| Availability: | |

|---|---|

| Quantity: | |

JN-NRV 1007

JONENG

8481804090

SS316L Food Grade Top Quality 3 Middle-union Check Valve

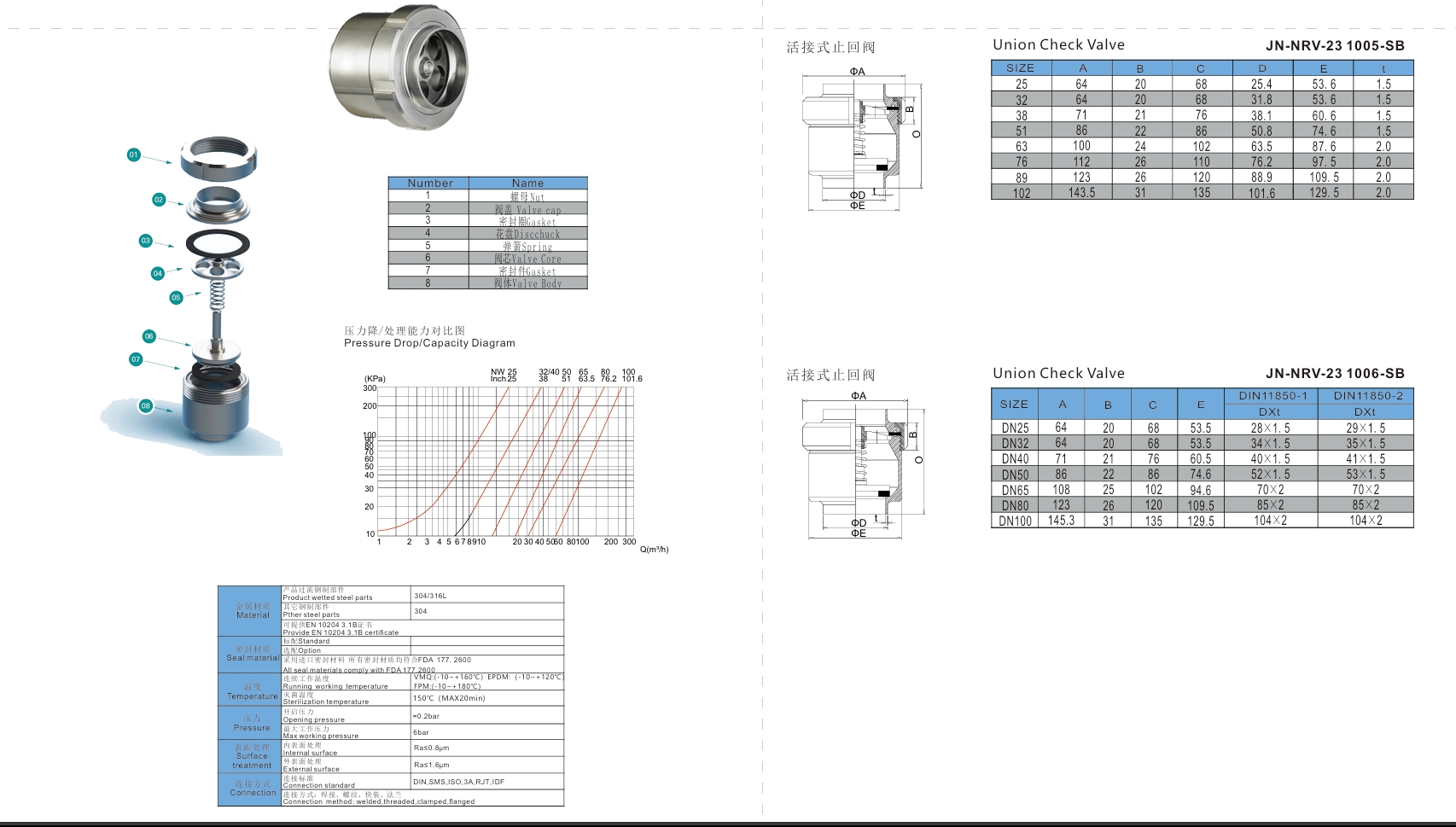

The check valves are also called sanitary spring check valve, sanitary disk check valve, non return valve, NRV. The sanitary check valve is made of stainless steel SUS304 and 316L, which can meet the special requirements of various media in the fields of food and bio pharmaceuticals. The smooth, seamless, and automatic emptying handicraft fluid channels are also very suitable for steam and in-place cleaning.

Working Principles

The check valve ( non return valve) is normally working automatically, it is closed if no media flow. When the pressure of the fluid is heavier than the pressure of the spring, the check valve opens automatically. When the two pressure are equalized, the valve closes. A stronger counter-pressure allows the valve to close.

Stainless Steel Angle Seat Valve Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries | |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred | |

The min. pressure difference is 0.08bar to open the valve | |

Flow direction is from the bottom to the top side only | |

Precision machined body, stem, disc, free draining | |

Disc tapered for smooth body and reduce draining | |

The check valves can not be used for sticky ,adhesive, viscous products. | |

Features

● Without any dead corners and gaps, 100% fit

● All kinds of connection type can be customized

● Aseptic, Non retention dead angle, easy to clean, easy to maintenance

● Simple construction, easy to installation and easy to control

● Compact design, easy maintenance and high torque

● All gaskets are FDA approved

● Absolute seating

● Minimize turbulence and bacteria traps

● Fully material trace-ability

Application

Sanitary check valves are widely used to prevent the liquid flowing from revering direction.The check valves can ensure the fluid flow in one way direction and inhibit the fluid flow back.

It is suitable for use in the food, beverage, biotech, pharmaceutical, and other hygienic applications.

Working Principle

The check valve ( non return valve) is normally working automatically, it is closed if no media flow. When the pressure of the fluid is heavier than the pressure of the spring, the check valve opens automatically. When the two pressure are equalized, the valve closes. A stronger counter-pressure allows the valve to close.

Feature

● Without any dead corners and gaps, 100% fit

● All kinds of connection type can be customized

● Aseptic, Non retention dead angle, easy to clean, easy to maintenance

● Simple construction, easy to installation and easy to control

● Compact design, easy maintenance and high torque

● All gaskets are FDA approved

● Absolute seating

● Minimize turbulence and bacteria traps

● Fully material trace-ability

Stainless Steel Angle Seat Valve Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries | |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred | |

The min. pressure difference is 0.08bar to open the valve | |

Flow direction is from the bottom to the top side only | |

Precision machined body, stem, disc, free draining | |

Disc tapered for smooth body and reduce draining | |

The check valves can not be used for sticky ,adhesive, viscous products. | |