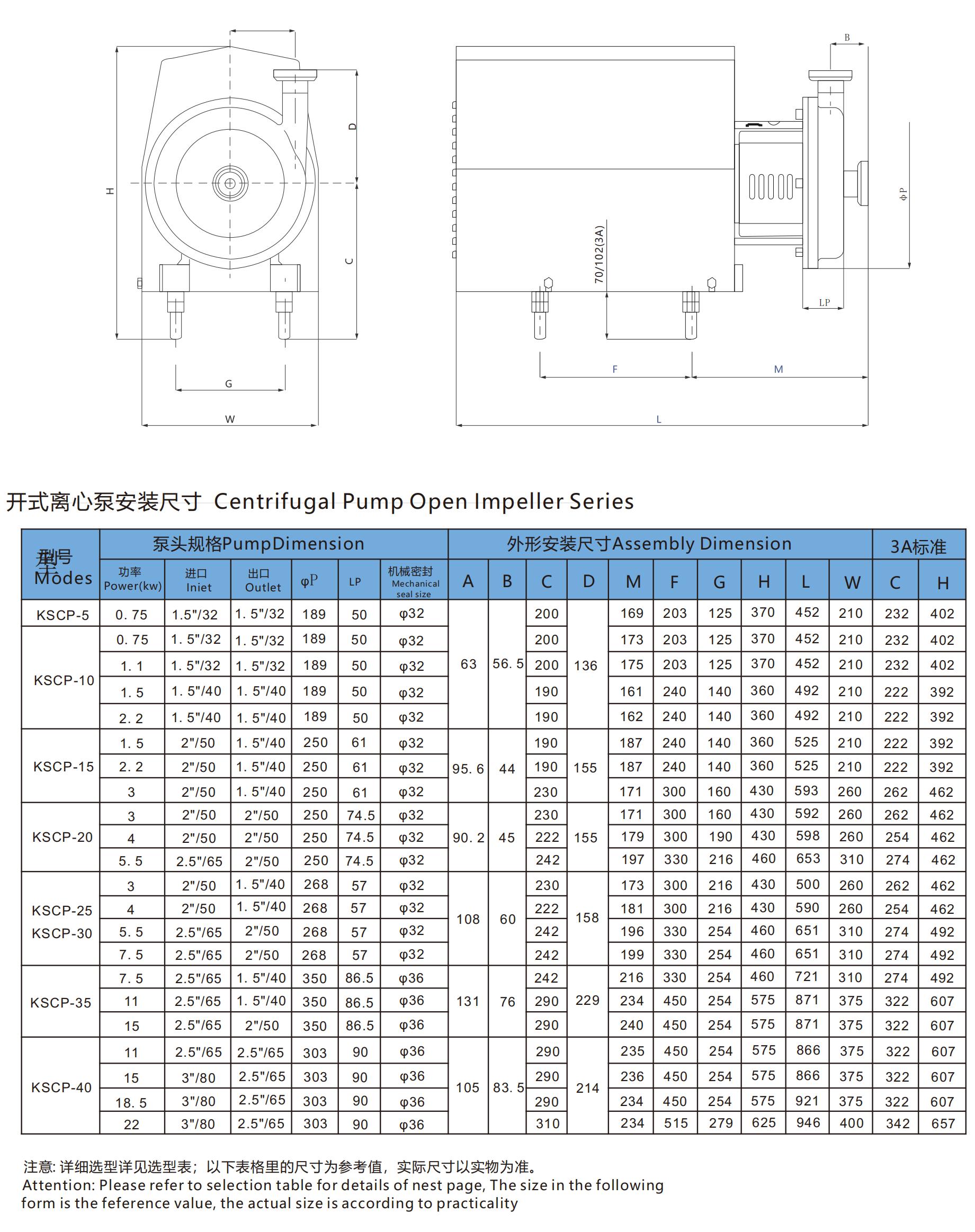

Stainless Steel Centrifugal Pump Specification Chart

Max. flow rate | 130m3/h |

Max viscosity | 100000Cps |

Power supply | 0.75kw to 30kw |

Max. temperature | 120 °C |

Material | SS304/SS316L |

| Mechanical seal | single mechanical seal/double mechanical seal |

| Inlet/outlet connection | Thread, Clamp, Flange,Weld,Union |

| Internal Surface treatment | ≤ Ra0.8μm as default |

| Motor brand | ABB or local motor |

| Motor type | variable frequency motor, fixed speed motor |

Frequency | 50HZ/60HZ |

Max. pressure | 7 bar |

Max. temperature | 120°C |

Material | SS304/SS316L |

| Inlet/outlet connection | Clamp, Weld, Flange |

| Inlet/outlet size | 1”-3” |

| Diaphragm | PTFE, PTFE with white back, EPDM, white EPDM, white NBR |

| Driving way | Air or Motor |

Features

● Corrosion resistance: The pump is made of stainless steel.

● Durability: Stainless steel has excellent strength and longevity.

● Hygienic design: Stainless steel has a smooth, non-porous surface and is easy to clean.

● Efficiency: The pump consumes little energy to operate.

● Versatility: It can handle a wide range of liquids.

● Low maintenance: It requires little maintenance and is easy to inspect and clean.

● High performance: It can provide stable flow and pressure for a long time.

● High temperature resistance: Stainless steel can withstand high temperatures.

Application

Stainless steel centrifugal pumps are widely used in various industries due to their durability, corrosion resistance and efficiency. The main application areas include: food and beverage industry, pharmaceutical industry, chemical processing industry, water treatment, cosmetics, agriculture, oil and gas, HVAC systems, marine.