| Availability: | |

|---|---|

| Quantity: | |

JN-BV 1008

JONENG

8481804090

Stainless Steel Sanitary EPDM Duckbill Quick-install Manual Butterfly Valve

The stainless steel sanitary duckbill quick-install manual butterfly valve is designed to provide convenient installation, disassembly and cleaning functions while accurately adjusting the flow of fluids. Its "duckbill" structure not only enhances the sealing of the valve body, but also ensures that the valve maintains sanitary standards during frequent disassembly and cleaning. Compared with traditional butterfly valves, this design is particularly suitable for occasions that require efficient cleaning and high hygiene requirements, such as food, beverage, pharmaceutical and other industries. Its simple quick-install interface and manual operation mode enable the equipment to quickly resume production, improving the efficiency and safety of the production line.

Working Principles

The working principle of the stainless steel sanitary duckbill quick-install manual butterfly valve is to rotate the handle to drive the valve stem, so that the valve plate rotates 90 degrees in the valve body, thereby realizing the opening and closing of the valve. First, the rotation force of the handle is transmitted to the valve stem, and the valve stem drives the valve plate to rotate; when the valve plate rotates to be parallel to the pipeline, the valve is fully opened and the medium can pass freely; when the valve plate rotates to be perpendicular to the pipeline, the valve is closed to block the flow of the medium.

The options of the stainless steel sanitary duckbill quick-install manual butterfly valve include:

Sealing materials: such as EPDM, PTFE, NBR, etc.

Connection method: quick-install interface, thread, flange connection, etc.

Drive mode: manual operation, pneumatic drive.

Valve plate type: disc type, butterfly plate.

Pressure level: selected according to the working pressure.

Valve body material: 304 stainless steel, 316L stainless steel.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

