| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless steel positioning micro-control proportional regulating flange diaphragm valve

The Stainless Steel Positioning Micro-Control Proportional Regulating Flange Diaphragm Valve is a sanitary precision valve with a diaphragm structure. It provides accurate, linear flow controlvia a micro-control actuator. Flanged connections ensure reliable sealing, making it ideal for food, pharmaceutical, biotech, and chemical systems requiring stable, high-precision regulation.

Working Principles

The Stainless Steel Positioning Micro-Control Proportional Regulating Flange Diaphragm Valve operates by using a micro-control actuator to convert electrical or pneumatic signals into precise mechanical movement. This movement adjusts the diaphragm, which opens or closes the flow passage proportionally to the input signal, allowing accurate flow regulation. A built-in feedback system continuously monitors the diaphragm position, correcting deviations to maintain the desired opening. The diaphragm design ensures a tight seal and prevents leakage, while the proportional control provides smooth, linear, and stable flow adjustment. This mechanism makes the valve ideal for high-precision applications in food, pharmaceutical, and sanitary systems.

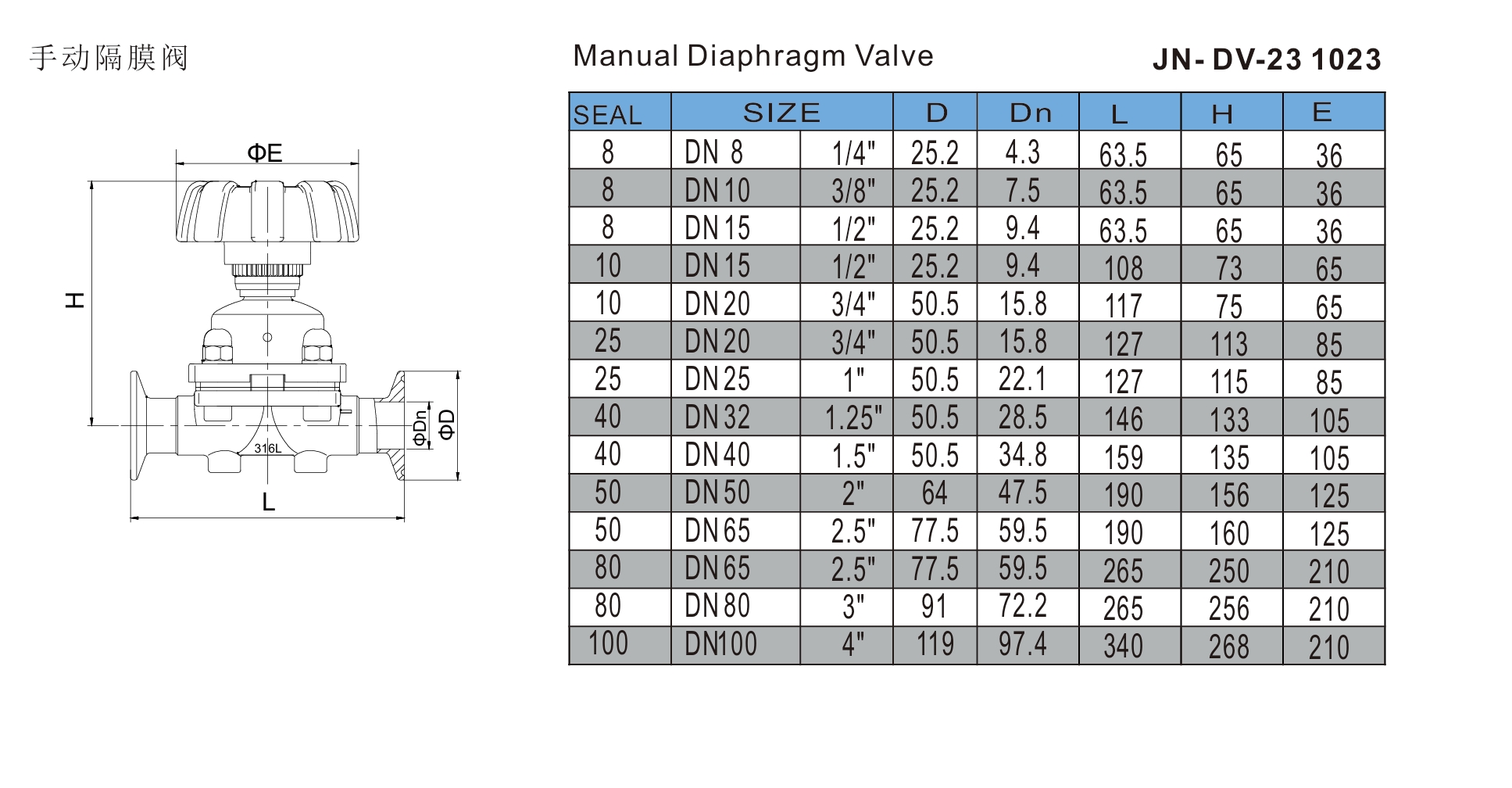

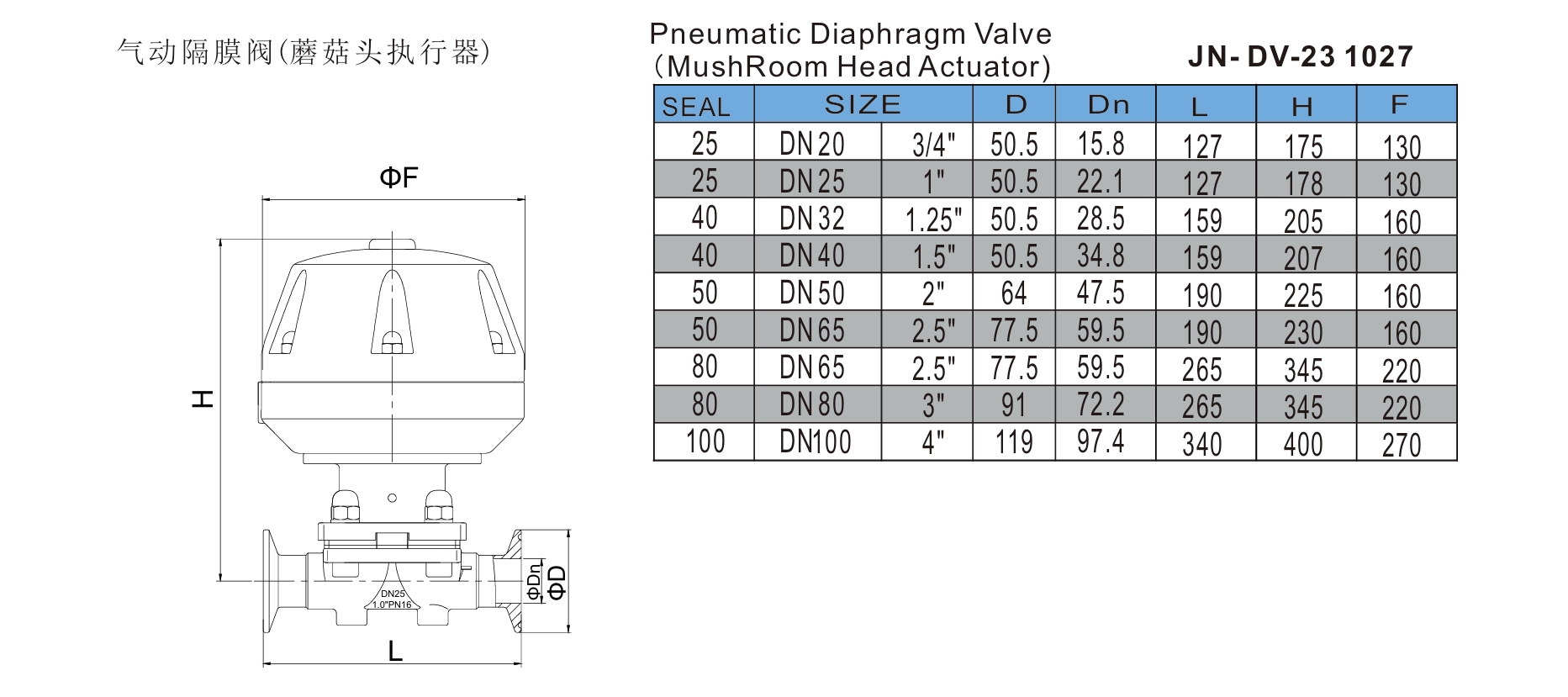

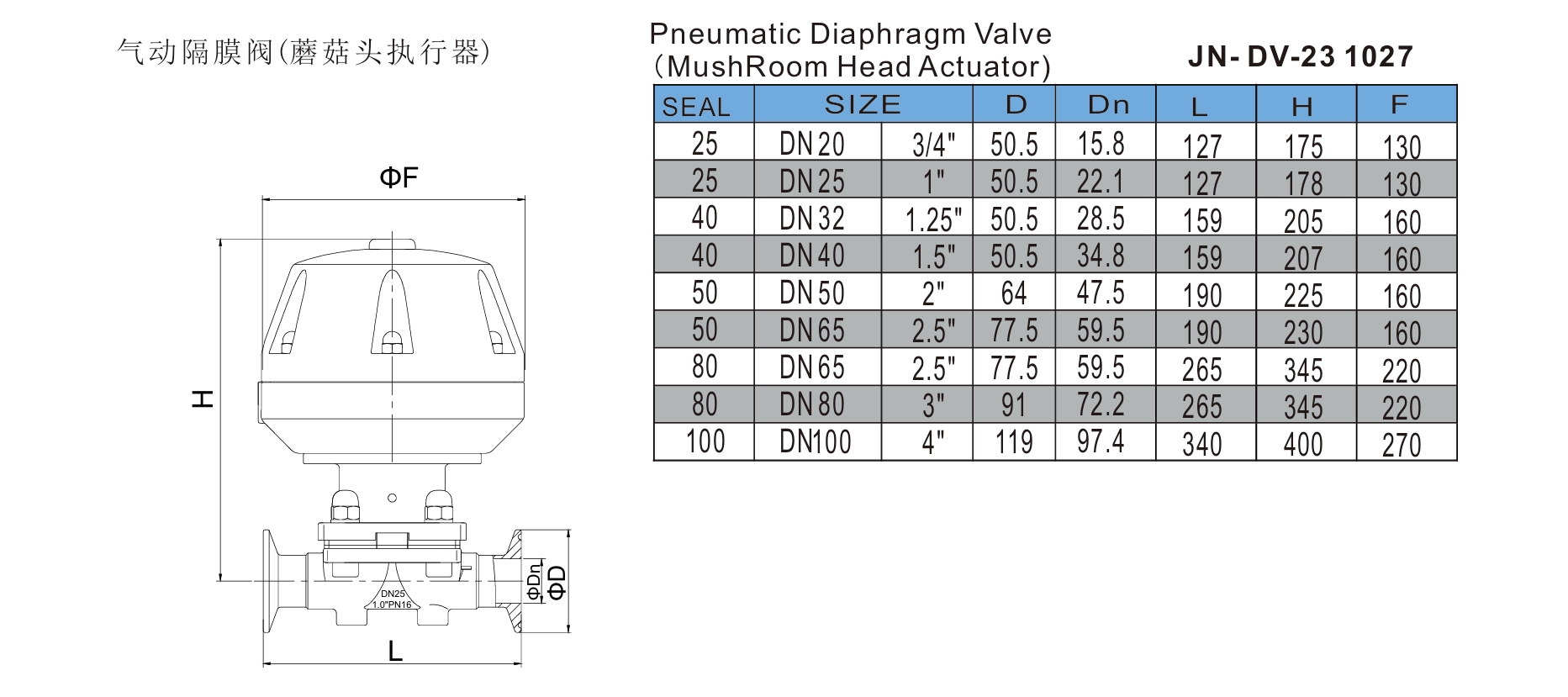

Stainless Steel Diaphragm Valve Specification Chart

Material | Stainless Steel 304 / 316L |

Valve Type | Diaphragm, Flanged, Proportional Regulating |

Actuator Type | Micro-Control Electric / Pneumatic |

Control Signal | 4–20 mA (Electric) / 0.2–1.0 MPa (Pneumatic) |

Flow Characteristic | Linear / Equal Percentage |

Connection Type | Flange (DIN, ANSI, or custom) |

Pressure Rating | PN16 / PN25 (depending on model) |

Temperature Range | -10°C to 150°C (standard), up to 200°C optional |

Seal Material | PTFE / EPDM / FDA-compliant options |

Response Time | 1–3 seconds (depending on actuator) |

| Applications | Food, Pharmaceutical, Biotech, Chemical, High-purity Systems |

Features

