| Availability: | |

|---|---|

| Quantity: | |

JN-BV 1007

JONENG

8481804090

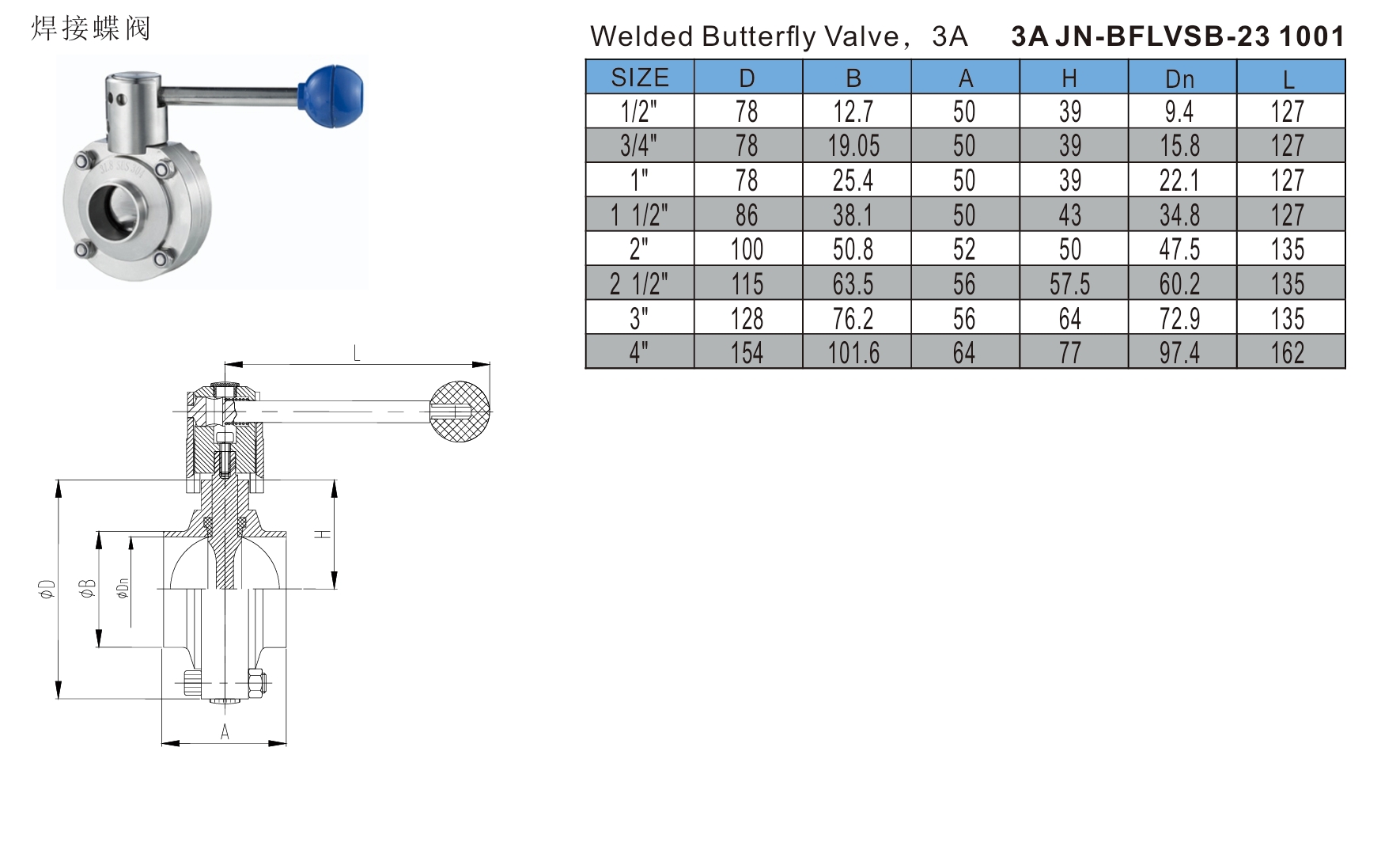

Stainless Steel Sanitary Welded Manual Butterfly Valve with Lever Handle

The stainless steel sanitary welded manual butterfly valve with a lever handle is designed to provide more precise and stable flow control, especially in pipeline systems where fluid regulation is frequent and high operating force is required. Through the handle with a lever, the operator can easily control the opening and closing of the valve under large flow and high pressure environments. This design is particularly suitable for industries that require strict hygiene standards to ensure that the fluid is not contaminated during the flow process, while providing reliable sealing and flow control. The welded structure also enhances the sealing and durability of the valve, and is suitable for long-term high-frequency operation.