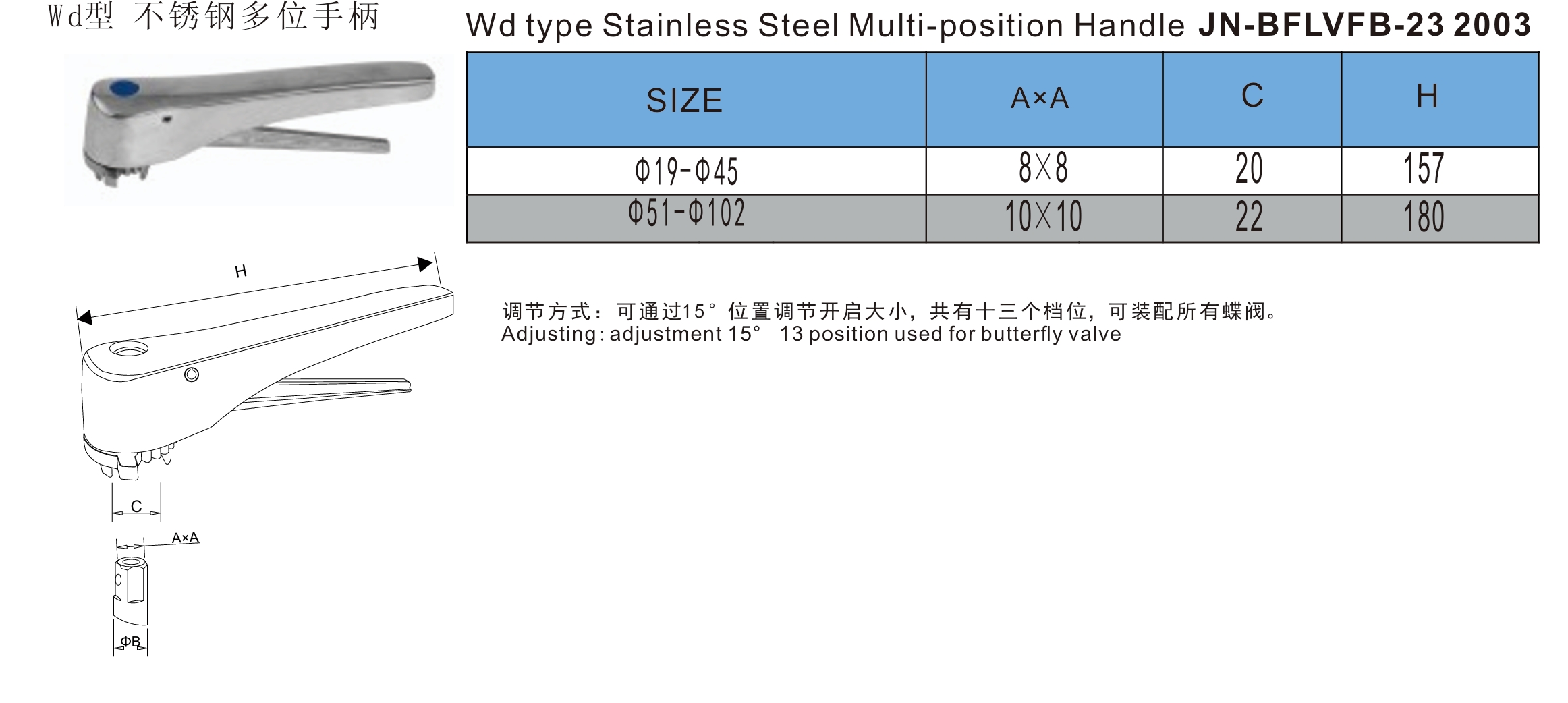

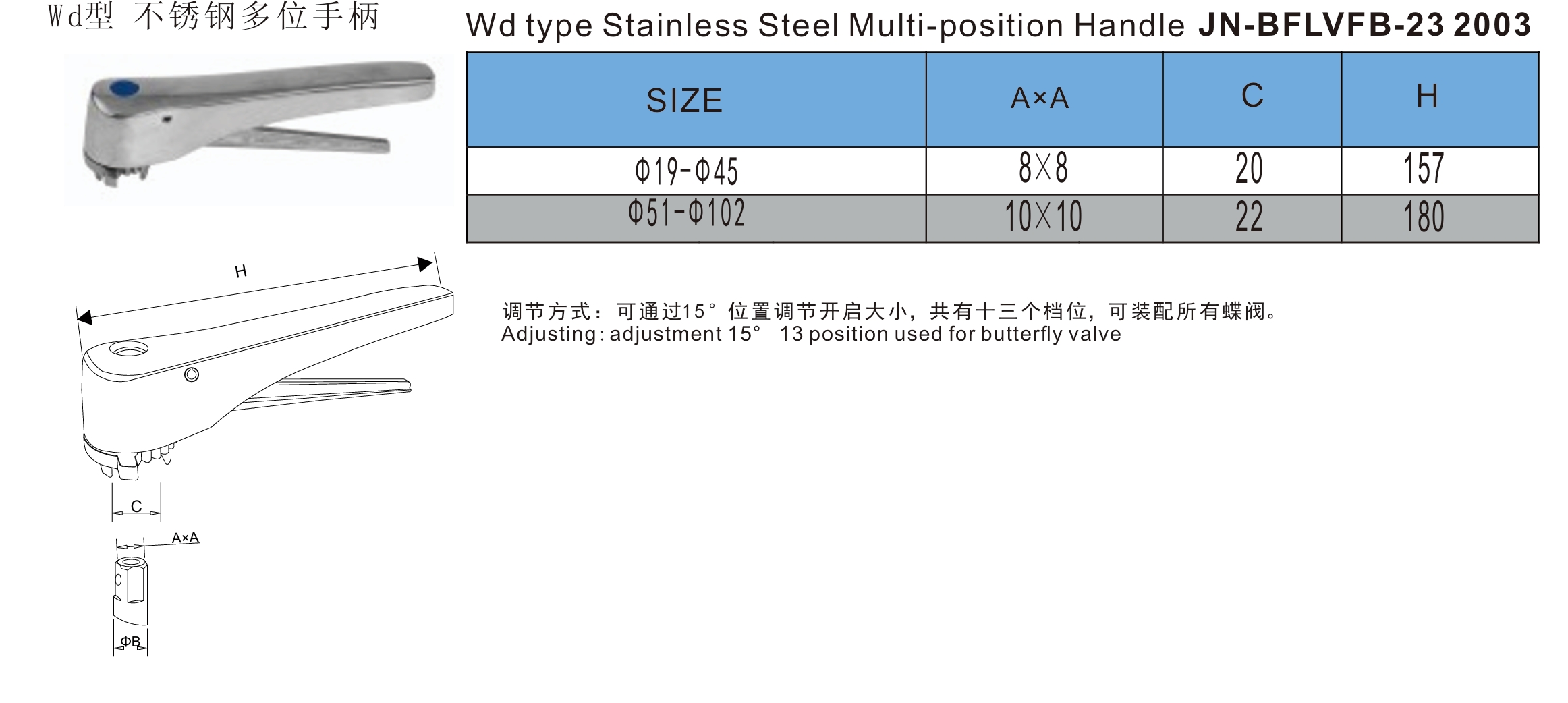

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● The stainless steel sanitary duckbill quick-install manual butterfly valve adopts a dead angle-free design, and all fluid contact surfaces are smooth inner surfaces.

