| Availability: | |

|---|---|

| Quantity: | |

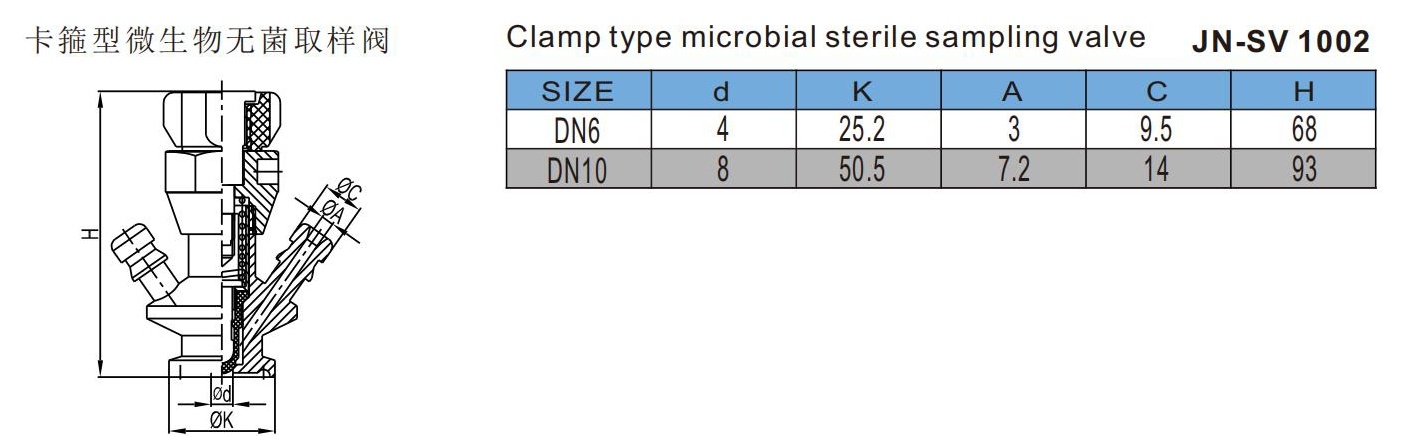

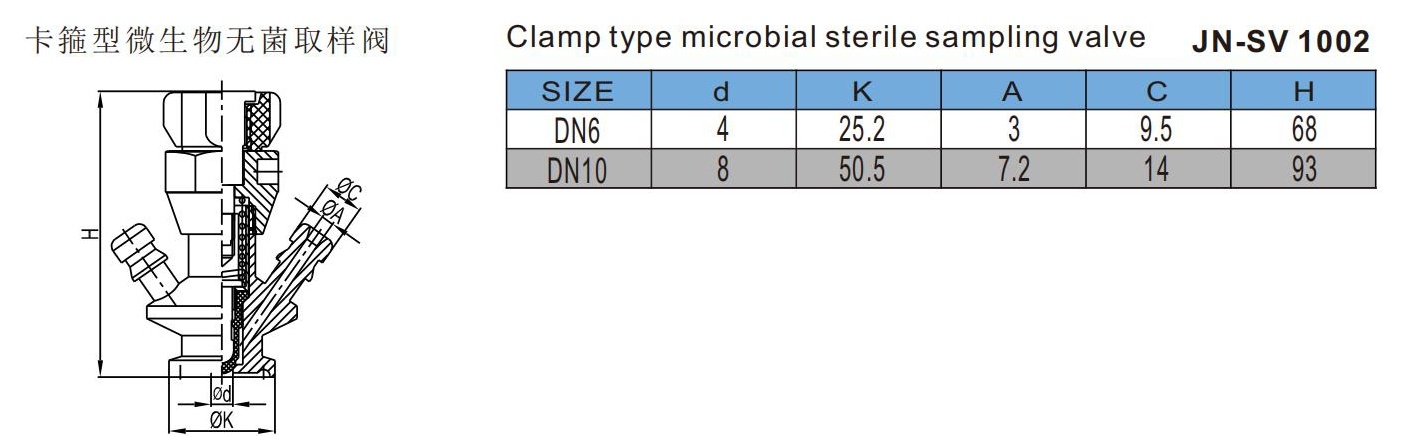

JN SV 1002

JONENG

8481804090

SS316L Sanitary 2-Way Output Welding Liquid Sampling Valve for Wine

A sanitary sampling valve is used to extract representative samples from a bulk fluid system or process. The sampling valves are designed to ensure the sample obtained is representative of the overall fluid stream without bringing contaminants or altering the properties of the fluid. The sampling valves are also assembled at the bottom of a tank or pipeline to drain away the remains.

Working Principles

When the valve is open, it allows a small portion of the liquid to flow through and we get the sample collected and analyzed. We need to turn the hand wheel clockwise,the valve shaft and seal rise up, value is open for sampling. Then turn the hand wheel anti-clockwise,the valve shaft and seal down,then closed the valves

Stainless Steel Sampling Valve Specification Chart

Size | 1/2",1-1/2" |

Connections | thread,clamp,weld |

Max.pressure | 10bar 145psi |

Min.pressure | Vacuum |

Temperature | -10℃ 50 F-120℃/248℃ |

Standard | 3A,ISO,DIN |

Body material | AISI1304, AISI316L |

Seal material | PTFE |

USAGR | Handle quick-opening type, handle wheel fine-turning type, pneumatic and hand-gas integrated four open mode |

Features

● Simple operation

● Simple structure

● Delicate appearance

● Fine craftsmanship

● Use the PTFE rubber durable and high purity

● Prevention of Pollution

● no dead angles

● Unique sealing structure

● Easy to clean

● Unique sealing structure, eliminate the sanitary blind corner. Easy to clean the sterilization process and Contamination free.

Application

The Sample valves are commonly used in industries such as food, chemical, pharmaceutical, cosmetics, beverage and biotechnology industries, where accurate sampling is crucial for quality control , analysis and testing purposes.

Working Principles

When the valve is open, it allows a small portion of the liquid to flow through and we get the sample collected and analyzed. We need to turn the hand wheel clockwise,the valve shaft and seal rise up, value is open for sampling. Then turn the hand wheel anti-clockwise,the valve shaft and seal down,then closed the valves

Feature and Specification

Stainless Steel Sampling Valve Specification Chart

Size | 1/2",1-1/2" |

Connections | thread,clamp,weld |

Max.pressure | 10bar 145psi |

Min.pressure | Vacuum |

Temperature | -10℃ 50 F-120℃/248℃ |

Standard | 3A,ISO,DIN |

Body material | AISI1304, AISI316L |

Seal material | PTFE |

USAGR | Handle quick-opening type, handle wheel fine-turning type, pneumatic and hand-gas integrated four open mode |

Features

● Simple operation

● Simple structure

● Delicate appearance

● Fine craftsmanship

● Use the PTFE rubber durable and high purity

● Prevention of Pollution

● no dead angles

● Unique sealing structure

● Easy to clean

● Unique sealing structure, eliminate the sanitary blind corner. Easy to clean the sterilization process and Contamination free.

Application

The Sample valves are commonly used in industries such as food, chemical, pharmaceutical, cosmetics, beverage and biotechnology industries, where accurate sampling is crucial for quality control , analysis and testing purposes.