Working Principles

The working principle of the stainless steel sanitary welded manual butterfly valve with a lever handle is to manually operate the lever handle to rotate the connected butterfly plate in the valve body. During operation, the lever handle drives the butterfly plate to rotate, and the butterfly plate gradually rotates to a closed or open state. When opening, the plane of the butterfly plate will be parallel to the flow direction of the pipeline fluid, forming a channel through which the fluid can pass freely; when closing, the butterfly plate rotates to a vertical position, completely closing the pipeline and cutting off the fluid flow. Through this simple and efficient manual operation, users can accurately adjust the flow or achieve emergency closure.

The options of the stainless steel sanitary welded manual butterfly valve with a lever handle include:

Material: 304 or 316L stainless steel.

Sealing material: fluororubber, silicone, PTFE, etc.

Connection method: welding, flange connection.

Handle type: lever, handwheel, lever.

Valve plate design: flat plate, butterfly type, etc.

Surface treatment: polishing, sandblasting, pickling.

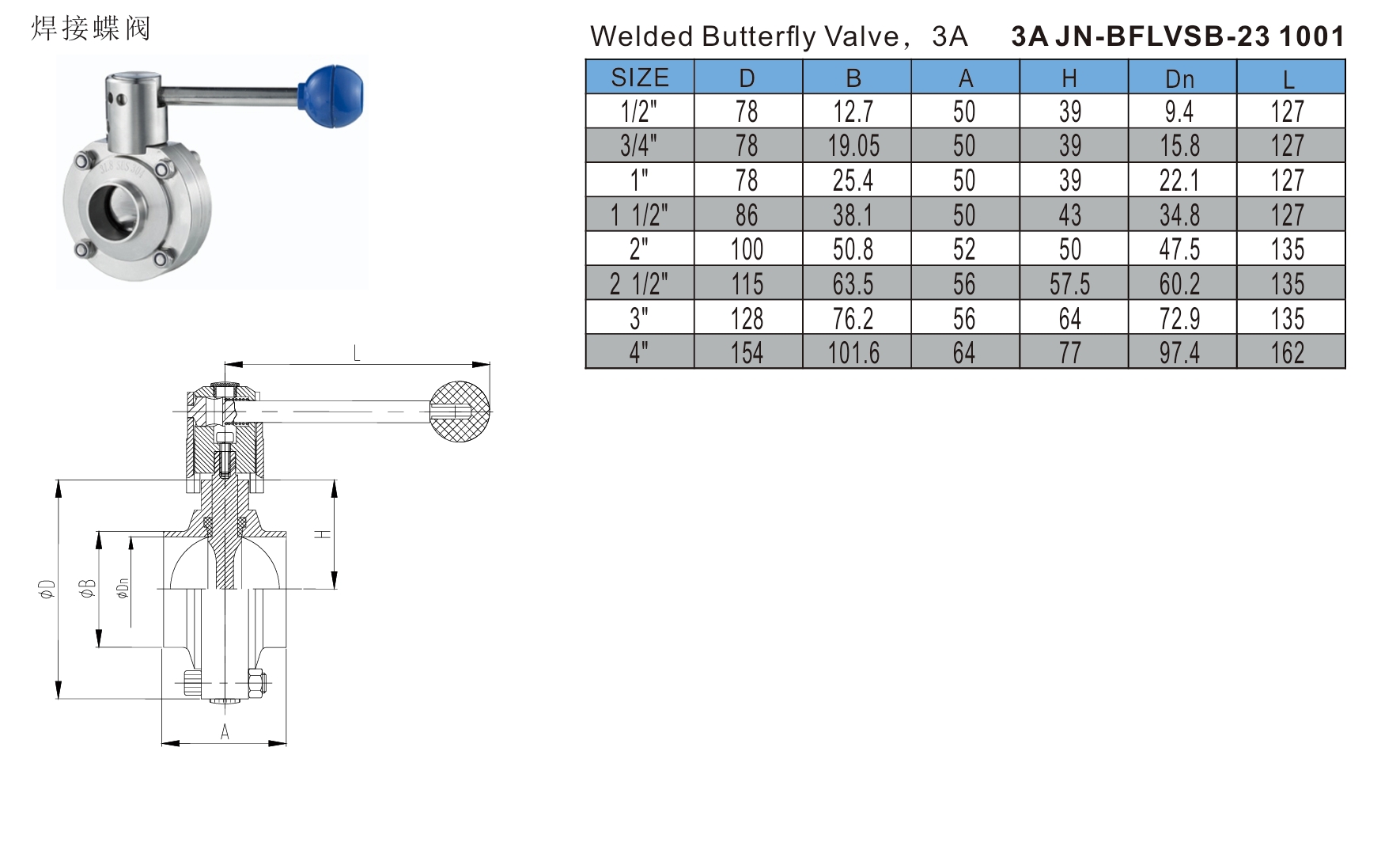

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● The butterfly plate and valve body of the stainless steel sanitary welded manual butterfly valve with a lever handle are reinforced and can withstand higher operating pressures.