Precision Flow Control – Uses a micro-control actuator to achieve proportional and linear flow adjustment, ensuring accurate and stable process control.

Diaphragm Seal Design – The diaphragm provides a tight seal, prevents leakage, and allows hygienic handling of liquids and gases.

Stainless Steel Construction – Made of high-quality stainless steel, offering corrosion resistance, durability, and suitability for sanitary applications.

Flanged Connection – Flange design ensures strong installation, reliable sealing, and easy maintenance in piping systems.

Feedback Positioning System – Continuous position monitoring allows automatic correction, maintaining precise valve opening and stable flow under varying conditions.

Hygienic and Cleanable – Smooth, crevice-free surfaces comply with sanitary standards, reducing contamination risk and supporting food, pharmaceutical, and biotech processes.

Fast and Stable Response – Rapid actuator response with minimal hysteresis ensures consistent performance and precise process control.

Application

The Stainless Steel Positioning Micro-Control Proportional Regulating Flange Diaphragm Valve is widely used in industries requiring precise and hygienic flow control. Typical applications include food and beverage processing, pharmaceutical manufacturing, biotechnology, and chemical production, where accurate dosing, sterile handling, and stable process control are critical.

Working Principles

The Stainless Steel Positioning Micro-Control Proportional Regulating Flange Diaphragm Valve operates by using a micro-control actuator to convert electrical or pneumatic signals into precise mechanical movement. This movement adjusts the diaphragm, which opens or closes the flow passage proportionally to the input signal, allowing accurate flow regulation. A built-in feedback system continuously monitors the diaphragm position, correcting deviations to maintain the desired opening. The diaphragm design ensures a tight seal and prevents leakage, while the proportional control provides smooth, linear, and stable flow adjustment. This mechanism makes the valve ideal for high-precision applications in food, pharmaceutical, and sanitary systems.

