| Availability: | |

|---|---|

| Quantity: | |

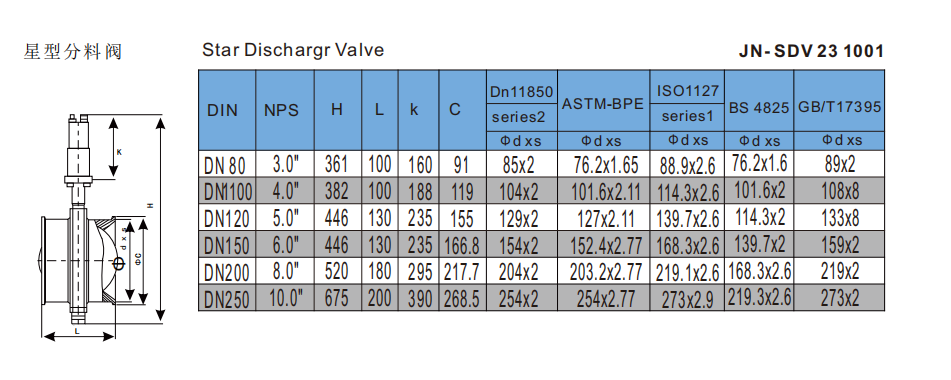

JN- SDV 23 1001

JONENG

8481804090

316/316L Food Gradequick Assembly Oscillating Disc Dosing Valve JN- SDV 23 1001

A stainless steel star discharge valve is a type of industrial valve specifically designed for controlling the discharge or release of materials from a processing system or vessel. These valves are commonly used in various industries such as food and beverage, pharmaceuticals, chemicals, and other processing applications.

Working Principles

The working principle of a star discharge valve involves the controlled rotation of a star-shaped rotor within a valve housing. This rotation creates openings or channels through which bulk material can flow, allowing for precise regulation of the discharge rate.

Stainless Steel Butterfly Valve Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

Precise flow control

Light weight

Sanitary design

Minimized material clogging

Ease of maintenance and cleaning

Durability and versatility

Improved process efficiency

Environmental friendly

Application

Star discharge valves find applications in various industries where controlled and precise discharge of bulk materials is essential. Some common applications include food and beverage industry, pharmaceutical, chemical, cosmetic and personal care, and other industries including food processing industries.

Working Principles

The pneumatic actuator with a single spring return design or double air acting design. The compressed air pushes the core piston in the pneumatic actuator to compress downward to drive the rotary head so that the rotary head rotate 90 degree, and the square core is connected with the pneumatic actuator and valve disc to drive the valve to be open and close. The valve is opened or closed according to the flow of the control medium in the pipeline

Feature and Specification

Stainless Steel Butterfly Valve Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Required compressed air | 4-8Bar |

Connection of compressed air | G 1/8’’ |

Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● Seats and seals comply with FDA approved

● Special gasket design, fluid free of residue

● Better acid proof, alkali proof

● Small torque, light weight,simple structure

● 360 degree installation

● 100% tested and inspected

● Cost-efficient leakage protection

● More than thirty thousand safety test

● Low pressure losses

● Thorough cleaning,Hygienic exterior design

● Minimize turbulence and maximize fluid flow trough

Application

Sanitary Butterfly valve widely use in low and medium viscosity liquid for food and beverage, beer, dairy, pharmaceutical etc with high precision and purity requirements industries.