● The stainless steel sanitary welded manual butterfly valve with a lever handle adopts a precise valve structure design, which enables accurate flow regulation even under large flow conditions.

● The stainless steel sanitary welded manual butterfly valve with a lever handle adopts a double seal design, and high-performance sealing materials are used between the valve body and the butterfly plate to ensure ultra-high sealing effect when closed.

● The design of the stainless steel sanitary welded manual butterfly valve with a lever handle allows users to quickly disassemble, clean and maintain.

● The butterfly plate and bearing of the stainless steel sanitary welded manual butterfly valve with a lever handle are specially designed to reduce the torque required during operation.

● The stainless steel sanitary welded manual butterfly valve with a lever handle has a two-way flow function and can support reverse flow of liquid or gas.

Application

Stainless steel sanitary welded manual butterfly valves with pull rod handles are widely used in the following industries: Food processing: used to accurately control fluid flow to ensure hygiene and safety. Pharmaceutical industry: control fluid flow in a sterile environment to meet hygiene standards. Chemical industry: used for precise flow regulation of corrosive or high-temperature fluids. Beverage manufacturing: Maintaining the flow of fluids without contamination, suitable for perishable liquids. Dairy production: Ensure that fluids are free of contamination and leakage during processing. Water treatment: Used to regulate the flow of water in pipes to ensure smooth flow. Cosmetic production: Regulate the flow of fluids to avoid contamination of finished products.

Working Principles

The working principle of the stainless steel sanitary welded manual butterfly valve with a lever handle is to manually operate the lever handle to rotate the connected butterfly plate in the valve body. During operation, the lever handle drives the butterfly plate to rotate, and the butterfly plate gradually rotates to a closed or open state. When opening, the plane of the butterfly plate will be parallel to the flow direction of the pipeline fluid, forming a channel through which the fluid can pass freely; when closing, the butterfly plate rotates to a vertical position, completely closing the pipeline and cutting off the fluid flow. Through this simple and efficient manual operation, users can accurately adjust the flow or achieve emergency closure.

The options of the stainless steel sanitary welded manual butterfly valve with a lever handle include:

Material: 304 or 316L stainless steel.

Sealing material: fluororubber, silicone, PTFE, etc.

Connection method: welding, flange connection.

Handle type: lever, handwheel, lever.

Valve plate design: flat plate, butterfly type, etc.

Surface treatment: polishing, sandblasting, pickling.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Features

● The butterfly plate and valve body of the stainless steel sanitary welded manual butterfly valve with a lever handle are reinforced and can withstand higher operating pressures.

● The stainless steel sanitary welded manual butterfly valve with a lever handle adopts a precise valve structure design, which enables accurate flow regulation even under large flow conditions.

● The stainless steel sanitary welded manual butterfly valve with a lever handle adopts a double seal design, and high-performance sealing materials are used between the valve body and the butterfly plate to ensure ultra-high sealing effect when closed.

● The design of the stainless steel sanitary welded manual butterfly valve with a lever handle allows users to quickly disassemble, clean and maintain.

● The butterfly plate and bearing of the stainless steel sanitary welded manual butterfly valve with a lever handle are specially designed to reduce the torque required during operation.

● The stainless steel sanitary welded manual butterfly valve with a lever handle has a two-way flow function and can support reverse flow of liquid or gas.

Application

Stainless steel sanitary welded manual butterfly valves with pull rod handles are widely used in the following industries: Food processing: used to accurately control fluid flow to ensure hygiene and safety. Pharmaceutical industry: control fluid flow in a sterile environment to meet hygiene standards. Chemical industry: used for precise flow regulation of corrosive or high-temperature fluids. Beverage manufacturing: Maintaining the flow of fluids without contamination, suitable for perishable liquids. Dairy production: Ensure that fluids are free of contamination and leakage during processing. Water treatment: Used to regulate the flow of water in pipes to ensure smooth flow. Cosmetic production: Regulate the flow of fluids to avoid contamination of finished products.