| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless Steel Sanitary Butterfly Valve include manual, pneumatic, and electric types, with resilient or PTFE seats, 304/316/316L materials, strong sealing, corrosion resistance, stable flange connection, and reliable flow control for industrial pipelines.

The stainless steel triple offset flanged PTFE seat ring butterfly valve operates using a disc designed with three geometric offsets between the shaft, disc, and seat. During opening, the disc rotates away from the PTFE seat without sliding contact, reducing friction and wear. When closing, the disc gradually approaches the seat and achieves full sealing only at the final position. This design ensures tight shutoff, even under high pressure or temperature conditions. The flanged connection provides secure installation and accurate alignment in pipelines. The PTFE seat ring offers excellent chemical resistance and low torque operation, making the valve suitable for demanding industrial and corrosive fluid applications

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

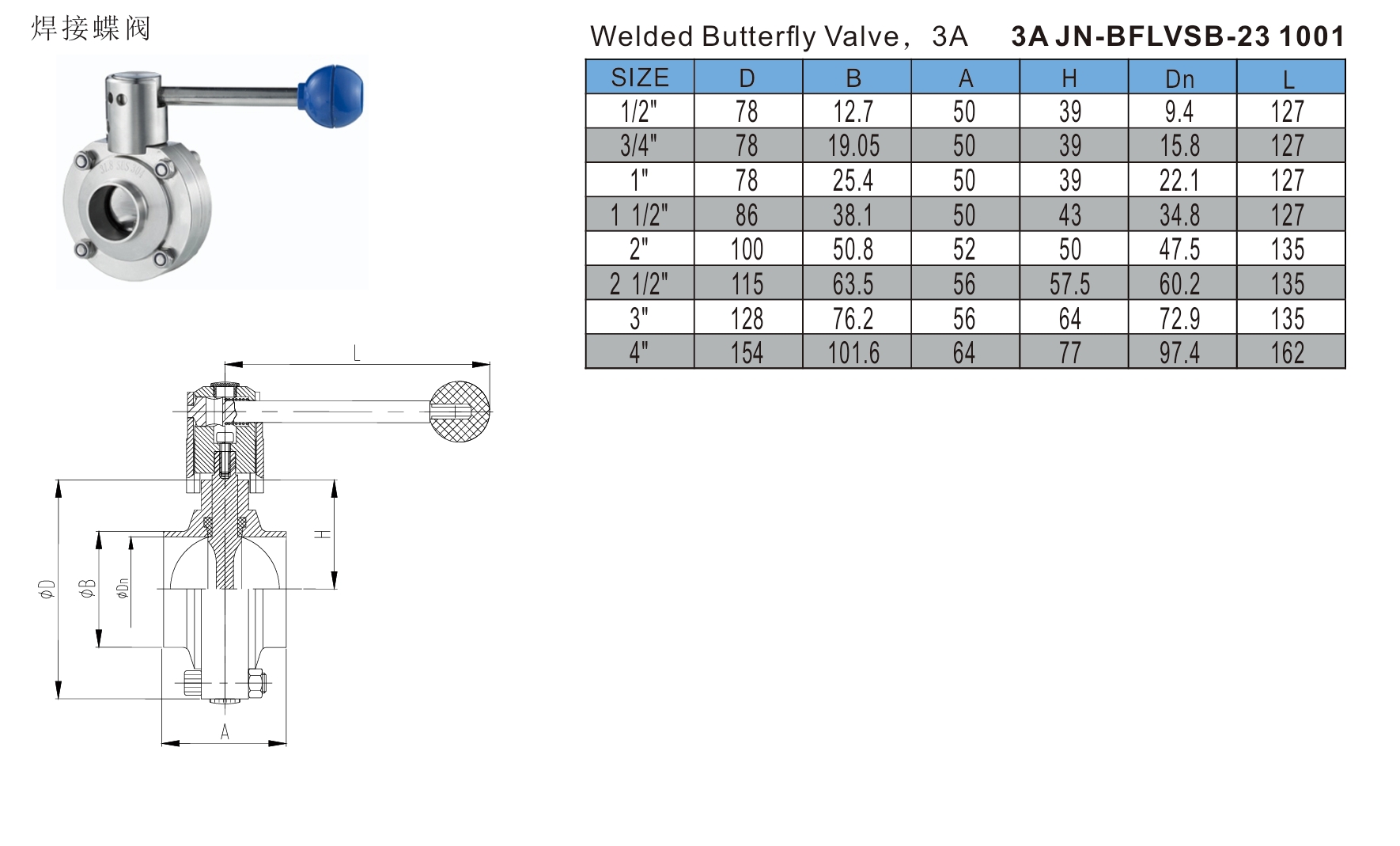

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

The triple offset design eliminates disc-to-seat friction during operation, significantly reducing wear, extending service life, and ensuring reliable sealing performance under frequent opening and closing conditions.

The PTFE seat ring provides excellent chemical resistance, low friction, and tight shutoff, making the valve suitable for corrosive media and demanding industrial process environments.

Stainless steel construction offers high mechanical strength, corrosion resistance, and long-term durability, supporting use in high-pressure, high-temperature, and harsh operating conditions.

The flanged connection ensures secure installation, accurate alignment, and stable sealing, making the valve reliable for large-diameter pipelines and critical flow control systems.

Sanitary Butterfly valve widely use in low and medium viscosity liquid for food and beverage, beer, dairy, pharmaceutical etc with high precision and purity requirements industries.

Working Principles

The stainless steel triple offset flanged PTFE seat ring butterfly valve operates using a disc designed with three geometric offsets between the shaft, disc, and seat. During opening, the disc rotates away from the PTFE seat without sliding contact, reducing friction and wear. When closing, the disc gradually approaches the seat and achieves full sealing only at the final position. This design ensures tight shutoff, even under high pressure or temperature conditions. The flanged connection provides secure installation and accurate alignment in pipelines. The PTFE seat ring offers excellent chemical resistance and low torque operation, making the valve suitable for demanding industrial and corrosive fluid applications

Feature and Specification

Stainless Steel Butterfly Valve Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Features

The triple offset design eliminates disc-to-seat friction during operation, significantly reducing wear, extending service life, and ensuring reliable sealing performance under frequent opening and closing conditions.

The PTFE seat ring provides excellent chemical resistance, low friction, and tight shutoff, making the valve suitable for corrosive media and demanding industrial process environments.

Stainless steel construction offers high mechanical strength, corrosion resistance, and long-term durability, supporting use in high-pressure, high-temperature, and harsh operating conditions.

The flanged connection ensures secure installation, accurate alignment, and stable sealing, making the valve reliable for large-diameter pipelines and critical flow control systems.

Application

Sanitary Butterfly valve widely use in low and medium viscosity liquid for food and beverage, beer, dairy, pharmaceutical etc with high precision and purity requirements industries.