● The stainless steel sanitary duckbill quick-install manual butterfly valve adopts a two-way sealing structure, which can ensure that it can remain completely sealed when the fluid flow direction changes to prevent leakage.

● The stainless steel sanitary duckbill quick-install manual butterfly valve is designed with a valve plate automatic calibration mechanism, which can automatically adjust the valve plate position during operation to ensure flow accuracy.

● The stainless steel sanitary duckbill quick-install manual butterfly valve has a quick sealing mechanism, which can complete the sealing of the valve body and the valve plate in an instant to prevent fluid leakage.

● The inner and outer surfaces of the stainless steel sanitary duckbill quick-install manual butterfly valve are treated with antibacterial coating to effectively inhibit the growth of bacteria and microorganisms.

● The stainless steel sanitary duckbill quick-install manual butterfly valve has an internal and external adjustable flow control device, which can accurately adjust the flow according to demand.

Application

Stainless steel sanitary duckbill quick-install manual butterfly valves are widely used in the following industries: Food industry: used for precise fluid control of food raw materials and finished products. Beverage industry: used for the delivery and flow control of juice and carbonated beverages. Pharmaceutical industry: to ensure the pollution-free and sanitary control of the flow of liquid medicine. Cosmetic industry: used for the flow control of cosmetic materials such as lotions and creams. Dairy industry: to accurately control the flow of fluids such as milk and cream. Chemical industry: used for the delivery of chemicals and corrosive substances. Water treatment industry: to deliver water treatment agents and chemical additives.

Working Principles

The working principle of the stainless steel sanitary duckbill quick-install manual butterfly valve is to rotate the handle to drive the valve stem, so that the valve plate rotates 90 degrees in the valve body, thereby realizing the opening and closing of the valve. First, the rotation force of the handle is transmitted to the valve stem, and the valve stem drives the valve plate to rotate; when the valve plate rotates to be parallel to the pipeline, the valve is fully opened and the medium can pass freely; when the valve plate rotates to be perpendicular to the pipeline, the valve is closed to block the flow of the medium.

The options of the stainless steel sanitary duckbill quick-install manual butterfly valve include:

Sealing materials: such as EPDM, PTFE, NBR, etc.

Connection method: quick-install interface, thread, flange connection, etc.

Drive mode: manual operation, pneumatic drive.

Valve plate type: disc type, butterfly plate.

Pressure level: selected according to the working pressure.

Valve body material: 304 stainless steel, 316L stainless steel.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Features

● The stainless steel sanitary duckbill quick-install manual butterfly valve adopts a dead angle-free design, and all fluid contact surfaces are smooth inner surfaces.

● The stainless steel sanitary duckbill quick-install manual butterfly valve adopts a two-way sealing structure, which can ensure that it can remain completely sealed when the fluid flow direction changes to prevent leakage.

● The stainless steel sanitary duckbill quick-install manual butterfly valve is designed with a valve plate automatic calibration mechanism, which can automatically adjust the valve plate position during operation to ensure flow accuracy.

● The stainless steel sanitary duckbill quick-install manual butterfly valve has a quick sealing mechanism, which can complete the sealing of the valve body and the valve plate in an instant to prevent fluid leakage.

● The inner and outer surfaces of the stainless steel sanitary duckbill quick-install manual butterfly valve are treated with antibacterial coating to effectively inhibit the growth of bacteria and microorganisms.

● The stainless steel sanitary duckbill quick-install manual butterfly valve has an internal and external adjustable flow control device, which can accurately adjust the flow according to demand.

Application

Stainless steel sanitary duckbill quick-install manual butterfly valves are widely used in the following industries: Food industry: used for precise fluid control of food raw materials and finished products. Beverage industry: used for the delivery and flow control of juice and carbonated beverages. Pharmaceutical industry: to ensure the pollution-free and sanitary control of the flow of liquid medicine. Cosmetic industry: used for the flow control of cosmetic materials such as lotions and creams. Dairy industry: to accurately control the flow of fluids such as milk and cream. Chemical industry: used for the delivery of chemicals and corrosive substances. Water treatment industry: to deliver water treatment agents and chemical additives.