Feature and Specification

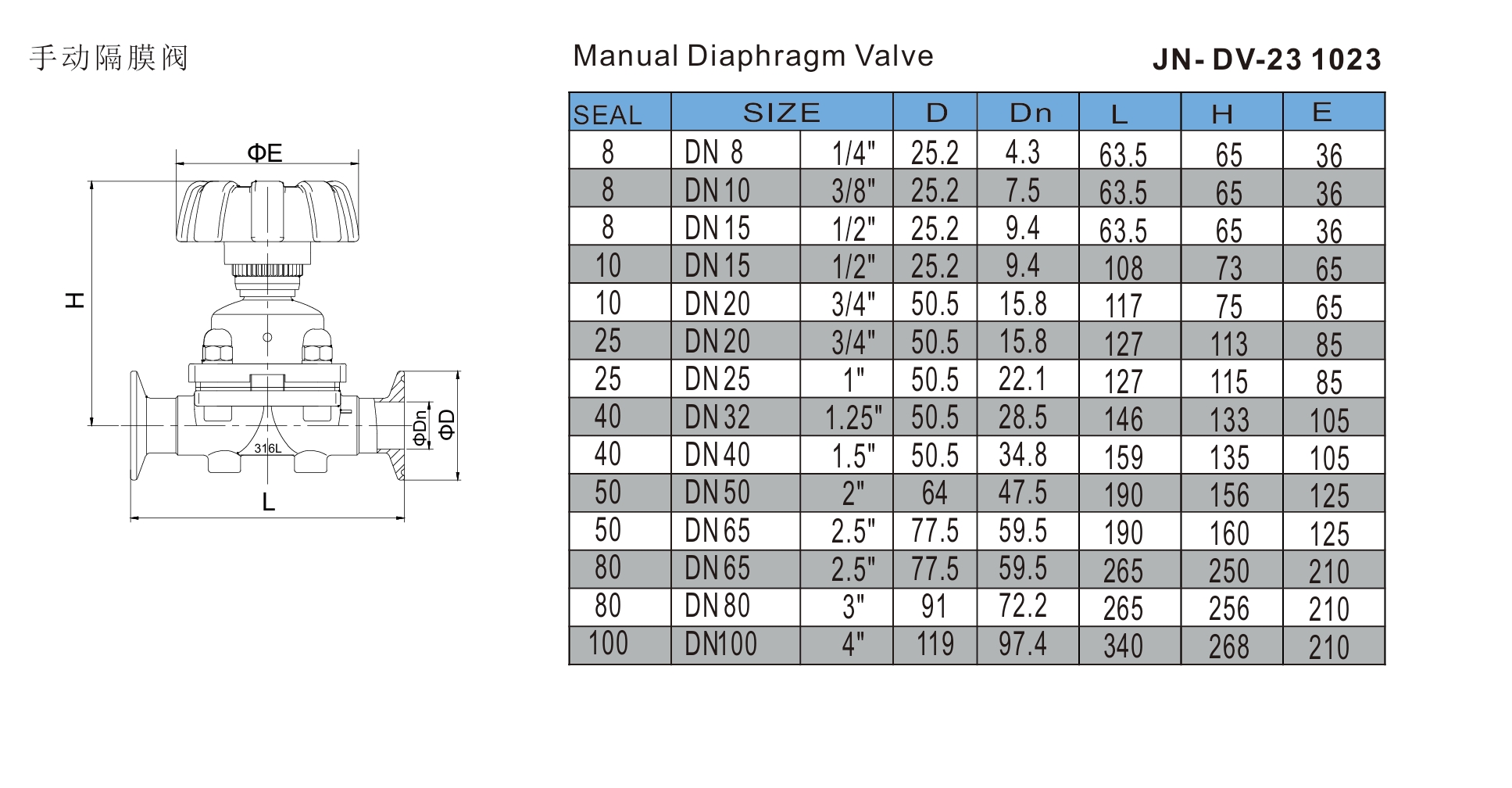

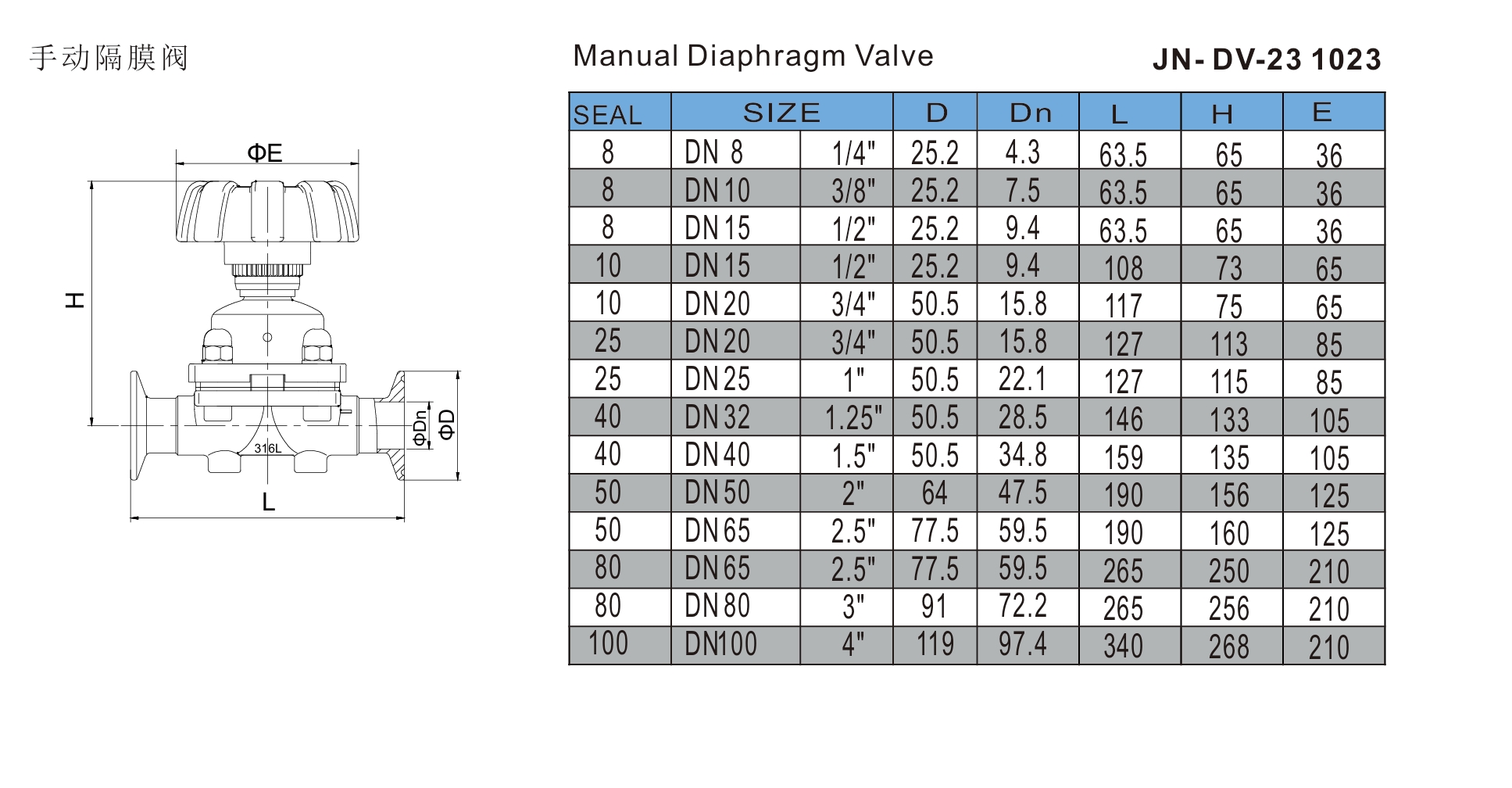

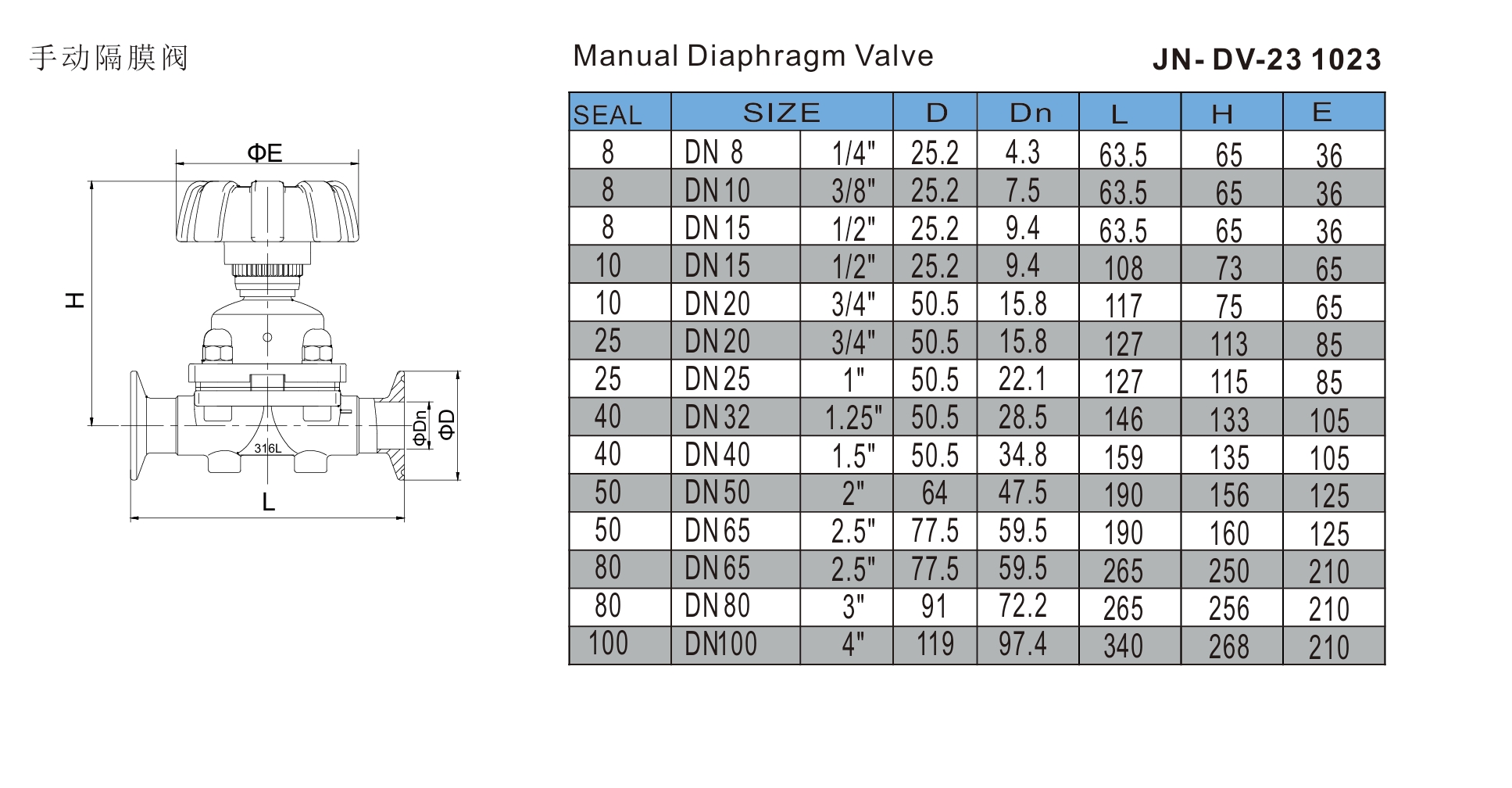

Stainless Steel Diaphragm Valve Specification Chart

Valve Type | Manual Welded U-Type Diaphragm Valve |

Connection Type | Welded Ends |

Nominal Sizes | DN10-DN100/1/2-4” |

Working Pressure | 0-10 bar |

Operating Temperature | -10°C to to 150°C |

Flow Pattern | Straight-through (U-Type) |

Body Surface Finish | Ra ≤ 0.6 μm (inner), Ra ≤ 1.2 μm (outer) |

Cleaning Compatibility | CIP/SIP |

Diaphragm Materials | EPDM, EPDM+PTFE, FPM |

Body Materials | AISI 316L/AISI 304 |

| Handwheel Material | Stainless Steel / Plastic / Aluminum Alloy |

| Mounting Orientation | Horizontal or Vertical |

Features

Precision Flow Control – Uses a micro-control actuator to achieve proportional and linear flow adjustment, ensuring accurate and stable process control.

Diaphragm Seal Design – The diaphragm provides a tight seal, prevents leakage, and allows hygienic handling of liquids and gases.

Stainless Steel Construction – Made of high-quality stainless steel, offering corrosion resistance, durability, and suitability for sanitary applications.

Flanged Connection – Flange design ensures strong installation, reliable sealing, and easy maintenance in piping systems.

Feedback Positioning System – Continuous position monitoring allows automatic correction, maintaining precise valve opening and stable flow under varying conditions.

Hygienic and Cleanable – Smooth, crevice-free surfaces comply with sanitary standards, reducing contamination risk and supporting food, pharmaceutical, and biotech processes.

Fast and Stable Response – Rapid actuator response with minimal hysteresis ensures consistent performance and precise process control.

Application

The Stainless Steel Positioning Micro-Control Proportional Regulating Flange Diaphragm Valve is widely used in industries requiring precise and hygienic flow control. Typical applications include food and beverage processing, pharmaceutical manufacturing, biotechnology, and chemical production, where accurate dosing, sterile handling, and stable process control are critical.